Drill2Frac

Katy, TX, United States

Drill2Frac

!

Your near-wellbore data solution. Near well-bore insights to maximize productivity.

About Drill2Frac

Delivering near-wellbore analysis and actionable completion insights since 2014.

Drill2Frac uses patented technology and advanced methodologies to help oil and gas operators optimize perforation placement and fracture growth during completion operations.

To date, we’ve applied our analysis and expertise in wells across all U.S. unconventional plays, as well as in Canada and Argentina.

A wealth of valuable data. And the guidance to go with it.

With Drill2Frac in your corner, you’ll never be left with a mountain of data to decipher on your own. We’re with you every step of the way. Once we’ve delivered your new, high-resolution data insights, our team of experts will remain available to provide answers and understanding – from planning through completions and production.

Our integrated team specializes in all things data, software, analytics, engineering, geology and petrophysics – and we’re passionate about delivering superior data and exceptional service. Every day and in every endeavor, we take pride in our ability to innovate, inform and promote continued success in the oil and gas industry.

A superior customer experience, built on a positive work environment.

Happy, engaged employees are essential to our ability to deliver exceptional service. Drill2Frac is a minority-owned company, and we proudly uphold the principles of equal-opportunity employment. We are dedicated to providing fair employment opportunities to all employees and applicants, in compliance with relevant federal, state, and local laws.

We’re committed to providing our employees with a supportive work environment, optimal work-life balance (with flexibility to work remotely when possible), and rewarding compensation and benefits packages. In addition, to foster a spirit of giving back, each employee receives eight hours per year of paid time off for community volunteering. Drill2Frac is a great place to work, and it shows in the strong relationships we’ve built with clients across the globe.

Description of Services

Your near-wellbore data solution.

Identifying changes in near-wellbore rock properties – and understanding how these changes can affect the success of your completions – are some of the biggest challenges shale operators face. Drill2Frac is here to help.

With no additional downhole tools, no operational interruptions, and zero added risk, we provide high-resolution near-wellbore data and comprehensive analysis to:

- Dramatically improve overall well efficiency and performance – from planning through production

- Optimize well spacing and target completion landing zones to enhance asset development

- Achieve optimal well uniformity and cluster efficiency using dynamic completion-design simulations

- Assess and mitigate the risk of frac hits

Actionable, reliable data to drive your completion success.

Drill2Frac’s data-driven insights are cost-effective for every well. Using existing drilling data as the foundation of our innovative near-wellbore analyses, we deliver high-resolution data that enables operators to proactively fine-tune their completions with stage-by-stage precision.

The foundation of our insights is the OmniLog® correlative data visualization. This side-by-side visualization tool adds greater depth and understanding to our proprietary RockMSE® analysis – which uses a corrected, calculated value of mechanical specific energy to evaluate near-wellbore rock characteristics. By looking at each piece of information from multiple angles, you’ll be better informed about how reservoir properties change along the lateral.

A proactive, cost effective approach.

Most solutions provide data only after the well has been completed. As a result, you can’t use that information to guide completion designs and improve well performance. On top of that, traditional solutions often require expensive, invasive tools that add cost and downtime to completion operations.

Drill2Frac is different. We deliver insights before completion operations begin. Using data that’s readily available after the wellbore is drilled, we take a cost-effective, proactive approach that doesn’t require additional downhole tools and won’t interrupt your schedule.

Gain a stronger understanding of your completion dynamics.

What we do

Key Technologies:

- OmniLog®

OmniLog® Correlative Data Analysis

Proactive, actionable and reliable data on every well.

