Core Mineralogy Labs

Broussard, Louisiana, United States

Core Mineralogy Labs

!

Full-Service Petroleum Laboratory. Wellbore Forensic Specialists. XRD, EDX, XRF, SEM, LPSA, FTIR GC, TOC.

About Core Mineralogy Labs

Core Mineralogy is a provider of analytical services, including XRD, EDX, XRF, SEM, LPSA, FTIR, GCMS, ICP, TOC, TSS, and thin sectioning. Mansour Rahmatian, our senior reservoir mineralogist, has over thirty years of industry experience in wellbore forensic investigation and formation evaluation.

Description of Services

SERVICES:

- XRD

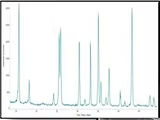

X-Ray Diffraction Analysis

X-ray diffraction analysis is a semi-quantitative method used to determine a sample’s mineralogical composition, crystal structure, and compositional percentages.

CMI uses rapid and thorough powder diffraction techniques for sample analysis. Mineral identification of a sample is performed using the International Center for Diffraction Data (ICDD) card file data.

Mineral phase quantification is performed utilizing the relative intensity ratio (RIR) method of analysis, currently utilizing MDI’s Jade 2010 analytical data interpretation software.

CMI offers a rapid turn around times of 3 - 5 days, with an optional rate increases for rush (24 hours or less) samples and sample analysis outside of normal work hours.

XRD applications services offered at CMI include:

Bulk mineralogy (determination of sample mineral composition)

Clay mineralogy ID, including air dried, heat treated, and ethylene glycol vapor treated

Scale Analysis to improve production and flow assurances.

Identification of low resistivity pay zones via clays containing mineralogically bound water and other conductive minerals such as zeolites

Determination of grain density to correct log–driven porosity, resulting in a more accurate estimate of hydrocarbons-in-place

Combined with EDX data analysis, which renders semi-quantitative elemental compositional data, skilled interpretation XRD analysis is a very powerful problem solving tool.

- XRF & EDX

X-Ray Fluorescence Spectrometry

- LPSA

Laser Particle Size Distribution Analysis

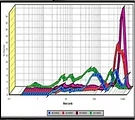

Laser particle size distribution analysis (LPSA) is a highly efficient, extremely rapid, very precise optical sieve technique method for particle size analysis. CMI laboratories uses the Microtrac S-3500 system and software for its data acquisition with applications such as:

• Graphical representation of the particle distribution based on a variety of physical characteristics, including volume and surface area.

• Data reported in both Micron and US Mesh scales.

• For “sand control”, the screen and gravel sizes can be selected based on laser data obtained from the analysis of sidewall core, conventional core, or drill cuttings samples.

• Monitoring of active drilling mud particle size distribution.

• Monitoring the efficiency of a water treatment vessel by comparing the particle size data of an inlet sample versus an outlet sample.

• Selecting proper filter sizes for water disposal wells or water flooding projects.

• Quality control of oil field products or other industrial products

- WELLFLOW

WELLFLOW ASSURANCE

- BARIUM SULFATE SOLUBILITY

For over a decade, Core Mineralogy Labs has acted as an independent laboratory to study methods of barium sulfate scale (BSS) build up removal. Having amassed and tested a number of widely available chemicals, both generic and brand name in origin, CMI has perfected techniques of in-house chemical

application to minimize the need for more expensive and damaging techniques. As oil and gas wells continue to reach greater depths, dissolved barium becomes an even more impactful issue to both the producibility and economic efficiency of oil and gas wells offshore in the Gulf of Mexico.

Listed below are a number applications for scale removing chemicals that can be particularly cost effective and non-damaging:

1. Removing tight spots in the production tubing created by barium sulfate scale bridging that can significantly reduce production rates

2. Removing excessive amounts of BSS build-up preventing the regulatory testing of surface-controlled, sub-surface safety valves (SCSSV) via Slickline

3. Increasing the efficiency of BSS milling after an overnight soak

4. Cleaning a gravel pack assembly, minimizing the potential for the corrosion of the metallurgy or damaging the formation permeability, a common issue with an acid option

In terms of field results, if the temperature of the affected spot is around 140°F, a minimum of 30-35% solubility is expected, where as if the temperature is significantly higher (175-200ºF), then a solubility of 60-85% is very common using certain chemicals.

- WELLBORE STABILITY

- THIN-SECTION PETROGRAPHY

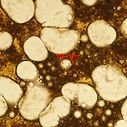

Example of a Thin Section Description Report

Ø = 6.8%. Ka = 4.55mD. MGS = 308 Microns

Thin Section Descriptions: Fine to medium-grained, moderately well sorted, relative clean, quartz-rich (70%) sandstone.

The porosity has a patchy distribution, with cluster of high porosity in one place and relatively low porosity in others.

The large pores (P) seen in image A and B are most probably secondary pores generated by the selective dissolution

of some unstable grains. The green arrow in image A points to an artificial microfracture created along a pre-existing stress line.

The red arrow in image C points to a channel-like elongated pore space. Thin section photomicrograph D & F shows colorful,

high birefringence anhydrite minerals that locally fill the pore spaces, contributing to the patchy distribution of porosity.

- SANDING CONTROL

Case History:

A private oil company experienced sand failure in an adjacent well to this offshore Louisiana well and wanted to explore ways to complete this well without a gravel pack, resulting in a savings of about $275,000.00.

The well data, along with detailed thin section petrographic analysis of four sidewall core samples, was utilized to recognize low cohesive failure zones (F) by estimating the average sheer stress, giving the client two options for avoiding the need for sand control via gravel pack:

• Option 1: Avoid perforating two thin zones marked as (F). This option was deemed undesirable by the client.

• Option 2: Keep drawdown below 100 PSI for the first few weeks of the initial well production, then gradually increase the pressure incrementally to a maximum of 400 PSI.

This second option was employed, and no sands were produced during the first two years of production, as monitored by CMI

- SEM

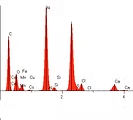

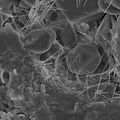

Scanning Electron Microscope.

SEM Description:

SEM image C shows an enlargement of the red rectangle in image B, where many of the pore walls are bridged by illite fibers. The yellow arrows in image B & D point to a glob of bitumen (dead oil). The EDX spectrum obtained from this bitumen reveals a high percentage of carbon (75%), and a significant amount of sulfur (4.9%), and 3.10% iron as components of the bitumen. A blue arrow in image D points to a tiny ferroan dolomite rhomb. Image E shows the detail of illite fiber as seen in the green rectangular area in image C. Image F shows long whiskers of illite. In the EDX spectrum taken from these illite fibers, a high relative percentages of potassium (9.546%), significant amount of chlorine (1.828%), and sodium (1.076%) are notable. The water-wet illite fibers, as seen in image C & E, can create an electrically conductive network throughout this sandstone, resulting in a significant reduction in the resistivity log responses in this obviously oil productive zone (based on the production data).

- EMULSIONS

Troubleshooting Emulsion Issues.

- SAMPLE STORAGE

- FORMATION DAMAGE