Seismos

Austin, Texas, United States

Seismos

!

Experts in real-time acoustic sensing for the detection of performance anomalies.

About Seismos

Across Energy & Cleantech, Seismos leads the category of predictive analytics with the only non-invasive, low cost, cloud-enabled data acquisition and insights platform that models both performance and troubleshooting in real time.

In Upstream, the Seismos MWF (Measurements While Fracturing) system is powered by a unique AI data platform with over 15,000 stages that are correlated with production and can predict the quality of a stage with high accuracy.

In Pipelines, the company has demonstrated the ability to locate faults without physical intervention, a feat which no other technology could match.

Seismos is based in Austin, TX, has over 100 customers, and has been featured at the front cover of numerous industry publications.

Description of Services

PRODUCTS:

1). SAFA™ (SEISMOS ACOUSTIC FRICTION ANALYSIS)

SURFACE MEASUREMENTS. DOWNHOLE PRECISION

Real-Time Friction Analysis for Optimal Well Performance

SAFA™ (Seismos Acoustic Friction Analysis) offers real-time, precise measurements of pipe and perforation friction, essential for optimizing hydraulic fracturing operations. This information helps operators improve their completions designs and automate the treatment, leading to better resource management and reduced operational expenses.

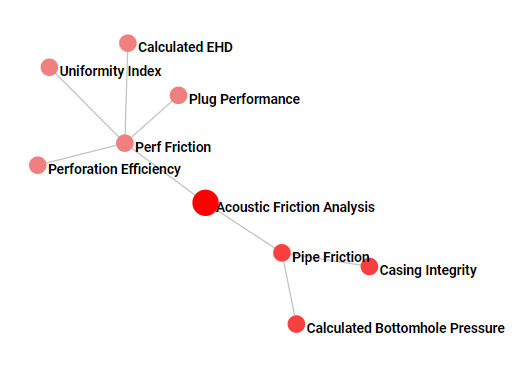

Acoustic Friction AnalysisPipe FrictionCalculated Bottomhole PressureCasing IntegrityPerf FrictionCalculated EHDPerforation EfficiencyUniformity IndexPlug Performance

REAL-TIME APPLICATIONS TO MAXIMIZE EFFICIENCY

OPTIMIZE PERFORATION SCHEMES, FLUID COMPOSITION, AND PUMPING STRATEGIES with real-time PERF EFFICIENCY

SAFA™ measures pipe and perforation friction in real-time to calculate perforation efficiency and advises to make precise adjustments to perforation schemes, fluid compositions, and pumping strategies. This optimizes performance, reduces costs, and improves overall efficiency for frac operations.

FINE-TUNE FRACTURING FLUID PROPERTIES USING SAFA™ generated PIPE FRICTION CURVES

SAFA™ generates pipe friction curves and bottomhole pressure data, allowing operators to evaluate FR concentration and the impact of water quality on FR performance in real-time. This ensures optimal fluid performance, maximizes efficiency, and minimizes friction-related issues during hydraulic fracturing treatments.

Track cluster flow DISTRIBUTION USING SEISMOS UNIFORMITY INDEX

SAFA™ uses multiple measures of perf efficiency throughout frac stimulation to monitor cluster flow distribution. By improving the average Uniformity Index (UI) by as little as 0.1 in a given well, first-year production can be increased by 2.5%.

QC perf gun performance by measuring INITIAL ENTRY HOLE DIAMETER

SAFA™ calculates EHD before perforation conditions start to alter due to erosion or other factors. Having the correct EHD is crucial for achieving the desired limited entry designs. Ensuring EHDs are within specification is the first step to creating a predictable and efficient fracture treatment.

2). MWF™ (Measurements While Fracturing)

What's MWF?

Real-time Quality Control Agent for Fracturing

Seismos MWF™ extends beyond fracture diagnostic technologies, displacing the need for fiber optics by introducing a plug-and-play system that seamlessly connects to the wellhead and uses acoustics and AI to continuously monitor each stage's stimulation performance.

