dig | Dolan Integration Group

Westminster, Colorado, United States

dig | Dolan Integration Group

!

Geochemistry for Energy.

About dig | Dolan Integration Group

Our Story

When you contemplate starting a business in the oil and gas service sector, it is important to understand multiple economic factors. The boom-bust cycle that defines the energy industry throughout its history requires you to enter this industry with a clear vision. Diversifying your own and your company’s skill set allows success in many economic climates.

Pre-2000s

The vision for Dolan Integration Group was incubated during a volatile economic climate. U.S. imports of oil and gas were rising, and the geopolitical implications were vast. Studying and knowing the role of geochemistry in the oil and gas industry has always allowed diversification of skills. Job experiences with Mobil and ExxonMobil developed skills in exploration, development, production and environmental health and safety. If you want to be a boom-bust cycle survivor, diversifying the skill set is critical.

2000-2010

In 2006, Dolan Integration Group opened its doors with a clear goal to remain diversified in our skill set. The nascent shale revolution was in full swing and organic geochemistry was a high demand skill. A keen realization that organic-rich source rocks (aka shales) were now the most important aspect of the petroleum system was forming in the industry. An emphasis on oil versus gas prediction in shale plays was being developed by DIG and U.S. oil and gas operators. This period was defined by a renewed interest oil and gas and exploration in shale plays in the United States and interest in DIG exploration products exploded. DIG provided critical expertise to reduce risk and predict success during this time. U.S. oil and gas operators agreed.

2010-2020

Development of oil and gas resources that were discovered in the early part of this century in the U.S. Lower 48 also require geochemical and laboratory expertise. DIG began to develop a laboratory that would concentrate on the hydrocarbon fluids that were now flowing from all those newly discovered oil and gas wells. The DIG fluids laboratory began operating in 2012. By 2014, the DIG laboratory was fully functional and U.S. oil and gas production had ascended to the top rank in the world (EIA, 2021). Despite predictions of peak oil just a few years earlier, the U.S. was now the number one producer of oil and gas in the world. A diminished dependency on foreign sources of energy changed the geopolitical landscape. DIG supported an industry that had helped to kick the habit of foreign oil dependency. Exploration, development, and production of home-grown resources were being supported by DIG’s comprehensive services. Again, the ability to anticipate the emphasis on U.S oil and gas production helped guide DIG through the tumultuous price volatility. Supply went up and prices collapsed. DIG remained a steady supplier of services that continued to be in high-demand. As a result of the industry focus on oil and gas production, U.S. produced hydrocarbon fluids were the new king of energy and DIG was poised to provide geochemical expertise to support the production of these fluids.

2020s

With great success in oil and gas exploration and development came a growing and robust regulatory environment. DIG’s chemical engineers and geologists were poised for this shift. As it turns out, the laboratory regime for analyzing oil and gas dovetails very well into the fluid forensics and fingerprinting of hydrocarbon fluids. Whether those fluids are being produced from an oil and gas well or impacting the near sub-surface or surface hydrologic systems, well integrity is a critical part of the new regulation. We have the tools to support and provide critical mitigation strategies to our clients.

Our Future Mission

As we move toward the future, DIG is well-positioned for success. Our suite of services will continue to serve the oil and gas industry. We understand the importance of all energy sources and support the responsible stewards of our environment. Our experience has naturally expanded toward natural gas storage and carbon capture and storage monitoring, validation, and assessment. The infrastructure of many of these subsurface systems are well known to DIG scientists and engineers. We continue to conduct our business under our mantra of operational, technical, and personal integrity. Continually diversifying our skills allows us to provide unsurpassed customer service to all the industries that we serve in an environmentally sustainable way.

Description of Services

Dolan Integration Group provides its services and backs it up with expert knowledge. There are many topics that may be new to an energy professional. DIG can help you understand the important aspects of a service no matter your level of expertise.

Here are a few examples:

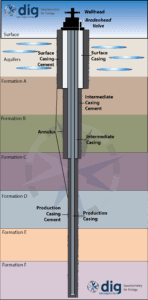

a) Bradenhead Pressure

We use the term Bradenhead Pressure to describe casing head pressure. As a result, the term bradenhead pressure (or casing head pressure) is similar to the term “sustained casing pressure”. Additionally, “sustained annular pressure” is another term we commonly use. In Canada, we have encountered “surface casing vent flow” and “sustained annular pressure”.

