DYNAMIC GREEN SOLUTIONS

Eureka, MO, United States

DYNAMIC GREEN SOLUTIONS

!

Optimizing Oilfield Operations, Preserving Well Integrity. International Leading-Edge Biodegradable Diverters.

About DYNAMIC GREEN SOLUTIONS

Optimizing Oilfield Operations, Preserving Well Integrity. International Leading-Edge Biodegradable Diverters.

DGS diverters help operators increase production while protecting offset wells.

Description of Services

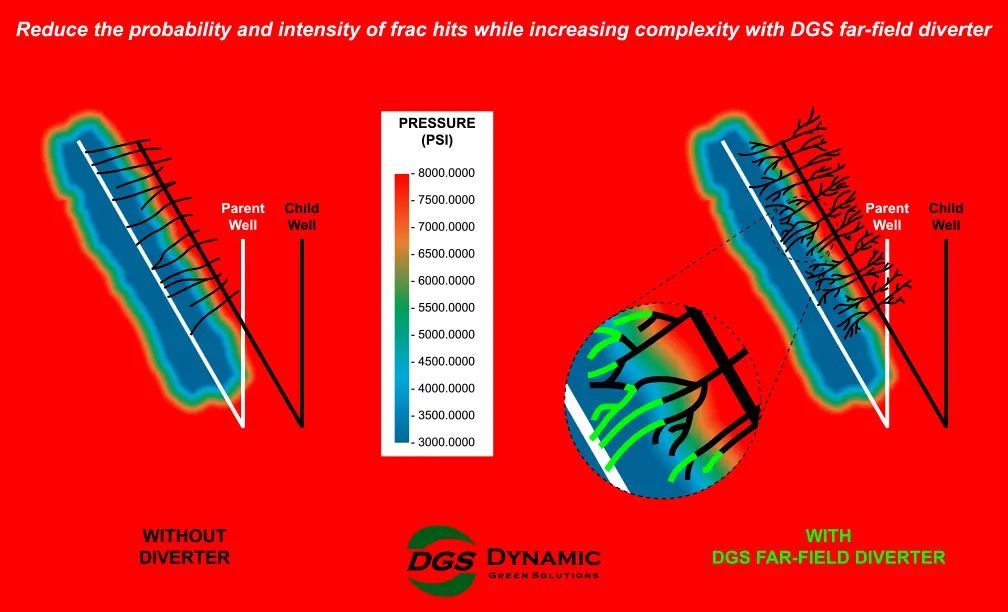

1). DGS Diverters for Far‑Field Diversion‑Fracturing

DGS diverters can help your well's production. Far‑field diverters, such as powders, increase production and reduce communication when used while fracturing.

As well spacing has been reduced the need to moderate fracture lengths has become increasingly important. Our far-field diverters are designed to keep fractures from extending further than ideal, instead a more complex fracture network can be developed.

The benefits of using our far-field diverters follow:

- Reduce the magnitude and probability of offset well communication.

- Increase the time to first communication

- Increased production by creating additional fracture complexity

- Slower decline curves

- Reduced fluid volumes are possible.

- DGS’s far-field diverters are available in various powders and flake such as our DGS Divert HCD, DGS Divert FF & DGS Divert SF009.

2). DGS Diverters for Near‑Wellbore Diversion‑Fracturing

DGS diverters can help your well's production. Near‑wellbore diverters, such as flakes, beads and course mesh powders can increase production when used while fracturing.

As wells are stimulated the fluids take the path of least resistance. Often this creates “super clusters” and fails to evenly treat the entire interval leaving many clusters untreated or under treated. DGS Diverters work to temporarily block the most active clusters allowing new clusters to initiate or increase the level of treatment.

Other techniques of controlling these runaway fractures help but they never can create as balanced of a treatment as diverters and they also fail to address communication between stages behind pipe which is estimated to occur in 30% of stages based on tracer logs.

The benefits of using our near wellbore diverters follow:

- Increase cluster efficiency.

- Allow operators to fracture dissimilar rock

- Allow operators to fracture large sections of open-hole allowing them to drill beyond their ability to run casing.

- Stage counts can be reduced by completing longer intervals.

- In situations with damaged casings several stages can be completed as one stage.

- Production is increased by creating additional fractures.

- Communication is reduced because “super cluster” fracture lengths are controlled.

- Communication between stages can be eliminated.

- DGS’s near wellbore diverters are available in bead, flake and powders such as our DGS Divert NWB FB & DGS Divert F015.