Operational advantages:

- No need for fiber optics

- 1502 connection to wellhead

- Continuous monitoring behind the scenes

- Real-time prompts

Applications:

Can't improve what isn't measured

The Seismos MWF ™ (Measurements While Fracturing) Quality Control system embeds a one-of-a-kind measurement referred to as NFCI (Near Field Connectivity Index). NFCI is a patented measurement of the reciprocal of flow resistance (NFCI = 1/flow resistance) in the near wellbore area. The higher the NFCI, the higher the ability of the fracture network in the near field (near wellbore) area to allow hydrocarbon inflow into the wellbore.

- Maximize near wellbore stimulation

- Identify optimal/suboptimal connected fracture systems

- Understand far field fracture geometry

Influencers:

NFCI sensitivities to stimulation treatment, geology, and stress interactions

A critical advantage and differentiator of NFCI is the high sensitivity to critical parameters such as stimulation treatment, geology, stresses, and number of clusters taking fluid.

Below are some examples visualizing such differences:

- Active Clusters

NFCI reflects on the number of clusters taking fluid. A cross correlation to camera data (capturing cluster erosion) shows that as more clusters take fluid, NFCI values increase proportionally, indicating a better connection between the wellbore and the extended fracture system.

- Treatment

Varying stimulation design parameters (cluster design, perforation design, stage spacing, and so on) has a material effect on fracture system properties, and how such changes in fracture system properties are captured by the NFCI measurement.

- Geology

The following image demonstrates the NFCI's ability to reflect on fracture system differences caused by subtle geology changes across the lateral (in this case, a well transitions from the Upper Austin chalk to the Lower Austin chalk). Such geological changes (whether from stage to stage or from well to well) frequently result in distinctly different fracture system properties. NFCI indicates a much better connection between the wellbore and the extended reservoir with increased brittleness at the Upper Austin Chalk lateral section.

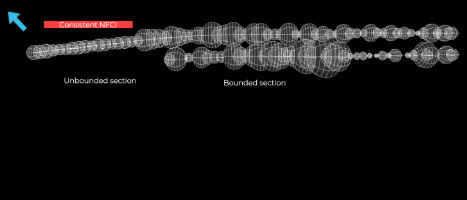

- Offset Stresses

The example below depicts the completion of a two-well zipper and the transition (for one of the two wells) from an unbounded to a bounded section. As the fracture systems approach each other - at the bounded section - NFCI demonstrates high sensitivity to fracture-driven interactions which is reflected on a consistent oscillating behavior of the NFCI values (as also visualized by the white spheres on the above visual). The proper sequencing of stimulation stages across the zipper can help reduce the overall stress interaction and ensure NFCI uniformity across both laterals.

Features:

Turning each well into a winner

Completions Optimization

- Establish maximum Near-Field Connectivity on a uniform stage-to-stage basis

- Adjust frac sequence to control stress interactions

- Establish sufficient connectivity to the reservoir

- Enable lateral stimulation consistency

- Test Designs

- Evaluate completion designs (perf/cluster, limited entry etc) that can ensure maximum Near Field Connectivity often leading to Cost Savings!

- Quality Assurance

- Ensure that all stages are significant contributors to production by monitoring completions performance in real-time

3). Ensure asset integrity with a non-intrusive technology

Discover a non-intrusive, cutting-edge technology for maintaining asset integrity like never before. Seismos-PPHM™ offers a versatile solution, assessing both piggable and nonpiggable pipelines, detecting disruptions in real-time. With applications for ad-hoc and continuous monitoring, it enables early prediction of potential failures, preventing costly economic and environmental consequences.

How it works:

Integrate Seismos-PPHM™ effortlessly through a simple surface connection, utilizing controlled acoustic signals to ensure a streamlined workflow. Benefits of Seismos-PPHM™:

- Enhance ILI program effectiveness while optimizing costs

- Proactively identify and address potential threats before they become hazardous and expensive

- Gain confidence inspecting challenging assets within and outside your facility.

