E.H. Wachs

Lincolnshire, Illinois, United States

E.H. Wachs

!

Tools for the piping industry.

About E.H. Wachs

Since our founding in 1883, Wachs has enjoyed a rich history of equipment innovation and market leadership that has endured for nearly 140 years. The story of Wachs encompasses three centuries, four continents and four generations of the Wachs family.

The story begins in Europe, where a young Edward H. Wachs decided to emigrate from Germany to America. He began his career as an apprentice machinist in Ohio, before moving to Chicago, IL. In 1883 he founded a steam fitting firm that bore his initials and name - E.H. Wachs.

At first focused solely on steam fitting, after several years he recognized the need for a simple and reliable steam engine. E.H. Wachs designed and began manufacturing the Wachs Vertical Steam Engine, a single cylinder, double-acting vertical engine that ultimately would be manufactured in power ratings from 1 HP to 60 HP. The design of this steam engine proved so fundamentally sound that it would remain in constant production for the next 80 years.

1900 to 1950

As the new century dawned, Wachs diversified by manufacturing a line of coal mining machinery used in the sizing of coal for the Chicago firm of Roberts & Schaffer. Lasting for over 65 years, this established a pattern of building long term relationships that Wachs prides itself upon.

Business growth dictated another move in 1916 to a larger Chicago facility on Dayton Street, built to handle the needs of heavy machinery manufacturing. Branching out from steam engines and coal mining equipment, in 1917 Wachs designed and built a line of hand screw machines that firmly established the company in the machine tool industry.

The roaring 20s saw Wachs prosper, and by 1929 the company had grown to be one of the prime suppliers of machined components for sound movie projectors to the Western Electric Company. In the 1930's, as the Great Depression deepened, Wachs survived on jobbing work and machine repairs.

The conflict of the 1940s found the company engaged as a primary subcontractor to the Crane Company, involved in defense work for the Navy Valve Program. The contacts made during this period would propel the company in later years into valve related natural gas and water utility tools.

In 1944, Wachs purchased the valve division of National Machine Works, and with it their manufacturing and gas plant equipment line. The postwar years saw a dramatic upswing in gas equipment manufacturing, with vastly increased sales to Chicago area gas suppliers Peoples Gas and Northern Illinois Gas.

In 1949 came the invention that would revolutionize industrial piping procedures. Realizing the need to safely cut natural gas transmission lines without the torching (heat) process then common, Wachs perfected a unique, cold cutting pipe machine that minimized the danger of explosion. It stunned the pipe cutting industry with its breakthrough design, driving itself around the pipe while simultaneously cutting and beveling.

Utilizing a rotating milling cutter, it produced perfect weld preps in minutes. Called the Wachs Trav-L-Cutter, its the most versatile machine of its kind, and today is used in every corner of the globe. It offered field machinists unparalleled ease of setup, rugged reliability and the adaptability to handle most pipe and vessel diameters.

1950-1960

E.H. Wachs enjoyed phenomenal growth in the fifties. In 1953 Wachs developed another line of cold cutting machines, the ubiquitous Wachs Guillotine Pipe Saw. Responding to input from machinists in the field who demanded a rugged yet simple reciprocating saw for cold cutting industrial pipe, it avoided the pitfalls and dangers of torch cutting. Wachs Guillotine Saws remain the benchmark used around the world.

The increasing tensions of the Cold War found Wachs engaged in designing and producing machinery for Westinghouse Electric and the US Navy, in connection with the Nuclear Submarine Program. This partnership formed the foundation of our expertise in nuclear power, as Wachs branched out from this experience into machines designed and built for the nascent nuclear power plant industry.

From 1950 to 1958, the line of Wachs pipe cutting machines grew to include new market segments. Machines initially designed for the natural gas utility industry came to be widely accepted by the power generation industry, oil refineries, pipeline distribution, and water system operators and the contractors who served these industries.