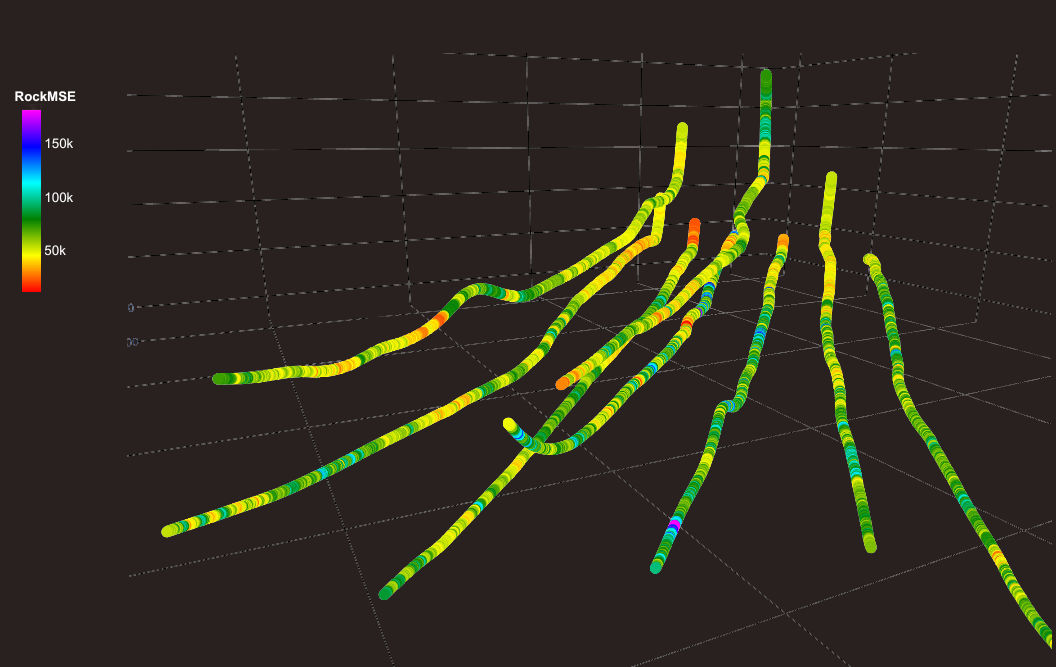

Drill2Frac’s OmniLog correlative data visualization enables operators to optimize well performance by adapting their completions to the varying rock properties along the wellbore. The foundation of this correlative data visualization is our RockMSE analysis, which uses existing drilling data to evaluate near-wellbore rock characteristics.

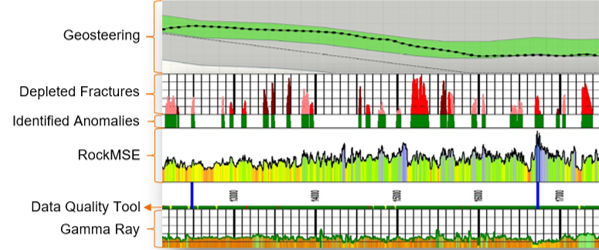

The OmniLog visualization displays RockMSE data alongside other important pieces of data collected at the drilling rig – such as cuttings analysis, mud gas analysis, gamma ray (GR) readings, mud gains/losses and geosteering information. To add even more value to those datasets, we can include data obtained from our proprietary depleted fracture identification (DFI) analysis.

A unique wellbore perspective. Exceptional completion insight.

By stacking crucial data logs for easy, side-by-side comparison, our OmniLog visualization gives you an unprecedented perspective into downhole wellbore dynamics. This exclusive Drill2Frac service provides a detailed profile of the lateral in fractured wells – correlating multiple data signatures to optimize cluster efficiency, increase well productivity and reduce costs.

Empowered by clearly visible correlations between different diagnostics, you’ll gain a much stronger understanding of how wellbore heterogeneity can affect your completion success.

- RockMSE®

RockMSE® Near-Wellbore Analysis

A higher-resolution view of rock properties along the wellbore. No need to deploy expensive downhole tools.

Drill2Frac’s RockMSE service provides valuable information about near-wellbore rock properties – and delivers higher ROI than traditional downhole data-acquisition methods.

Don’t settle for high-priced technologies and low-resolution data.

Microseismic readings, permanently deployed fiber-optic cable, core sampling, and downhole pressure gauges can be prohibitively costly, invasive and time-consuming.