It’s all the same process

Well Design Schematic with Bradenhead Valve

For regulatory compliance, we are describing the same process using these general terms. That is, the undesirable buildup of pressure on any of the annuli in an oil and gas well. However, the Colorado Oil and Gas Conservation Commission (COGCC) specifically defines the bradenhead as the annulus between the surface casing and the next innermost casing in their regulations. Presumably, this is done to simplify the description of this annulus and the buildup of pressure in this annulus. Importantly, in Colorado, bradenhead tests refer to tests that assess the presence of surface casing pressure on oil and gas wells and bradenhead pressure is analogous to surface casing pressure. (Lackey, et al., 2017) That is to say, in some other development areas this process is known as:

- sustained casing pressure

- sustained annular pressure

- casing head pressure

- surface casing vent flow

b) Underground Natural Gas Storage Monitoring

Injecting gas into the subsurface can be done for many reasons. The natural gas that is injected into the subsurface can be made up of number of molecular compositions. Hydrocarbon gases are often stored in reclaimed oil and gas reservoirs, aquifers, and salt caverns in Underground Natural Gas Storage Facilities (UNGSFs). Today, geoscientists and engineers are also developing systems and infrastructure to capture greenhouse gases (GHGs), like carbon dioxide (CO2).

The reasons for storing and capturing natural gas are varied and all extremely important. UNGSFs play an important role in current energy supply and distribution systems, The main goal of UNGSFs is to keep consumer energy costs consistent and predictable. DIG works with many pipeline operators to help gas solve storage issues.

Capturing CO2 has become an important part of sustainable practices for many energy utilities. Permanent storage or retaining the gas for future utilization can be the reason for injection of CO2. The reasons are variable, but the primary objective is to retain all the gas in the subsurface reservoir. Whether the goal is to sequester greenhouse gases (GHGs) or utilize the gases for another purpose, the main goal is to have a competent underground reservoir that does not leak to the atmosphere.

Monitoring the underground gas capture and storage facilities and infrastructure is where DIG excels. Subsurface geochemistry is what we do. As geochemists and chemical engineers, DIG understands that the gases that are involved in storage and capture subsurface systems can contain multiple molecular components that all must be considered for successful retention or utilization. Well integrity must be monitored and DIG possesses the analytical skills and expertise to do it.

In most cases, the common denominator between these two systems is capture. If operators are building the infrastructure to capture the gas, no matter what the composition, it is most important that the gas does not leak to the atmosphere. Once it is injected, the primary objective is to hold the gas in the ground. Monitoring the efficiency of the capture is critical.

c) Carbon Capture Monitoring

Setting a Chemical Baseline

Monitor – Verification – Assessment

Carbon Capture, Utilization and Storage (CCUS) or Carbon Capture and Storage (CCS). DIG thinks that the key word here is “capture”.

Never have we seen the adoption of an idea take hold so completely. Tax credit programs like 45Q have helped. As a result, this technology may be new to most of our colleagues. Dolan Integration Group (DIG) has been monitoring underground storage facilities for years. As it turns out, stable isotopes of carbon (δ13C) are a pretty handy tool for monitoring CCS systems and carbon capture. We are proud to say that we offer this important technology to the industry for monitoring, verifying and assessing the success of capture these gases.

In the U.S., new federal 45Q tax credits have been made available for the entities that can capture carbon as CO2 permanently. In addition, a credit is offered to utilize CO2 in enhanced oil recovery (EOR) operations. Those who have taken advantage of these credits know that significant revenues can be added to existing revenue streams. This has led to a boom in identifying good geologic reservoir candidates to capture and store CO2. Importantly, these systems must be monitored.

If you are currently evaluating CCUS or CCS opportunities, it is extremely important to talk to DIG early about how we monitor the efficiency of capture in these systems. We can help set baseline and monitor your infrastructure.

Setting a baseline early will be critical to monitoring your success. First, designing the well infrastructure for repeatable sampling. Second, monitoring the injection gas. Third, understanding subsurface chemistry will all play a role in your continued success.

Talk to the experts today. We can provide the latest technological know-how in a complex and quickly changing environment.

d) QuickStart Maturity™ Modeling

Dolan Integration Group offers multiple options to help evaluate your current and future properties in the Energy Sector. DIG has used petroleum systems models for decades to help our clients succeed. We created the QuickStart Maturity™ Models to assist geologists and engineers with understanding heat distribution in the subsurface by modeling depositional and subsidence history. These 4D models have multiple applications in the exploration, development, production, and environmental aspects of hydrocarbon distribution. The QuickStart Maturity Studies can help assess fluid quality and can be predictive regarding the presence of oil, gas condensate, or gas fluids as well as changes over time of these fluids due to subsidence variability in sedimentary basins.

