Clampon, Inc

Houston, Texas, United States

Clampon, Inc

!

ClampOn has manufactured non-intrusive sensors for topside and subsea applications for 30 years. Ultrasonic intelligent sensors.

About Clampon, Inc

Uncomplicated technology, modular design, easy installation and little or no calibration are keywords describing our range of instruments. This range includes sand monitors, PIG detectors, vibration monitors, leak monitors, condition monitors, well collision detectors, flow temperature monitor and corrosion-erosion monitors – all non-intrusive.

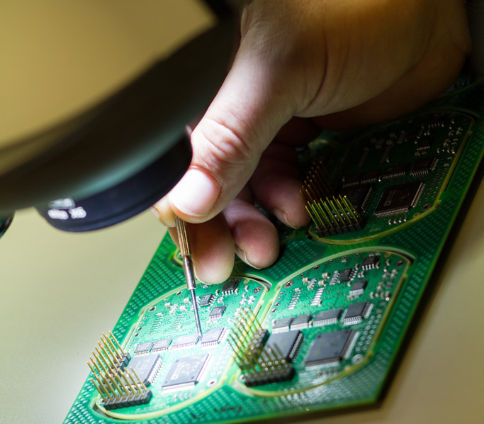

ClampOn’s basic philosophy is to develop, produce and sell top quality instrument solutions based on intelligent ultrasonic sensors (our core technology) and to offer services based on the use of these.

The advantages of focusing on one core technology are many:

- Simplification of production and stock holding

- A small number of competent suppliers

- Easier personnel allocation and project planning

- Sharper focus on rapid development of technology

- Core technology can be used in several applications

- Focus on market trends and development

In addition to the production and market advantages, our staff is highly competent and we have a unique expertise on sand monitoring that we also use for our Sand Management customers.

Our approach

Our straightforward approach to design and installation means that our sensor systems can be commissioned by offshore personnel themselves, anywhere in the world, without factory supervision. However, to get the best possible results from your ClampOn equipment we recommend involving ClampOn when the instruments are first brought online. With several thousand instruments sold, ClampOn has become the market leader in sand, PIG and corrosion-erosion monitoring. This approach to the market has been very well received by our customers all over the world.

Leading-edge technology

Our leading-edge technology has made ClampOn capable and competitive in offering the products that customers are looking for. Our reference list is an expression of this. We regard sales to companies as Aker BP, ConocoPhillips, Chevron, Total, Equinor and Shell as vital proof that we offer instrumentation the market needs. Shell International has selected ClampOn as its principal supplier of sand monitoring systems after extensive testing of all available systems in the market. We are still (after more than 30 years) a growing company, our personnel have extensive experience in the petroleum industry and we offer first-class expertise in this sector. Since we started, we have grown to be the largest supplier of passive ultrasonic systems to the petroleum sector worldwide.

Description of Services

Services:

ClampOn services are well known. Our team of experienced and dedicated field engineers work hard to keep all these systems, many of them in extremely remote places, operational.

-

Support and Service

Sand monitoring - more than just sensor selection. Sand monitoring can be a time-consuming process that requires experience, so using the operator’s own personnel can be expensive. Continuity is also important, and frequent changes of personnel make it difficult to maintain the necessary continuity and experience. However, installing and using ClampOn acoustic sand detectors on a well-designed and well-maintained system is not complicated.

-

Field service

Sand or Erosion monitoring, PIG detection or Leak detection. In spite of all the communication solutions available, some work must be done in the field. It is important for ClampOn to know our customers. Every day of the year ClampOn engineers are in the oil and gas fields, working with Sand or Erosion monitoring, PIG detection or Leak detection. This is the best way to ensure that we can meet the high expectations of our customers.

-

Well test and rental

Rent the ClampOn equipment you need. In many cases a rental system is the right solution. Rental is a more flexible solution. The right equipment in sufficient quantity and with the right type of support can be mobilized within a very short time. For a standard one channel system our delivery time is one work day.

What we do

Products:

-

BIRD Condition Monitor

The ClampOn BIRD Condition Monitor is a new and unique wireless acoustic sensor for the downstream and unconventional market. The BIRD (Battery-operated Intelligent Remote Detector) is non-intrusive and can be used for various types of condition monitoring of pipes, flowlines, valves and other structures.

-

Subsea Flow Temperature Monitor

The ClampOn Subsea Flow Temperature Monitor is a non-intrusive sensor that calculates and monitors the temperature of the flow medium from outside the pipe.

The ClampOn Subsea Flow Temperature Monitor can be used as a standalone temperature sensor. The instrument can be retrofitted to existing installations, for example to replace broken intrusive sensors. It can also be integrated into ClampOn’s range of Compact Subsea sensors to provide temperature measurement alongside sand monitoring, pig detection, vibration monitoring or leak detection.