And, while mechanical specific energy (MSE) data is often used as a less costly and invasive way to estimate near-wellbore rock properties, it doesn’t paint a very clear picture. That’s because the raw drilling data used to calculate MSE is loaded with noise caused by bit wear, geosteering effects and multiple other drilling dysfunctions.

RockMSE analysis delivers a superior solution.

Our proprietary process filters raw drilling data to remove drilling events, artifacts and noise. The result is a cost-conscious, noninvasive solution to help you achieve optimal well uniformity, improved cluster efficiency and increased production.

Using existing drilling data that’s gathered on every well, RockMSE analysis characterizes unconventional wellbores by:

- Identifying near-wellbore rock properties, wellbore heterogeneity, and localized depleted fractures

- Fine-tuning landing targets by showing detailed subsurface geology changes along the lateral

- Illustrating the effects of geology on fracture growth to optimize well spacing

- Adding resolution to existing rock data, such as cuttings analysis, gamma ray (GR) readings, mud-log lithology, and mud-log gases.

- DFI®

Depleted Fracture Identification

Pinpoint areas of localized depletion that can cause harmful fracture-driven interactions.

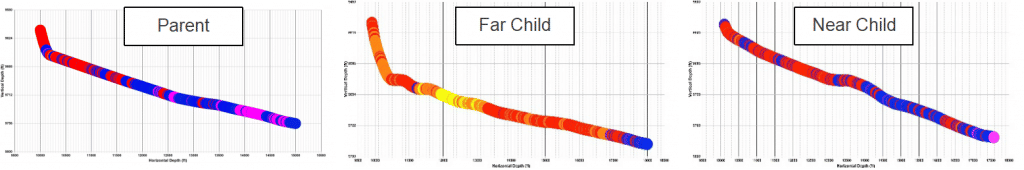

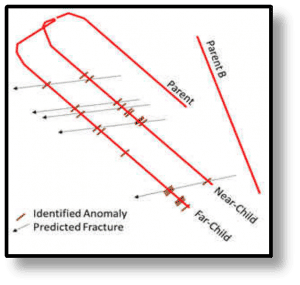

Parent-child well interactions often lead to compromised completions that can significantly hinder production from both wells. Of course, there are plenty of techniques to evaluate this interwell communication during or after the fracturing treatment. But by that point, the potential damage is already done.

Wouldn’t you rather take a proactive approach – and be better informed to prevent or mitigate fracture interactions – by identifying areas of localized depletion beforehand?

The depleted fracture indentification (DFI) process is different.

Our DFI analysis is the only method on the market that can predict potential frac hits by pinpointing areas of localized depletion in the wellbore. These areas are most often associated with depleted fractures connected to a parent well, and restimulating them can exponentially increase the likelihood of causing an interaction with the parent well.

That’s where our proprietary DFI process comes in. By analyzing your existing drilling data to identify the precise locations of these vulnerable communications between wells, it provides actionable insights to help:

- Predict and mitigate potential frac hits from new completions

- Assess fracture growth from the parent well

- Optimize well spacing

- Reduce completion costs

- Enhance your understanding of cluster efficiency (when integrated with FlowFX™ near-wellbore simulator)

Avoid depleted fractures without bypassing valuable reserves.

Precise targeting gives you unprecedented power to reduce completion risks by avoiding only the problem areas – without having to avoid significant sections of the lateral and reduce your well’s potential in the process.

- PerfAct®

PerfAct® Analysis

The fast, accurate, repeatable way to optimize perf designs.

Drill2Frac’s PerfAct analysis provides targeted perforation designs to enhance efficiency and effectiveness. Based on operator-defined constraints – such as stage length, cluster spacing and proposed number of clusters – the PerfAct process can quickly and repeatedly deliver multiple perf-design options. This enables you to easily compare the results of these different designs, choose the best-performing option, reduce completion costs, and improve overall well productivity in the process.

All options considered. Everything in the proper place.