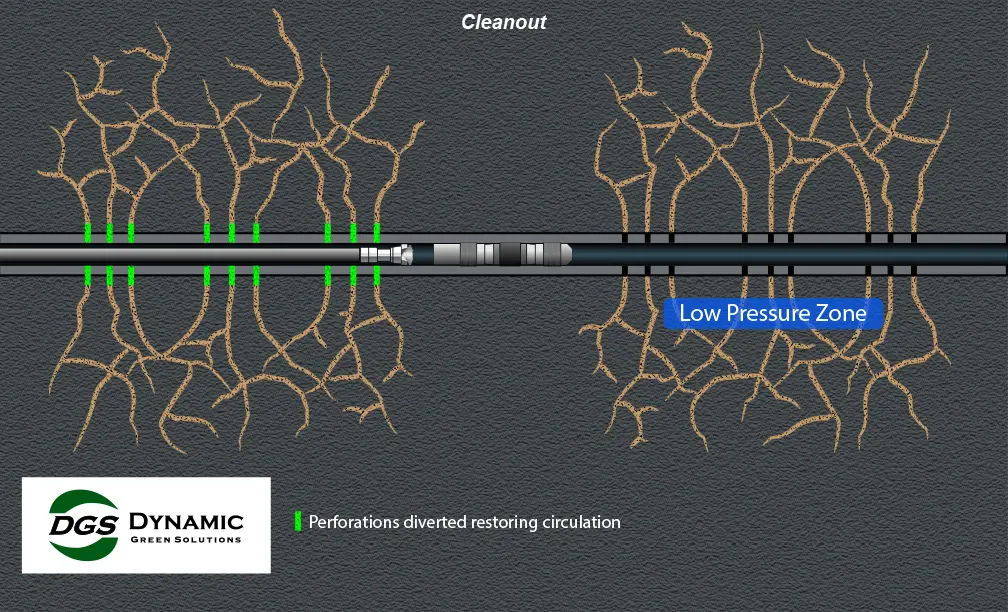

3). Cleanouts/Milling Operations

DGS diverters can help regain circulation in low-pressure wells.

As operators are attempting to circulate fluids to mill plugs or cleanout low pressure wells sometimes there are insufficient returns to surface to adequately remove all debris and plug parts. DGS Diverters work to temporarily block perforations and effectively restore returns to surface.

The benefits of using our LCM materials follow:

- Additional plug parts and proppant can be removed from the wellbore with the turbulent flow our diverters help create.

- Reduce the chances of sticking pipe.

- DGS Divert C is designed to work with both workover rigs and coil tubing units.

- DGS Diverters lower specific gravity helps place the diverter, even when reverse circulating.

- Remedial work can be performed once returns are established.

- DGS’s cleanout diverters are available in bead, flake, and powders such as our DGS Divert C & DGS Divert SF009.

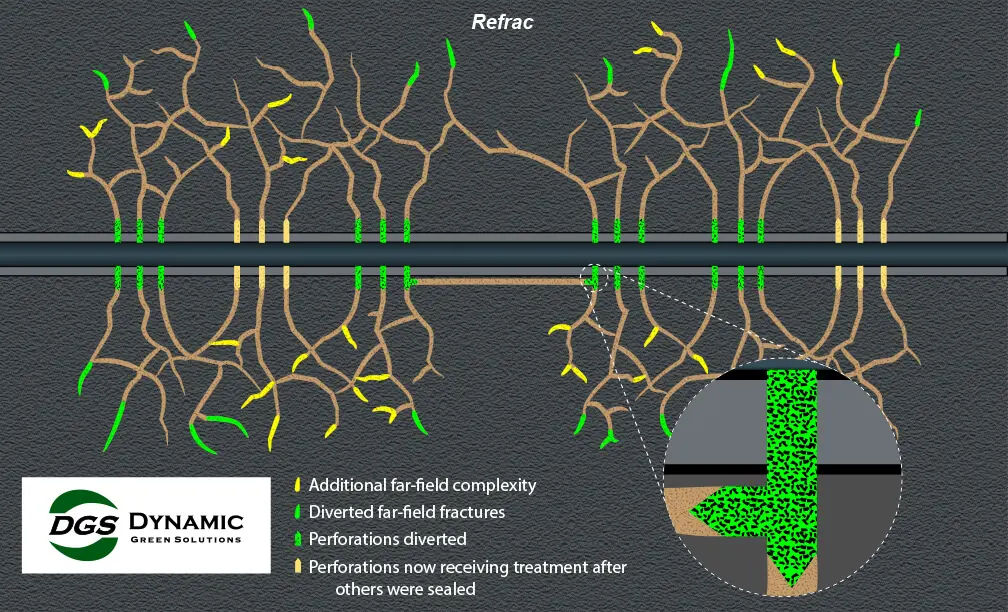

4). Recompletions

DGS diverters can help bring your older/depleted wells back to their full potential.