-

Subsea PIG Detector

PIG detection made easy and reliable.

The Non-intrusive ClampOn DSP PIG Detector detects and monitors when the PIG is passing the point of installation. Providing reliable information about the passage of the PIG increases pipeline integrity and produces cost savings.

-

Particle Monitor

Any owner or operator of a factory would surely like to operate it as efficiently and profitably as possible. An oil or gas well can be regarded as a factory, and the ClampOn sand detector gives operators the best tool for maximizing profits. ClampOn’s DSP systems operate on thousands of wells every year, and the company is the world’s largest supplier of sand monitoring systems. ClampOn is the natural choice for sand monitoring and management programs!

-

Corrosion-Erosion Monitor

The patented ClampOn non-intrusive Corrosion-Erosion Monitor (CEM) has been designed to monitor the average wall thickness of pipes, containers and any large object that requires corrosion/erosion monitoring. The ClampOn CEM system utilizes a unique method of monitoring wall thickness loss by the use of clamp-on sensors. A number of transducers measure corrosion-erosion by transmitting ultrasonic signals that propagate through pipe material. Using ClampOn acoustic transducers means that no drilling or welding that would cause loss of production is required.

-

PIG Detector

The ClampOn DSP PIG Detector registers and monitors when the PIG is passing the point of installation. Providing reliable information about the passage of the PIG increases pipeline integrity and produces cost savings.

-

Subsea Particle Monitor

The ClampOn Subsea Particle Monitor is a non-intrusive sensor that detects and monitors sand in the production line.

Sand production in Oil and Gas wells is one of the most challenging factors an operator faces during production. Going subsea, safety issues in conjunction with the need to produce as much as possible per well, makes the selection of a subsea monitoring system even more important.

-

Subsea Corrosion-Erosion Monitor

The ClampOn Subsea Corrosion-Erosion Monitor (CEM) continually monitors and quantifies changes in wall thickness over a large area of a pipeline. The non-intrusive instrument estimates the rate at which corrosion and/or erosion reduces the thickness of the pipe wall. In this way, it can provide operators with an early warning of potentially catastrophic failures before they occur. The CEM is therefore also an effective tool in helping operators comply with newer regulations regarding the need for condition monitoring. It can be retrofitted to existing structures or installed on new pipelines before they are deployed subsea.

-

Subsea Vibration Monitor

ClampOn Non-intrusive sensors for Subsea Vibration Monitoring.

Vibrations always start at very high frequencies and change to lower frequencies as the conditions develop. The ClampOn DSP Vibration Monitor is an ideal instrument to monitor three directional vibrations on structures and pipelines with either high frequency shear waves or low frequencies. The Vibration Monitor is designed with a broadband frequency from 0 Hz to 1000 Hz in terms of 3D vibration, at the same time as ultrasound noise can be monitored up to several hundred kHz. Solutions are available for early detection of vibrations in objects such as:

- Flow lines, jumpers

- Pumps, rotary machinery

- Subsea structures

-

Subsea Condition Monitor

ClampOn DSP Spectrum Analyzer.

The Spectrum Analyzer digitizes the ultrasound from 20 to 1000 KHz, performs frequency analysis in real-time and sends the spectrum digitally to a PC where application specific algorithms can be applied and the results stored and presented.

This makes the Spectrum Analyzer a compact condition supervisor that can alert the user to cracks, corrosion and vibration in a range of different applications, from pipelines to rotating machinery, chokes, valves etc.

The Analyzer utilizes non-intrusive ultrasonic technology; the tool is attached (clamped on) to the outside of the structure it is to monitor.

-

Subsea Leak Monitor

The Non-intrusive ClampOn DSP Leak Monitor detects small and medium leaks or flow-throughs, even with low differential pressure over the measuring point on pipes and valves. The ClampOn DSP Leak Monitor has been developed with the aim of offering a product that can quantify a leak through a closed valve. The ClampOn DSP Leak Monitor is qualified as a subsea and topside monitor.

-

Well Collision Detector

The ClampOn DSP Well Collision Detector is designed to prevent collisions involving directional drilling within the proximity of existing wells. ClampOn DSP Well Collision Detectors provide operators with real time data so that collision risk analysis calculations are not the only factor determining the bit’s proximity to existing wells.

This method uses ClampOn non‐invasive ultrasonic sensor technology in the form of a spectrum analyzer. The spectrum analyzer digitizes the ultrasound allowing frequency analysis in real‐time.