In 1957 Wachs purchased the saw blade division of Illinois Tool Works. This acquisition allowed full control over production of our power saw blades, which would be nationally marketed under the Wachs Guillotine trademark. This purchase marked an important first step in the growth of Genuine Wachs blades and tooling, and our initial contact with the future ITW Corporation.

Responding to the needs of oil refineries, water system and pipeline operators among others, in 1958 Wachs developed and introduced a line of portable, handheld power operated valve turning machines. Today, this line includes handheld operators in three different drives for both rising and non-rising stem valves. Added later would be truck and trailer mounted valve operators with the power to handle large, industrial and water system valves, which would later grow into our Wachs Water Utility division.

1960-1970

As the fifties turned to the sixties, E.H. Wachs discontinued the manufacturing of steam engines and the supply of repair parts for these engines. In 82 years of manufacturing there were over 10,550 Wachs Steam Engines built, a testament to the inherent quality of its design and manufacturing excellence.

After exiting the steam engine business it was decided to discontinue outside jobbing work altogether, dedicating our staff and facilities exclusively to Wachs manufactured equipment. An equally important event occurred in 1966, when E.H. Wachs sold its building in the City of Chicago and moved to a new, larger facility in Wheeling, Illinois, a Chicago suburb.

1970-1980

In 1970, Wachs established a new entity called Power Cutting, Inc, or PCI. PCI was a joint sales and service company specializing in pipe cutting and machining services in the field using Wachs manufactured equipment. The PCI relationship allowed Wachs to benefit from the growing need for service cutting and in-situ machining in fossil and nuclear power plants, chemical plants and refineries. It led directly to additional product development, and an insider's knowledge of the industry's needs. The PCI division would later be sold to Westinghouse Electric Company.

The seventies would also see the expansion of E.H. Wachs into additional machines designed and built specifically for the water utility industry. In 1971 the Wachs Water Utility division designed, prototyped and tested the first TM series truck mounted valve operator, the TM-1. Introduced to serve the growing need in the water distribution industry for a high powered, portable and easy to use valve exerciser, it proved to be a highly successful, durable design.

It was the progenitor of our current microprocessor controlled TM-7 and ERV-750, available with our industry leading VITALS software. The Wachs Submersible Pump was developed at the same time to provide high capacity de-watering of valves vaults to assist in valve servicing and turning.

One year later, Wachs completed the development of a portable turning machine for rising stem valves. Now sold as the RS-2, this machine was introduced to offer the refining, petrochemical, chemical and pipeline industries a valve turning machine that could handle rising stem, hand-wheel activated valves.

In 1974, our PCI group had began researching portable lathes for its nuclear field services, after identifying a substantial market for this style machine tool. Learning from experience what changes would make for a more effcient tool, in 1977 Wachs introduced the new EP-1 End Prep Lathe.

Development of the concrete cylinder pile cut off saws began in 1968 when we built our first hand-fed saw in cooperation with Raymond International. The line was subsequently expanded to include three fully automatic cutoff systems. These were developed and field-tested at Raymond's Ju' Aymah trestle project in Saudi Arabia over a period of three years. In 1979 Wachs offered these cutoff systems for square concrete piles to the public, following two years of successful field testing.

The use of hydraulic power for our pipe cutting machines and pile cutting machines resulted in the development of a full line of hydraulic power units (HPU) to power these machines. Today the Wachs HPU line includes electric, gasoline, and diesel powered cart and skid mounted units with a wide range of horsepower and pressure ratings. In 1978 Wachs expanded the Wheeling plant to supply additional floor space for fabrication and assembly.

1980-2000

The early eighties saw a flurry of new product innovations. In 1982, the Model EP-2 End Prep Lathe was introduced following the success of the EP-1. The EP-2 offered improvements to address the need for a portable lathe with a larger machining capacity, greater accuracy and enhanced ease of use. This machine would further evolve into our rugged EP-3, designed specifically for large diameter heavy wall pipe.

Introduced at the same time was our SDB Small Diameter Beveler machine line. An ID mount machine, today its comprised of machines capable of end prepping .875" through 24" (22.2mm - 610mm) diameter pipe for the high-production end beveling market.