Accounting for wellbore heterogeneity and rock-strength profiles, PerfAct analysis provides detailed insights to arrange and space perforations to achieve the best possible completion performance.

Going into even greater detail, the PerfAct process evaluates other contributing data – such as gamma ray readings, gas detections and mass spectroscopy. Then, using sophisticated computer algorithms, it selectively places perforations in areas of similar rock properties.

To further refine the perf design, many operators choose to integrate our depleted fracture identification (DFI®) process with PerfAct services, which helps to identify and avoid areas of localized depletion along the lateral.

We’re with you every step of the way.

As an added layer of assurance, Drill2Frac basin experts always review final PerfAct recommendations before delivery. If our eyes-on assessments determine that adjustments to a proposed PerfAct design will further improve cluster efficiency and performance, we’ve got you covered – and we’ll be on hand for post-completion reviews and beyond.

Adjust your baseline completion plan. Raise your expectations.

- FlowFXTM

FlowFX™ Near-Wellbore Simulator

Data-driven insights to proactively model and assess completion designs.

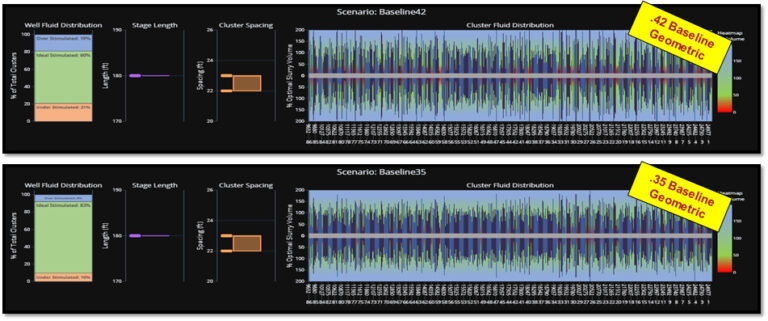

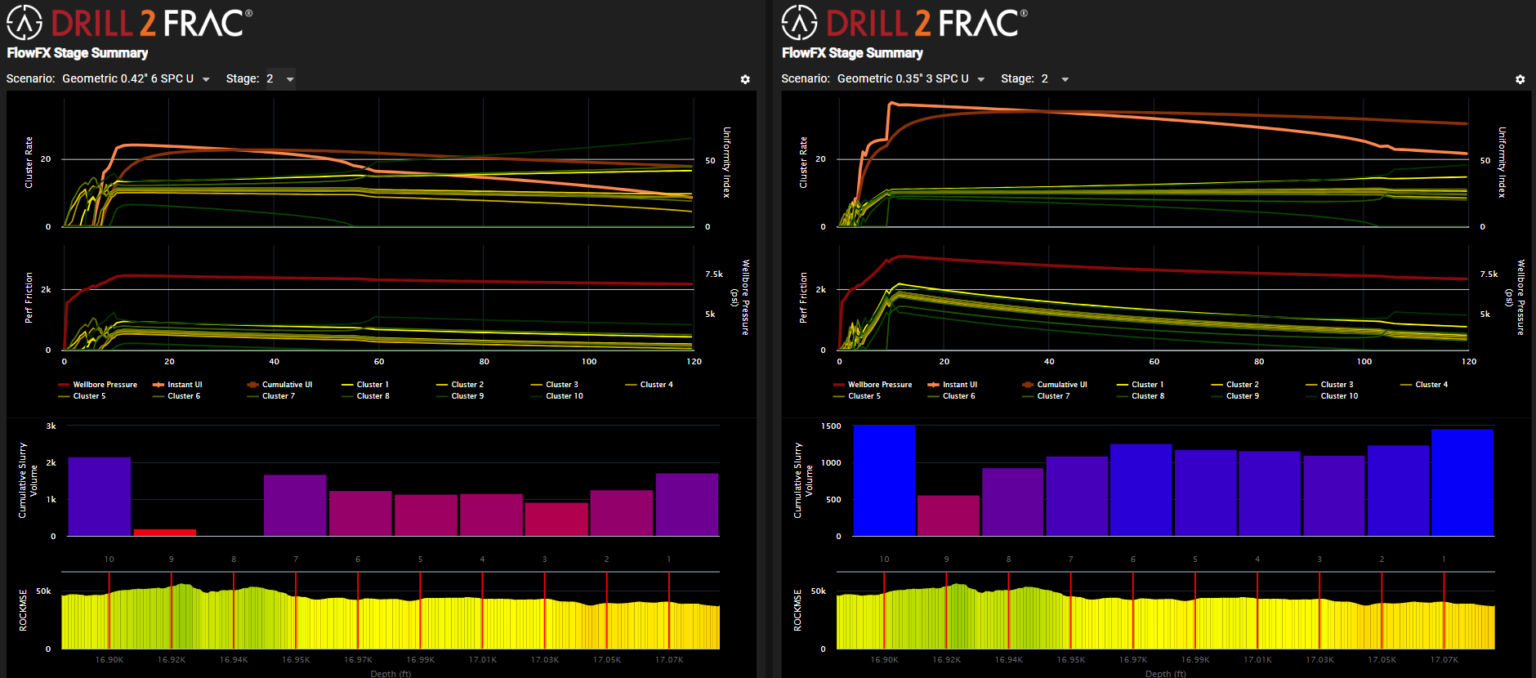

Our cloud-based FlowFX simulation software enables Drill2Frac experts to model the impacts of manipulating various completion-design parameters – according to actual near-wellbore rock properties along the lateral.

Before you begin to execute in the field, this information gives you the unique ability to compare how different combinations of design changes will affect fluid distribution and treatment pressures among perforation clusters.