-

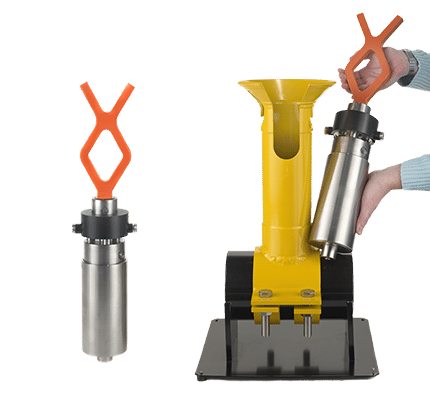

Subsea Retrofit Solutions

ClampOn offers various retrofit funnel solutions / clamp solutions.

High Flexibility

- Non-intrusive (cost-effective installation)

- ROV Retrofit

- Diver Installable

- Designed for 3000 meters depth

- Battery pack & internal logging

- Multifunctional (Sand, PIG, vibration etc.)

-

Vibration Monitor

Vibrations always start at very high frequencies and change to lower frequencies as the condition develops. The ClampOn DSP Vibration Monitor is an ideal instrument to monitor vibrations in 3D on structures and pipelines. The system is designed with a broadband frequency response from 0,125 Hz to 262 kHz, suitable for early detection of vibrations in objects such as:

- Flow lines, jumpers

- Pumps, rotary machinery

- Slugs etc.

-

Leak Monitor

The ClampOn DSP Leak Monitor detects small and medium leaks or flow-throughs, even with low differential pressure over the measuring point on pipes and valves. The ClampOn DSP Leak Monitor has been developed with the aim of offering a product that can quantify a leak through a closed valve. The ClampOn DSP Leak Monitor is qualified as a subsea and topside monitor.

-

Condition Monitor

ClampOn DSP Spectrum Analyzer

The Spectrum Analyzer digitizes the ultrasound from 20 to 1000 KHz, performs frequency analysis in real-time and sends the spectrum digitally to a PC where application specific algorithms can be applied and the results stored and presented.

-

Service Tools

- ClampOn sensor browser:

Use this software service tool to discover, test, reconfigure or download new firmware to ClampOn Sand, PIG, leak or vibration monitors with a serial Modbus interface. The tool also offers a simple trending function, allowing you to use it for short-term monitoring tasks.

- ClampOn Serial Tool:

When troubleshooting serial communication through in-built COM-ports, serial port servers (virtual port or raw TCP socket) or other TCP ports, it is often useful to see the data traffic and be able to define and send sequences or repetitions of test commands. In addition to the useful command function this generic software service tool also offers multiple ways of displaying the data (ASCII/hex/code – with or without time stamping) and has a command studio function that helps you generate valid Modbus commands (or more specific to ClampOn; valid DSP commands). If you need help with or are troubleshooting a ClampOn system this tool might help by documenting the data communication and/or sending commands to the equipment.

- ClampOn DSP2 PIG Configuration Tool:

This service tool allows you to test and/or change the detection, alarm, 4-20 mA and relay settings of your DSP2 PIG detector. You can also start or stop the internal logging in the sensor and retrieve the historical data. If there is a problem with the device, the trend, internal logging and communication log from this tool can help us resolve the issue.

-

Modbus Test Master

Modbus Test Master makes it simple to set up, document and test complex Modbus systems.

Create device profiles and specifications, pick and choose registers freely

- Define multiple data types

- Specify units

- Add scaling and comments

Add as many instances of the devices you have to as many RTU, ASCII or TCP channels as you need. Prefer to see trends of one or multiple sets of values while testing? Or want the data traffic explained while troubleshooting? Modbus Test Master makes it easy.

Advantages

- Device profiles and specifications make it easy to build, document and demonstrate the test system

- Trends and register lists allow you to test and document device behaviour and performance

- Communication logs with filtering, highlighting and comments help you troubleshoot issues for individual channels and devices

- CAN Monitor

Whether you are a control system vendor, system developer or service personnel, ClampOn CAN Monitor, combined with a CAN interface from National Instruments, provides you with a powerful generic test and monitoring solution for your CAN/SIIS Level 2 instruments of any make (not just from ClampOn).

Advantages

The software lets you configure your network and devices using NMT and LSS, and access the object dictionary using Electronic Data Sheet (EDS) files. You can read and write PDOs and SDOs, either manually, continuously (with trending), or as part of a test script.

We developed this tool to replace and improve upon other dominating tools on the market, like Ixxat Device Manager and Vector CANalayzer. With added support for features from SIIS Level 2 / CiA-443, CAN Monitor is a catch if you work with subsea instrumentation. If you already have a CAN interface from NI, or would like to buy one.

Life at Clampon, Inc

User-friendly & cost-effective products

Focusing on our core technology has enabled us to sell user-friendly, cost-effective products to customers all over the world. We are represented in all major regions that are vital to the petroleum industry. Even though our headquarters and production line are located in Norway very close to the North Sea, 85% of our sensors are exported to every continent.