FEBUS

Cypress, Texas, United States

FEBUS

!

FEBUS Optics is the manufacturer of all your distributed fiber-optic solutions.

About FEBUS

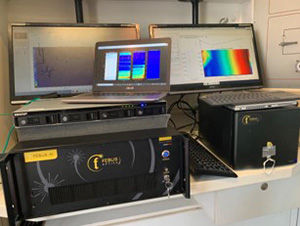

FEBUS Optics is the world reference in DFOS, distributed fiber optic sensing systems (DAS, DTS and DSS), to reduce the environmental impact of human activity, protect people, and optimize production.

FEBUS provides state-of-the-art devices and turnkey solutions based on its patented technologies, developed by its R&D department. Backed by its expertise, its highly qualified and experienced team, and its dedicated Test Center, FEBUS Optics combines excellence and reliability to meet the most complex challenges across various application fields.

Internationally established, FEBUS offers customized equipment and a wide range of worldwide on-site services, such as:

- cable monitoring,

- pipeline monitoring,

- monitoring of geothermal, CO2 or oil and gas wells,

- seismic acquisition,

- natural hazards monitoring,

- intrusion detection,

- structural health monitoring.

Description of Services

FEBUS Optics is the manufacturer of all your distributed fiber-optic solutions:

> Distributed Acoustic Sensing (DAS)

> Distributed Temperature Sensing (DTS)

> Distributed Strain Sensing (DSS)

Applications in oil & gas, geophysics, perimeter security, Marine Renewable Energy (MRE), geothermy and civil engineering are adressed by our products, available in rackable or compact form factor.

What we do

1). Cable Monitoring

- Reduction in maintenance costs

- Time savings during intervention

- Reduction of environmental impact

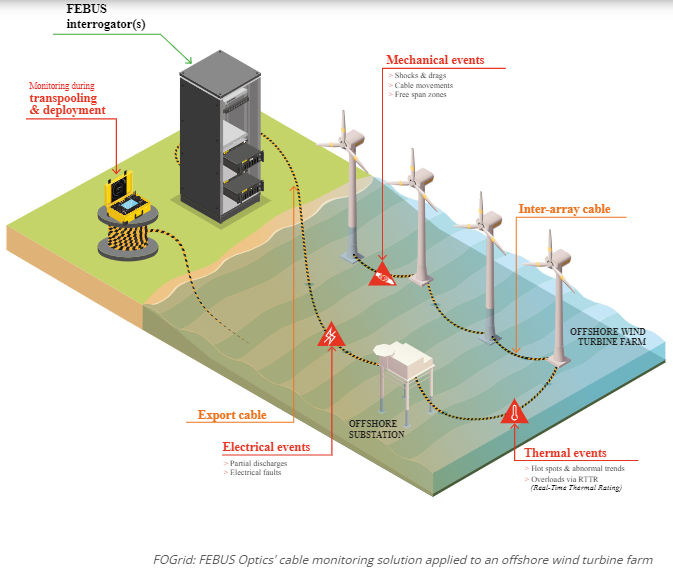

FOGrid is FEBUS Optics' solution for cable integrity monitoring. By combining our advanced distributed fiber optic sensing technologies and our software suite with dedicated algorithms, it enables to:

- monitor the proper functioning of overhead, buried, or submerged cables

- anticipate their failures

- provide a fast and appropriate response to detected issues

CABLE MONITORING USING DISTRIBUTED FIBER OPTIC SENSING

FOGrid is FEBUS Optics' comprehensive and easy to deploy solution to ensure a continuous real-time monitoring of the integrity of buried or overhead cables, whether offshore or onshore.

FEBUS' distributed fiber optic sensing devices use a single mode optical fiber already present in the cable. Based on reflectometry, FEBUS interrogators only need to be connected to one end of the fiber. This way, the deployment of our cable monitoring solution is simplified.

Our interrogators address long distances (several tens of kilometers) while providing spatially continuous measurements. By coupling with our REM (Range Extension Module), the range increases and investments are optimized as less interrogators are required for complete cable network coverage. Additionally, if a break occurs in the fiber length, measurements are taken up to the point of breakage.

Our devices FEBUS A1 (Rayleigh, DAS - Distributed Acoustic Sensing), and FEBUS G1-R (Brillouin, DTS - Distributed Temperature Sensing) provide with precise, reliable, and accurately localized data.

Continuous monitoring over the entire length of the cables is ensured.