DGS Divert forRefracturing

As wells are stimulated the fluids take the path of least resistance. Often this creates “super clusters” and fails to evenly treat the entire interval leaving many clusters untreated or under treated. DGS Diverters work to temporarily block the most active clusters allowing new clusters to initiate or increase the level of treatment.

Additionally, fractures can be further controlled with far-field diverters, creating complex fractures as opposed to lengthening fractures.

The benefits of using our diverters follow:

- Increase production by creating additional fracture complexity

- Increase production by creating additional fractures.

- Stimulate new rock and reduce the occurrence of offset well frac hits

- Fracture dissimilar rock

- Can help increase production by creating additional fractures.

- Can be used to screen out old perforations to run new perforations.

- DGS Divert will self-remove in the presence of water and heat after treatment is finished.

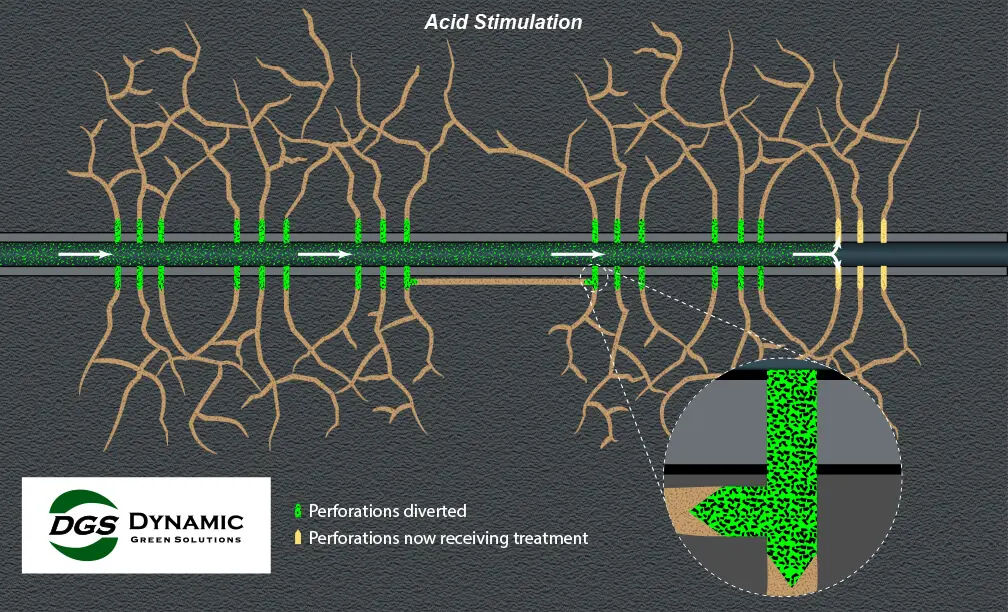

5). Acidizing

DGS diverters can improve fluid distributions to make acid treatments much more effective.

Improving Oil Well ProductivityThrough Acid Treatment

As wells are stimulated the fluids take the path of least resistance which results in most acid treatments only treating the heel of a well and often leaves the majority of the well untreated or under treated. DGS Diverters work to temporarily block the perforations taking fluids forcing the treatment to additional perforations.

The benefits of using our acidizing diverters follow:

- Acid treatments are able to reach the entire interval

- Lower rate treatments are still able to divert fluid to untreated areas.

- When hydrolysis occurs a weak acid is created to further treat the well.

- DGS’s acidizing diverters are available in flake geometries such as DGS Divert SF009 and DGS Divert F015.

6). Drilling Fluid Diverters

DGS divert for Drilling Fluid Diverters.

DGS Divert forDrilling fluid diverters

As operators are attempting to circulate fluids to drill wells low pressure reservoirs sometimes provide insufficient returns to surface. DGS Diverters work to temporarily block high permeability rock and fractures.

The benefits of using our LCM materials follow:

- Additional drilling debris can be removed from the wellbore.

- Reduce formation damage.

- Reduce cost of drilling fluids.

7). Geothermal Diverters

DGS divert for Geothermal Diverters.

Geothermal wells offer a whole different set of challenges. Not only does the additional heat often require unique chemistries it also requires extra care so as to not damage the reservoir.

DGS diverters are engineered to meet these requirements.

The benefits of using our diverters follow:

- LCM materials can be used preventing significant amounts of fluid losses while drilling.

- Can help increase production well results by creating additional fractures.

- Can help increase production well results by creating additional fracture complexity.

- Temporary materials can be used before more presentiment materials to gauge performance increase.