E.H. Wachs celebrated our centennial 100 years to the day on June 6, 1983. The Wachs Centennial also marked renewed investments in research and development that sought to ensure continued growth and stability for the next hundred years.

The nineties saw a rapid growth in sales, with an expanded presence in both Canada with Wachs Canada Ltd and in Europe with the founding of Wachs UK. The earlier research and development investments bore fruit with the introduction of a line of rotating cutters and bevelers that were designed to split in half for installation on inline pipe. These machines would set the industry standard for simultaneous inline cutting and beveling of tube and pipe.

These machines are known as "Split Frames" (or clamshells), and today Wachs offers a complete family of Split Frames including the Modular Design Split Frame (MDSF), the Large Diameter Split Frame (LDSF) for large diameters and vessels, and the Small Diameter Split Frame (SDSF). The SDSF series is ideal for working in close quarters, and is the foundation of our advanced socket weld removal and chipless wheel cutting modules.

2000 - Today

Following the millennium, it became apparent that the company was rapidly outgrowing its existing facility. In 2006 Wachs relocated to a new, larger facility in Lincolnshire, Illinois, approximately 20 minutes north of Chicago's O'Hare International Airport. Our headquarter facility houses our state of the art manufacturing area as well as the engineering, general administrative and sales offices for both domestic and international operations. Reflecting our manufacturing excellence we're ISO 9001-2015 certified, and E.H. Wachs was named one of the "Ten Best Machine Shops" by American Machinist magazine.

In 2007, Wachs opened the first of many Sales, Service and Rental facilities in Houston, Texas. Strategically located in Pasadena, TX it's centrally located to serve the nearby oil and gas activities. In 2008, Wachs celebrated 125 years in business with domestic and international expansions, with additional space dedicated to the manufacture of our expanded line of Wachs Water Utility equipment.

This includes custom manufactured valve maintenance trailer systems, plus skid and truck mounted maintenance systems, each designed to exercise and maintain water system assets to AWWA standards. Other tools include extended reach valve exercisers, hydraulic power units and vacuum excavation systems designed for the needs of water and natural gas distribution professionals.

The Wachs Water Utility division remains a pioneer in microprocessor control of the valve exercising process. The continued evolution of our VITALS software with Intelligent Automation offers true hands-free valve exercising, plus the ability to synchronize our smart handheld controller with the operator's network PC.

2008 also saw the addition of a second Wachs Canada Ltd Sales, Service and Rental Center in Edmonton, Alberta in addition to the Center in Newmarket, Ontario. In recent years we've added US Sales, Service and Rental Centers in the Northeast, Southeast, Southwest and West Coasts.

In 2009, after four generations of stewardship by the Wachs family, E.H. Wachs was acquired by the Glenview, Illinois based ITW Corporation, completing the relationship established with Illinois Tool Works 50 years earlier. Wachs joins other welding related companies such as Miller Electric and Hobart in ITW's Welding Group, further strengthening ITW's position as the industry leader in welding equipment technology.

Taking advantage of the resource base and global reach of ITW, we're confident our next 140 years will be as successful as our first 140 years. Built on a solid foundation of engineering and manufacturing excellence, we're dedicated to continuing the spirit of innovation and manufacturing excellence pioneered by Edward H. Wachs over a century ago. Today, building on our rich history of superb customer service and a dedicated and enthusiastic work force, we continue to design and build the best field portable machine tools and valve exercisers in the world.

