Cleanwater1

Vineland, New Jersey, United States

Cleanwater1

!

Your Solution for Water Quality and Wastewater Treatment Just Got Better.

About Cleanwater1

cleanwater1 is a leading provider of water quality solutions and the only to offer a complete set of end-to-end water quality and wastewater treatment products and solutions.

cleanwater1 is dedicated to helping organizations exceed US clean water regulations and to ensure safe, reliable, low cost, high-quality drinking water and purified wastewater solutions.

cleanwater1 pairs proven brands like Polyblend®, Dynablend™, VeloBlend™, HydraMax™, Barracuda™, Mako™, I-BOx®, A-758 Lime Slaker, PAX Mixers, Monoclor® RCS and Microclor®, with cutting edge strategies and innovations to help customers meet and exceed water quality goals and regulations.

cleanwater1 prioritizes public health, environmental protection and financial savings for the well-being of our customers and their communities.

cleanwater1 is headquartered in Milpitas, California.

Description of Services

The Companies That Make Up cleanwater1

UGSI Chemical Feed

UGSI Chemical Feed pioneered the development of cost-effective polymer activation technologies for water and wastewater application. Notable brands include Polyblend®, Dynablend™ and Encore®

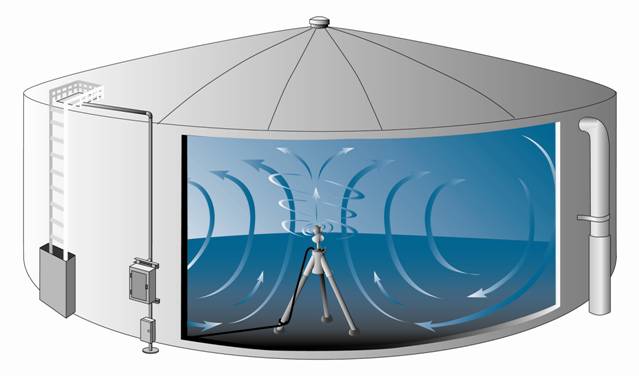

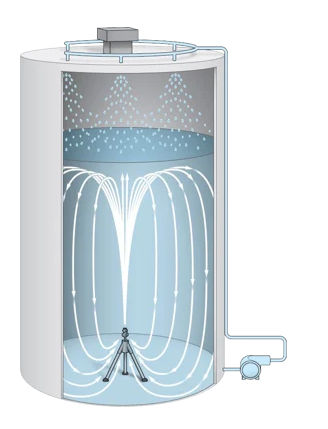

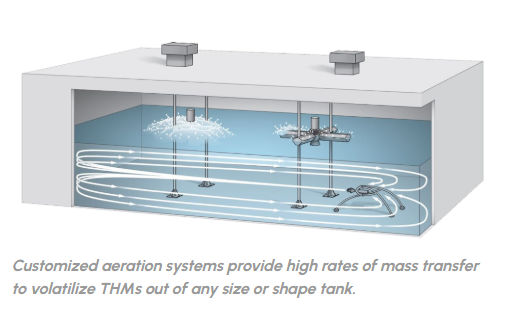

PAX Water

PAX Water Technologies was founded in 2006 to develop and market energy-efficient mixing systems for potable water storage tanks.

Inspired by nature and backed by science, PAX Water Technologies deliver innovative water quality solutions to safeguard drinking water for municipalities and the communities they serve.

PSI Water

PSI Water Technologies was the leader in OSHG generated hypochlorite solutions.

VeloDyne Systems

from environmental systems to bulk solids handling, Velodyne Systems has a solution for your process.