- Thermal monitoring of the cable with the FEBUS G1-R

- Detection of any fault with the FEBUS A1

2). Pipeline Monitoring

- Prevention of environmental impact

- Reduction of human risks

- Increase in profitability

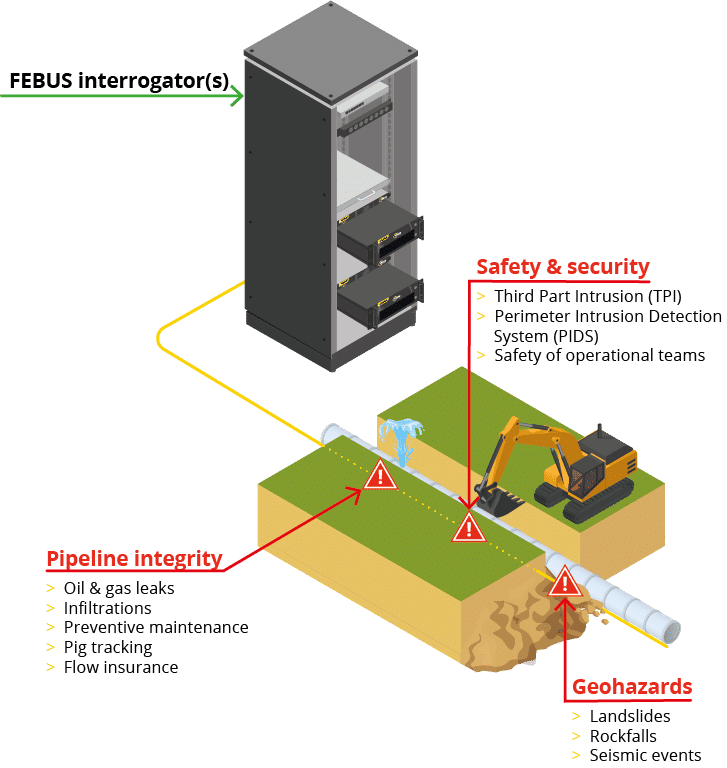

An onshore or offshore pipe spans tens or even hundreds of kilometers and can be exposed to numerous damages of human or natural origin. To detect these risks, define them and provide the most appropriate response, FEBUS Optics' solution enables continuous and end-to-end monitoring throughout the installation to:

- monitor the integrity of the pipeline

- anticipate, detect, locate, and identify threats and potential damages.

PIPELINE MONITORING USING DISTRIBUTED FIBER OPTIC SENSING

FOPipe is FEBUS Optics' comprehensive and easy to implement solution for ensuring continuous real-time monitoring of pipeline integrity, whether onshore or offshore.

Based on our various distributed fiber optic sensing patented technologies, it relies on the use of our interrogators:

- Distributed Acoustic Sensing (DAS, acoustic data) with the FEBUS A1

- Distributed Temperature and Strain Sensing (DTSS, temperature and strain data) through the FEBUS G1-R.

The combination of the performance of our measurement systems, our embedded software solution FOPipe Suite, and the power of our detection and classification algorithms allows:

- maximizing the availability and durability of infrastructure

- optimizing production and monitoring costs

- increasing the safety of operational teams

- preventing environmental risks.