Description of Services

a) Split Frame Pipe Cutters/Bevelers

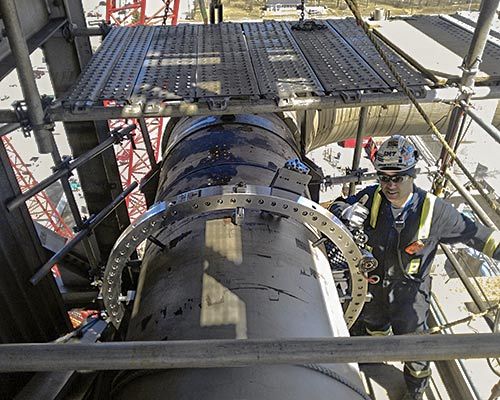

E.H. Wachs Split Frames are the world's most versatile and comprehensive line of clamshell style, field portable pipe cutting, and beveling machines on the market today. Designed to cut, bevel, single point, counterbore, and face flanges on pipe ranging from .5 to 120 inches O.D. (DN15-3000) on most wall thicknesses and materials, E.H.Wachs has a split frame to fit most pipes, tubes, or pressure vessel sizes.

Wachs Split Frames are offered in three size ranges:

- Wachs SDSF (Small Diameter Split Frames) for cutting, beveling, and counterboring pipe and tubing from .5 inch - 6-inches O.D. (DN15-150)

- DynaPrep MDSF Modular Design Split Frames. Our largest and most versatile portable pipe-cutting machine line's applications include cutting, beveling, facing, counterboring, and flange facing. Available in sixteen standard models for nominal pipe sizes ranging from 2in - 72in O.D. (DN50-1800).

- Wachs LDSF (Large Diameter Split Frame) is built for cutting, beveling, counterboring, and flange facing on pipes, valves, fittings, pressure vessels, and heat exchangers. The Wachs LDSF is available in four standard sizes, ranging from 60 inches to 120 inches O.D. (DN1500-DN3000).

What is a Split Frame?

Wachs Split Frames are named for their ability to split in half and mount around the outside of inline piping. They can also be used for pipe end weld preparation and flange facing where they slide over the end of a pipe or pressure vessel. All Wachs Split Frames are built to last a lifetime and engineered to apply precise, consistently square cuts and bevels ideal for welding from the first cut to the last.

Split Frame - A field-portable clamshell-style pipe cutting and beveling machine tool (lathe) that splits to mount to in-line pipes, tubes, and flanges. Structurally it features a fixed rigid frame or ring for support and mounting, and a rotating ring for attaching machining modules and tooling. Both rings split to allow the whole machine to clamp or hinge around a pipe, tube, or flange's outside diameter (O.D.), prior to machining. During the machining process, the machine tool modules attached to the rotating ring perform specific functions (cutting, beveling, resurfacing, facing, or counterboring), while the fixed, rigid frame the rotating ring travels around stays securely mounted to the pipe, tube, or flange.

Also known as: Clamshell, Ring Lathe, Pipe Cutter, Pipe Beveler, Pipe Cutting Machine

In regard to cutting applications, all DynaPrep pipe weld prep machine tools perform inline pipe cutting, can cut off pipe ends, and sever corroded and damaged pipe. A pipe cutter by nature, these pipe-cutting machines can also simultaneously cut and bevel inline pipe and perform work in pipeline applications with normal and heavy wall pipe. For heavy wall pipes, additional modules are available. Also, each machine can bevel inline pipe and bevel pipe ends and act as a pipe end prep beveling machine tool, and can chamfer inline pipe and bevel pipelines. In certain applications where a compound bevel is needed, the DynaPrep can act as a compound beveler, beveling with form tools or single-point machining complex preps such as j-prep bevels.

Moving beyond cut and bevel capability, each DynaPrep MDSF can be equipped with modules for flange facing which will convert the DynaPrep from a pipe cutter into a flange facer that can face and resurface flanges. As a flange resurfacing machine, the DynaPrep MDSF can perform smooth resurfacing, raised face resurfacing, record grooving, and RTJ ring groove creation and resurfacing.