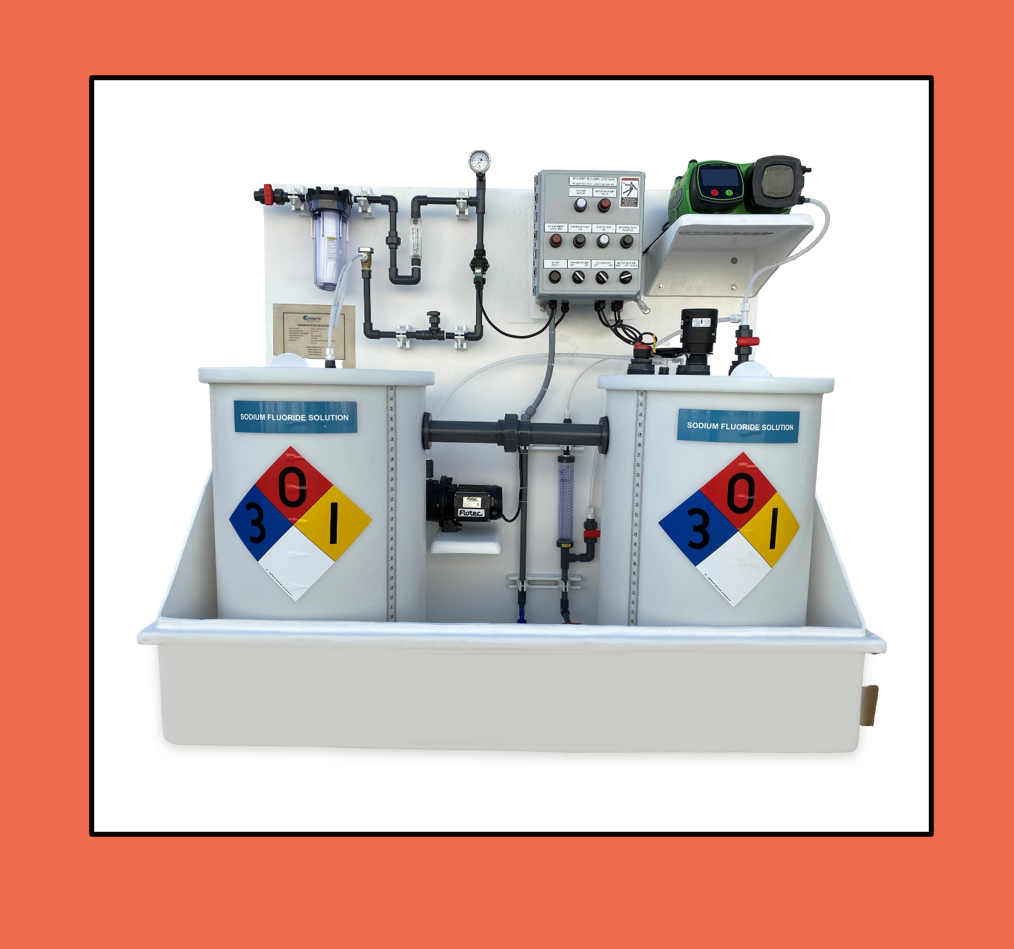

Integrity Municipal Systems

An engineering company devoted to designing and supplying innovative, pre-assembled, process solutions for the water and wastewater industry. Both standard and custom designs are offered. Complete functioning systems are designed with the user in mind, incorporating the latest technology and highest quality components.

What we do

OUR MISSION

Our mission is to provide innovative solutions that enable utilities to deliver safe and consistent water to the communities they serve and the environments they protect.

cleanwater1 is a leading provider of water quality solutions and the only to offer a complete set of end-to-end water quality and wastewater treatment products and solutions.

Products:

- On-Site Hypochlorite Generation

- Mixing

- Dosing Management

- Tank Venting

- Liquid Polymer Activation

- Dry Polymer Activation

- Chemical Metering

- Flow Metering

- Dry Chemical Feed Equipment and Control

- Silo Systems

- Optical Sensors

- Bag Systems

- Conveyors

- Lime Systems

- Integrated Control Capabilities

Life at Cleanwater1

Solutions

Wastewater Treatment

Three Proven Methods for Treating Wastewater

cleanwater1 is a leading provider of water quality solutions and the only to offer a complete set of end-to-end water quality and wastewater treatment products and solutions.

cleanwater1 pairs proven brands like Polyblend®, VeloBlend™, Mako™, Barracuda™, HydraMax™, Dynablend™, PAX Mixers, Monoclor® RCS and Microclor®, with cutting edge strategies and innovations to help customers meet and exceed wastewater goals and regulations.

Our three proven methods for treating wastewater are disinfection, solids thickening and dewatering and chemical feed.

Cleanwater1 Presents our Webinar: Systems for Handling, Feeding, and Delivering Bulk Solids in Small and Large Bags

This webinar will provide an in-depth review of the equipment used to handle and dose a variety of chemicals that are commonly used in their treatment processes and are delivered in 50 pound bags and 2,000 pound SuperSacks.

- Disinfection

Disinfection is the process of killing or inactivating microorganisms. Disinfection is typically achieved through the use of chemical disinfectants, such as chlorine, chloramine, or ozone. Disinfection is especially critical in areas where the water source is surface water, such as lakes or rivers, as these sources can be more vulnerable to contamination.

Effective disinfection requires careful management and monitoring to ensure that the appropriate levels of disinfectant are present in the water supply. The goal is to provide protection against waterborne diseases while minimizing the risk of harmful byproducts or other adverse effects.

On-site hypochlorite generation (OSHG) systems for disinfection have seen an increased adoption rate in the last decade as water and wastewater utilities continue to grapple with the onerous complexity of risk management plans (RMPs) in the case of gas chlorine disinfection and the operational or cost challenges of using bulk 12.5% sodium hypochlorite for disinfection. The latest generation of OSHG systems have been designed to emphasize safety, reliability and maintainability.

Disinfection is an essential aspect of water quality management that helps to protect public health and ensure that drinking water is safe and healthy for consumption.

- Solids Thickening and Dewatering

Applying polymer prior to a thickening or dewatering process is also called “conditioning”. Conditioning with polymer is often a requirement for the thickening or dewatering equipment to successfully operate.

Polymers that have a positive charge (otherwise known as cationic) and a high molecular weight are typically used for thickening and dewatering solids separation processes.

Different solids thickening and dewatering equipment and applications require different polymer/sludge mixing mechanisms. Some perform better when the polymer solution is injected in the upstream piping of the thickening or dewatering unit.

- Chemical Feed

Wastewater from households, industries, or commercial settings, contain various types of contaminants that can be harmful to human health and the environment if not treated properly. Chemical feed is used in wastewater treatment to remove contaminants from the wastewater and to purify it. Chemicals used in the wastewater treatment process include coagulants, flocculants, pH adjusters, and disinfectants, among others.

By forming larger particles, or flocs, these chemicals make it easier to separate the solids from the liquids. Once the solids have been removed, disinfectants are added to kill any remaining bacteria and viruses before the treated wastewater is discharged back into the environment.

Effective chemical feed in wastewater treatment requires careful management and monitoring to ensure that the appropriate chemicals are added in the correct dosage to achieve the desired treatment objectives. The treatment process may vary depending on the specific contaminants present in the wastewater and the treatment goals.

Chemical feed helps to ensure that wastewater is treated properly and safely before it is released back into the environment. The process requires careful management and monitoring to ensure that the chemicals used are effective in achieving the desired treatment objectives while minimizing any potential negative impacts on the environment.