Ad-hoc Monitoring:

Rapid Anomaly Detection at the Speed of Sound

Periodic controlled acoustic monitoring enables operators to swiftly detect and locate various pipeline anomalies. By adopting this cost-effective solution, you can reduce the necessity for manual inspections, minimize downtime, and prevent expensive emergency repairs. Say goodbye to unnecessary costs and hello to efficient pipeline maintenance.

- Corrosion

- Wall loss

- Deposits / Buildups

- ID Changes

- Stuck Pigs

- Deformations

- Hydrates

- Leaks / Breaches

Continuous Monitoring:

Early Disruption Detection & Prevention

Continuous or quasi-continuous acoustic monitoring empowers operators to detect anomalies at their earliest stages, accurately measuring their growth rate to prevent disruptive events. This invaluable insight allows operators to strategically allocate maintenance resources to critical sections and optimize scheduling for proactive interventions. Stay ahead of potential issues and safeguard your operations with Seismos continuous monitoring.

- Reduce Maintenance Costs

Detecting potential failures in advance, allows to prioritize maintenance more effectively. The technology also eliminate right-of-way access issues and optimize your maintenance efforts, ultimately lowering overall costs.

- Enhance Risk Mitigation

By intelligently allocating resources, inspection costs can be reduced without pipeline reliability being compromised. PPHM™ also optimizes pig run frequency, ensuring efficient and effective maintenance practices.

- Streamline Operations

PPHM™ provides enhanced compliance with greater risk assurance while lowering costs. You can ensure compliance requirements are met efficiently by continuously monitoring your assets, reducing the costs associated with manual inspections.

Versatile Applications:

Unmatched technology for widespread deployment across various industries

Seismos-PPHM™ boasts unmatched versatility, making it ideal for deployment across various industries reliant on pipeline transportation. With its continuous or ad-hoc monitoring capabilities, it caters to gas, water, CO2, crude oil, and hazardous fluid pipelines. Embrace this innovative solution to enhance safety, optimize operations, and significantly reduce maintenance costs, regardless of your industry.

- Oil and Gas

- Mining

- Hydrogen

- Facility

- Offshore and Subsea

- Water

4). MWF-Geothermal™

What's MWF-Geothermal™

Every challenge requires innovation and out of the box thinking.

While there are numerous challenges in geothermal projects, one of the main goals is to improve flow to the surface and increase surface area exposure to fluid. The use of various stimulation methods is one of the primary means of achieving these objectives in plan for the geothermal energy future.

Whether it's a hydrothermal resource or an enhanced geothermal system, using stimulation methods in geothermal prospects has had sporadic success in various projects around the world. Yet, there is hunger for innovation and project efficiency in terms of technical and economic aspects.

Most operators have traditionally completed geothermal wells in open holes, but the industry has recently realized that a constraining stimulation approach and the ability to isolate between zones can bring a lot more success in improving stimulation effectiveness, ultimately improving a project's prospects

Multi stage stimulation

Learning and applying experiences from the oil and gas industry in multistage stimulation is and will continue to be a key driver of stimulation success in geothermal prospects. As mentioned in a recent JPT (Journal of Petroleum Technology) article on multistage geothermal stimulation, the use of shale technologies will be one of the most important factors in the success of geothermal stimulation projects.

Why Seismos?

The Seismos Near-Field Connectivity Index not only quantifies the near wellbore fracture communication but gives the ability to understand stage to stage flow contributions when coupled with the measurement outputs.

In a geothermal world where analogous stimulation approaches from the oil and gas industry are applied, the Seismos technology could help:

- Better understand stage to stage complexity – ultimately understanding flow dynamics of each stage

- Apply real time changes to volumes pumped if insufficient complexity is achieved – running multiple acoustic measurements to better understand downhole response of stimulated stage

- Understand far field interaction between injection and production wells with fracture geometry outputs

- Apply the technology in any kind of pressure to temperature scenario considering that the application is noninvasive to the wells and is not dependent on pressure/temperature limitations