When the need arises to counterbore pipe, the DynaPrep series of rotating lathe machine tools can be outfitted with counterbore modules, enabling counterboring and deep counterbore machining of pipe ends creating desired lands for welding.

b) Valve Maintenance Systems

Our Valve Maintenance Systems are designed with water delivery, water distribution, and operator safety in mind and are vital to any Valve Maintenance Program. Turning valves by hand can take a lot of effort, causing physical discomfort and unnecessary injury over time to members of a valve maintenance crew. Our valve maintenance trailers and skids feature powered valve operators that automatically exercise the valves using our VITALS software. This specially designed software works the valve back and forth, removing build-up, rehabilitating the valves, and extending their life. This system also improves the crew's productivity since they no longer turn valves by hand. VITALS can determine the size of the valve, the valve position, the valve turning direction, record the exact GPS location of the valve, and more.

Our valve maintenance systems are also designed to keep the valve crew out of traffic. The vacuums, pressure washers, and exercisers are all accessible from the curbside or rear of the units. Whether you choose a trailer, skid, or our purpose-built valve maintenance truck body, you’ll see noticeable improvements in your water system and your crew.

Valve Maintenance Programs

A valve maintenance program is vital for the security of the water delivery network. Knowing where valves are located and ensuring that they operate as designed and work during emergencies are essential to any municipality or water utility. Exercising valves regularly will extend their service life. In an emergency, having valves that work as expected can reduce water loss, minimize damage and flooding, and prevent customer disruption.

When deposits from water and iron form on a valve, it can make the valve difficult or impossible to operate with hand tools. If a valve hasn't been turned regularly, it can require replacement, making it a liability for the water delivery system. If a valve is stuck in the closed position, it can prevent water delivery when necessary. A stuck open valve can cause additional damage during a water main break or other emergencies.

For cleaner water and to prevent valves from sticking, Wachs, Valve Manufacturers, the AWWA & EPA all recommend a valve maintenance program where valves are operated on a set basis, depending on the size and volume of water flowing through the valve.

- Critical and transmission valves should be exercised often, while smaller valves should be operated on a less frequent schedule.

- If a valve is lost, it's no longer being exercised. If it fails, it can bring down part of the system, causing customer disruption, damage, flooding, and unnecessary expense. Keeping track of valves is vitally important.

- Valve boxes should be cleaned out to maintain access to the valve.

- To operate these valves, a gradually increasing rotational force should be applied to the operator nut in a back-and-forth motion to clean and free the valve stem and gate, breaking off and flushing obstructions and debris into the system.

- The following information should be recorded for each valve:

- number of turns a valve takes to operate

- the size of the valve

- the valve's close directionality (clockwise or counterclockwise)

- the type of valve (gate valve, butterfly valve, etc.)

- the location of the valve (in the street, next to the road, latitude/longitude, etc.). Also, sometimes valve boxes can be inadvertently covered by landscaping or paving. A lost valve can be as bad as a broken valve.

- the last position (open, closed, etc.) should be recorded. If a valve is found in a different position than it was left in, or if it requires a different number of turns, it could indicate a problem with the valve.

- Valve condition (does it function correctly, is it leaking, condition of the operator nut, etc.)

- Valve box condition (is it full of debris, is the lid missing, is the vault centered properly, is it paved over, etc.).

c) SpeedPrep Pipe Bevelers

Wachs SpeedPrep SDB line of small diameter bevelers have been engineered for fast, precise onsite facing, beveling, compound beveling and counterboring of light and heavy wall pipe, tube or casing. Proven workhorses, they set up quickly with a self centering mandrel and chuck assembly mounting to the pipe I.D. Three models are available to prep from .875in-12.75in (22.2mm-323.9mm) O.D.

Wachs SpeedPrep EP 424 with the advanced AutoPrep autofeed system is a precision I.D. mount end prep machine tool designed to bevel, compound bevel, J prep, face and counterbore pipe, fittings and valves. Utilizing the revolutionary AutoPrep mechanism that feeds simultaneously in the axial and radial planes, the SpeedPrep EP 424 is simple to use, even for an inexperienced operator. It is powerful enough to form tool from 4in to 16in (DN100-400) through Schedule 160, and will single point from 4in-24in (DN100-600) up to a 6.5in (165mm) wall thickness.