Dolan Integration Group has constructed regional maturity models for most of the major petroleum basins in the onshore U.S. lower 48. In addition, we have modeled basins in Canada, Mexico, Australia, South America, and Asia. These QuickStart Maturity Models are useful for high grading proven and emerging conventional and unconventional plays. Multiple horizons per basin have modeled (predicted) maturity which is critical to the evaluation of potential acquisitions and divestments. For unconventional plays, these models have proven to be accurate over several years in identifying areas which are prospective for oil, wet gas, and dry gas. Some basins have been updated multiple times as new rock maturity and other drilling data becomes available.

QuickStart Maturity Models are also used to support more detailed subregional and local geochemical studies. Uses of the QuickStart Maturity Studies can be seen in the following video featuring the Powder River and Denver Basins.

DIG strives to accomplish three goals:

- Formulate cost effective geochemical evaluations by working closely with the client.

- Technical excellence in a timely manner.

- Be responsive to our clients’ needs.

These studies support our clients’ goal of assessing petroleum potential for the entire sedimentary section. Structural horizons, rock maturity and temperature gradient data is input to produce a calibrated basin wide maturity model. QuickStart Maturity Studies require the following inputs:

- Regional structural surfaces

- Tertiary erosion map

- Temperature gradient from bottom hole temperatures map

- Rock maturity data (primarily vitrinite reflectance and pyrolysis)

- Temperature gradient calibrated to rock maturity

These studies provide an interpretation of several important features of unconventional plays. DIG QuickStart studies include the following outputs:

- Regional structural surfaces

- Tertiary erosion map

- Calibrated temperature gradient map used for modeling

- Raw rock maturity data (vitrinite reflectance and pyrolysis)

- Vitrinite reflectance averaged by well and formation (edited for quality control)

- Vitrinite reflectance equivalence (VRE) from pyrolysis (Tmax) averaged by well and formation (edited for quality control)

- TOC Data

- Measured TOC and original TOC maps (selected horizons)

- Gross and net source isopach maps (selected horizons)

- Predicted GOR and condensate yield maps (selected horizons)

- Present day formation temperature maps (selected horizons)

What we do

Dolan Integration Group (DIG) was founded to assist our clients with a full array of energy-related consulting, database and laboratory services. Our mission is to provide geologic, geochemical and engineering services to help reduce the costs associated with many aspects of fossil and renewable energy.

DIG provides technical expertise to review and develop risk assessment programs in the upstream, midstream and downstream energy industries. Our expertise in organic geochemistry, geology and engineering has required fundamental knowledge of laboratory protocol required to perform the necessary laboratory analyses on rocks, oil, gases and waters. This is a critical function to understand the evolution of technical advances in these industries.

It is also our mission to provide the energy industry innovative technologies to continue to operate safely, environmentally responsibly and within the social contract.

Life at dig | Dolan Integration Group

DIG core principles are Integrity, Service, Development, and Spirit. We put a great deal of emphasis on the importance of upholding these values.

Integrity

- Operational Integrity – We will conduct ourselves in a professional manner and at the highest level of integrity. Our success depends upon this principle.

- Technical Integrity – The products that we provide our clientele are always to be considered at the highest levels of technical and scientific merit. Technical quality is our trademark.

- Personal Integrity – We will conduct ourselves in the highest ethical standard. If we serve our clients in this manner, our own success is assured.

Service

- Our clients’ needs are respected and acted upon. Customer service should be foremost in the mind of every DIG associate.

- Mutual respect of all DIG associates keeps us consistent in our actions and deeds. No DIG associate is more or less important than any other.

- Teamwork is critical to our continued growth and success. Keeping the lines of communication open and honest provides an environment of trust and respect. We are the DIG Team.

Development

- We are all responsible for the development of our own integrity and success. This individual success will quickly translate into the collective development that we all need to succeed.

- DIG recognizes the need to create an environment of continued learning. We are not judged by mistakes but by our motivation for continued learning and to overcome adversity.

- Growth is available at DIG both professionally and personally. Our commitment is to provide the atmosphere for creativity and innovation. Innovation drives our continued success.

Spirit

- We strive to be entrepreneurial. We seek answers to problems we encounter. Our available resources are vast.

- We are proud of our achievements. We celebrate our clients’ successes, our own experiences, and our colleagues’ triumphs.