(APP) American Polymer Products, Inc.

New Iberia, Louisiana, United States

(APP) American Polymer Products, Inc.

!

Industry leading custom molder of polyurethane products.

About (APP) American Polymer Products, Inc.

American Polymer Products, Inc. (APP) is an industry leading custom molder of polyurethane products. Products include VIV Shedding Pipeline Strakes, Temporary Abandonment (TA) Wellhead Caps Wear Pads, Rollers, Wheels, and Custom Products such as hydrocyclones, vibration absorbers, drilling tong safety handles, industrial gaskets, pipe support racks, pipe wipers, and clamp liners.

Description of Services

APP's engineering staff specializes in developing products to meet your specific needs. We also design and manufacture molds in-house to ensure the function and quality of the products. APP designs polyurethane for many applications, such as energy absorption, vibration dampening, and abrasion resistance.

APP has developed products that have had highly successful, proven histories in the following industries:

- Offshore Construction Industry

- Petroleum Industry

- Metal Processing and Mining Industries

- Transportation Industry

- Chemical Industry

APP's engineering department has developed a polyurethane product line with several unique properties. These products provide the following characteristics:

- excellent cut and abrasion resistance

- high tensile strength

- low coefficient of friction

- low compression set

- excellent resistance to environmental and chemical degradation

- easily bonded to metal and other plastics

What we do

Products:

a) VIV Shedding Strakes

The petroleum industry has been doing increasing amounts of development in deepwater areas. Drilling and production pipes used in deepwater applications are subject to a phenomenon known as Vortex Induced Vibrations (VIVs). When water flows around a cylinder, small vortices are formed on the leeward side, exciting vibrations within the pipeline. Since a deepwater pipeline is long and unsupported over most of its length, these vibrations significantly reduce its fatigue life.

APP has developed a unique system of helical strakes, which shed the vortices away from the pipeline, thereby minimizing VIVs. Our unique system has been developed through strict analysis and testing by our engineering staff. Through input from major gas and oil companies, engineering firms, and pipeline installation companies, APP has developed a strake system that not only efficiently shed vortices, but is also extremely durable. APP's strake system has the following benefits:

- Extremely durable polyurethane system, utilizing materials used in the offshore industry for over 15 years

- Ease of installation - we have worked with installation contractors to optimize installation time and cost

- Anti-fouling agents prevent marine growth from growing between and on strakes

- Structural testing in excess of 30,000 pounds (as shown in these images) have been performed on our strake system with ZERO FAILURES.

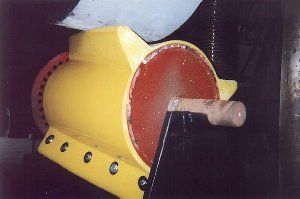

b) Lightweight Wellhead Temporary Abandonment Caps

The Lightweight Wellhead TA Cap was developed to reduce rig time. The cap is installed and removed with the use of a Remote Operated Vehicle (ROV).

The installation sequence is totally independent of additional equipment, eliminating the use of the drill string or other surface equipment such as winches, davits, or A-frames. The TA Cap can be installed while the rig is accomplishing other tasks.

The caps are manufactured from high quality polyurethane and the weight is extremely manageable with ROVs – both in air and in water. The caps are fitted with a stainless steel T-handle, and a 17H ROV hot stab receptacle for inhibitor injection. There are currently two sizes available - a 27 1/4 inch and a 36 3/4 inch, with virtually unlimited ability for additional sizes.

APP Lightweight Wellhead TA Cap versus Conventional Methods:

- Original cost for the cap is substantially lower than conventional aluminum or steel TA Caps

- Can be installed and removed using ROVs only - No additional wenches or rigging is required

- No surface equipment required for installation - Conventional systems use separate winches, which require additional time, equipment, and personnel

- Conventional systems require the rig to be in close proximity to the well during the operation - Using this ROV installable TA Cap, the cap is carried down by the ROV and installed or removed while the rig is performing other tasks (such as installing or removing anchors or lowering or retrieving the BOP off location).

- Material is impervious to saltwater degradation

- Caps are manufactured in bright yellow for high visibility underwater (other colors are available)

- TA Caps are self sealing to the wellhead - no additional clamping or gasket material required

c) Wear Pads

APP wear pads are custom molded to fit a wide variety of applications. From forklift pads to boatlanding rubstrips, mounting on flat bar to pipes, each wear pad is produced to tight tolerances to fit as needed. High quality polyurethane wear pads provide excellent abrasion resistance, excellent structural strength, and high resistance to the environment and to chemicals. Other properties, such as low coefficient of friction, can also be incorporated into the design.

APP wear pads are used extensively in many industries, such as the Offshore Construction Industry, Petroleum Industry, Pipeline Industry, and Metal Processing Industry.

d) Rollers & Wheels

APP has developed an extensive line of straight and V-rollers for a variety of applications. Our polyurethane rollers are designed to withstand high loads and abrasive interfaces, such as pipeline forming and coating plants. Our advanced polyurethane materials are able to withstand significantly more abuse than rubber or metal rollers.

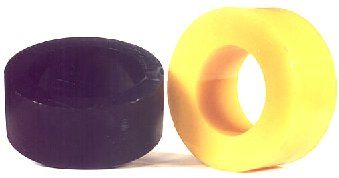

e) Hammer Cushions

APP has designed and manufactured extended life hammer cushions for piling drivers used in several industries, such as the offshore construction industry, petroleum and gas drilling industry, road and bridge construction, commercial building construction, and many others. The polyurethane used in these applications has superior hysteresis breakdown resistance, and can be designed for a large variety of spring constant and dampening requirements.