Stage by stage, you’ll be better equipped to answer critical questions that can affect your completion success:

- Is there sufficient or excessive perforation friction?

- Are clusters competing because they’re placed too close together?

- Can you add more clusters to increase stage lengths and reduce costs?

- What is the impact of changing perf guns (charge types or phasing)?

- What is the impact of an optimized completion?

Here’s what you get from the FlowFX near-wellbore simulator.

Guided by FlowFX modeling results, you can create optimized completion designs tailored to each well’s unique characteristics. (Simulation software is not downloadable and is accessible only to Drill2Frac analysts.)

Our innovative simulation process:

- Dynamically models each perforation cluster along the wellbore

- Uses actual mechanical properties, based on our proprietary RockMSE® calculations

- Calculates dynamic erosion from proppant flow over time

- Estimates dynamic changes in breakdown pressure at each cluster

- Calculates impact of stress shadow – in both current and previous stages

- Varies individual hole sizes based on perforation phasing

- Enables modeling various combinations of completion parameters

- Accounts for the impact of localized depletion around existing fractures

- Can be calibrated with additional diagnostic data, including geomechanical stress profiles, downhole camera images, and fiber-optic data.

Here’s how FlowFX near-wellbore simulation works.

After characterizing near-wellbore rock properties based on detailed RockMSE calculations, we use FlowFX software to model the effects of adjusting many different completion parameters, including:

- Stage length

- Number of clusters per stage

- Cluster placement

- Number of perforations per cluster

- Perforation phasing

- Perforation diameters

- Pump rates

- StageStatsSM

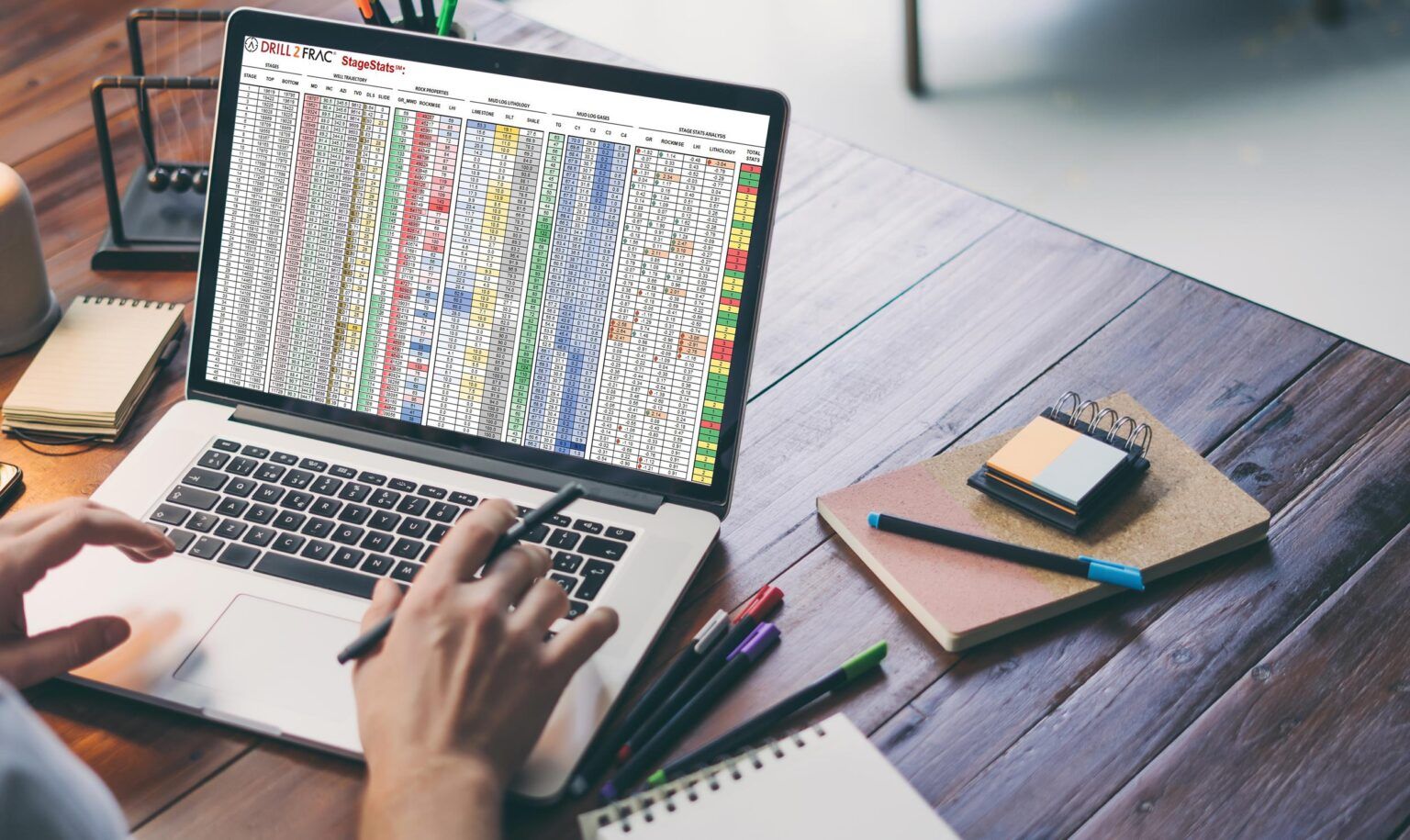

StageStatsSM Analysis

Stage-by-stage precompletion insights to boost treatment performance.

Drill2Frac’s StageStats analysis classifies each fracturing stage along the wellbore, based on an average of the near-wellbore rock properties within that stage. This analysis empowers you to better understand how those properties vary from stage to stage.

How do the different stages in your wellbore stack up?

The StageStats assessment gives you a unique perspective to compare the likely fracture-stimulation responses (and, notably, the potential differences in response) between wellbore stages. As a result, you’ll be equipped to pinpoint the locations where disparities in treatment response may be more probable.

Proactive planning. Post-frac diagnostics. StageStats analysis has it covered.

In addition to providing valuable precompletion insights for proactive planning, StageStats analysis gives you the ability to enhance post-fracture treatment diagnostics.