3). Well Monitoring

- Production optimization

- Workover optimization

- Environmental and human risks reduction

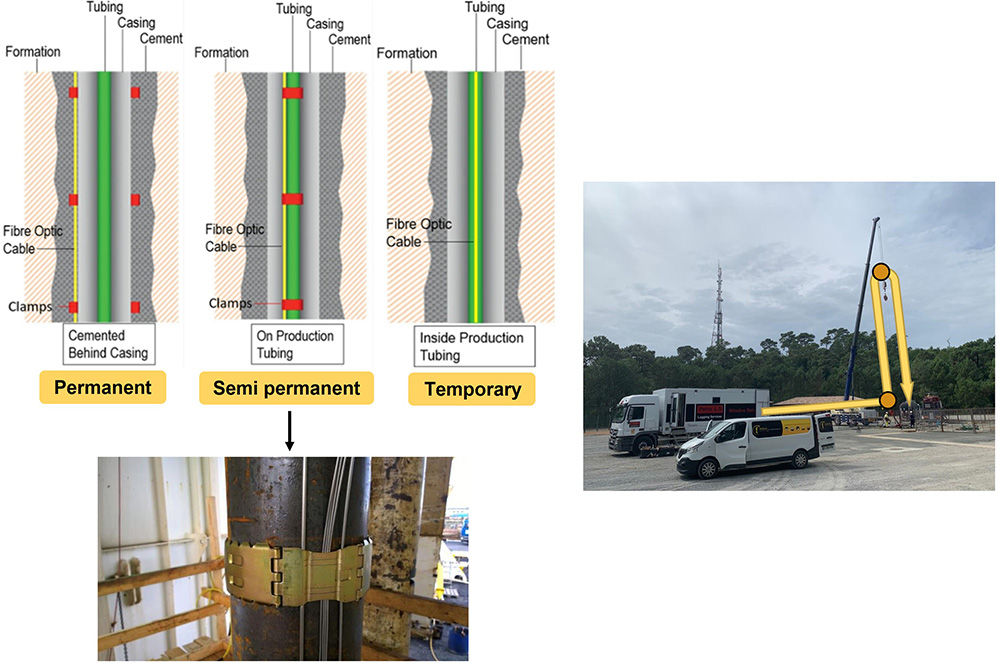

The monitoring of a well is needed to:

- look at the reservoirs dynamics and to optimize their production (flow profiling)

- provide a quick and efficient response to the failures observed on the completion parts, the tubings/casings and detect leaks

- monitor operations such as stimulation or hydraulic fracturation

- monitor the levels of the products stored in salt caverns or geological reservoirs.

Our patented technology of distributed fiber optic sensing offers major advantages over traditional methods.

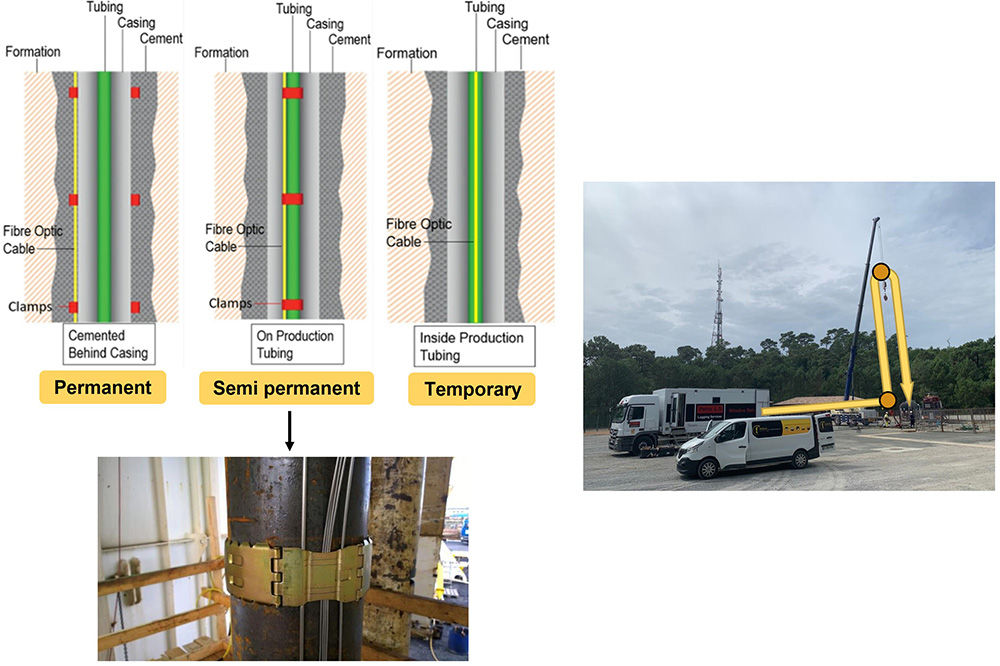

The FEBUS Optics interrogators have been developed and optimized to meet all the challenges of well monitoring and its many applications. Our embedded softwares (on our DAS, DTS, DSS) provide all the tools required to the data processing and are easily implemented in any third-party solutions (hardware or software implementation). The fiber optic cable can be permanently deployed during the well completion or temporarily via wireline or slickline.

The fiber optic sensing is a non-intrusive method that allows to optimize the monitoring and maintenance costs of the well. It also provides:

- acoustic information with the FEBUS A1 (DAS - Distributed Acoustic Sensing) like the "Noise Logging Tool"

- temperature data with the FEBUS T1-R (DTS - Distributed Temperature Sensing)

- strain information with the FEBUS G1-R (DSTS - Distributed Strain and Temperature Sensing)

Distributed, continuous and real-time data are obtained along the well.

The gauge length is also adaptable before and after the operation on the FEBUS A1 (DAS - Distributed Acoustic Sensing).

4). Seismic & Natural hazards

- Monitoring of natural hazards

- Underground imaging (Vertical Seismic Profiling, surface seismic)

- Optimization of the reservoir production (CO2, hydrocarbons...)

- Events detection and alerting in case of danger

Distributed fiber optic sensing presents significant advantages compared to traditional technologies. Indeed, the only prerequisite is having a fiber optic cable deployed, to launch a survey along the cable route. The cables can remain in place after the operation for use in the future (in the case of 4D seismic survey for example).

By giving access to one seismic receiver at each meter (down to 0.2m), distributed fiber optic sensing offers the best data density. By limiting the needs of equipments to make a survey, it also allows to reduce the costs.

FEBUS devices provide measurements of:

- vibrations with the FEBUS A1 (DAS - Distributed Acoustic Sensing)

- temperature with the FEBUS T1-R (DTS - Distributed Temperature Sensing)

- strain and temperature with the FEBUS G1-R (DSTS - Distributed Strain and Temperature Sensing)

Continously and real-time, distributed measurements generate reliable and precisely localized data.

FEBUS Optics solutions offer unique features:

- an adaptable gauge length during or after the acquisition (size of seismic receivers)

- access to raw data or real-time processed data thanks to provided embedded tools

- coverage of a very large frequency range (from 0 to 400)

5). Intrusion Detection

- Real-time alerting at all locations

- Prevention of malicious acts

- Complementarity with any surveillance systems (cameras, drones, etc...)

A factory, energy facility, underground gallery, border, military base or any other critical infrastructure can be exposed to intrusions risks, damages and thieves. They need reliable and continuous monitoring.

The FEBUS Optics Perimeter Intrusion Detection System (PIDS) is the best solution to:

- guarantee the security of a site

- facilitate a quick and adapted response

- save the acoustic print of the events.

Our distributed fiber optic sensing patented technologies and our integrated management software FOGuard Suite have state-of-the-art performances.

You benefit from the reliability and the availability of our perimeter protection solution.

Based on the FEBUS A1 technology, our intrusion monitoring system provides acoustic measurements, which are:

- distributed: measurements at all points along the installation, no dead zone

- continuous 24/7

- generated in real time (a reaction time of less than 2 seconds between event and alert)

- precisely localized (down to 1 meter).

6). Structural Health Monitoring

- Protection of the population and of the environment

- Costs optimization (investments and maintenance)

- OPEX and APEX pooling

As soon as the foundations are laid and all along the lifespan of an infrastructure, the FEBUS Optics solution in Structural Health Monitoring (SHM) allows to control the performances and the behavior of a structure. It ensures that no damage due to the environement and functional charges is produced, riding out any risk or danger for the infrastructure and the population.

Ensuring a continuous monitoring of a nuclear power plant, a water or tailing dam, a viaduct or a bridge, a tunnel, a building, a road or a railway is essential to:

- optimize the safety of the structure, the population and the environment

- ensure its functions, the regulatory compliance and increase its lifetime

- reduce the operation and maintenance costs.

The distributed fiber optic sensing offers important advantages:

- this technology is far more cost-effective than traditional methods, based on the installation of multiple sensors on the entire structure

- it is easy to implement since the deployment of a single sensor (the optical fiber) is enough

- the deployed cable does not need to be removed after the operation, which allows to ensure the monitoring along the lifespan of the asset, without replacement of the instrumentation

- a continuous monitoring is achieved

- the distributed measurements are spatially and temporally localized with a high precision.

The FEBUS interrogators provide measurements of:

- strain and temperature by means of the FEBUS G1-D (DSTS - Distributed Strain and Temperature Sensing) for dynamic measurements, of the FEBUS G1-C (portable version) for one-time investigations and of the FEBUS G1-R for maximal range acquisitions

- vibrations thanks to the FEBUS A1 (DAS - Distributed Acoustic Sensing); modal analysis, high frequency displacements...

- temperature using the FEBUS T1-R (DTS - Distributed Temperature Sensing).

Our devices are easy to be interfaced with any supervision system.

Placed in indoor or outdoor cabinets, they provide reliable and accurate data even in harsh environment:

- resistance to vibrating interferences (electric noise, rotating machinery, strong wind and swell for example) and to extreme temperatures

- dust and splashproof

- immunity to electromagnetic radiations (high-voltage grid, nuclear power plant...)

- stabillity of measurements in time.