FIBERBUILT PIPELINE

Calgary, Alberta, Canada

FIBERBUILT PIPELINE

!

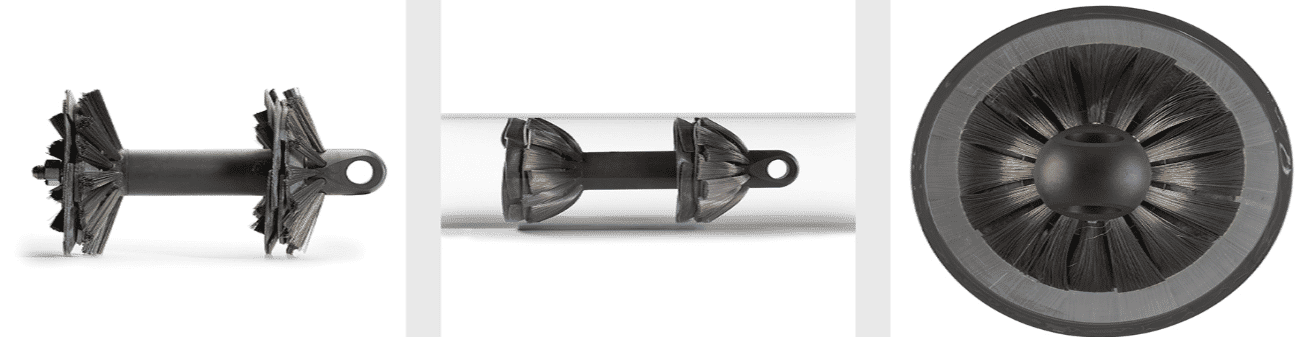

Unstoppable Pipeline Pigs for Pit Detection, Cleaning, and Prevention.

About FIBERBUILT PIPELINE

In 1959, Fiberbuilt began by crafting brooms and brushes by hand and we are now the only industrial brush manufacturer in western Canada with significant engineering expertise. This has allowed Fiberbuilt to become a leader in the development and application of unique brush technologies and technical developments across a variety of industries around the globe.

We specialize in the design and engineering of industry-specific solutions in the Energy, Forestry & Lumber and Golf industries. These industries depend on Fiberbuilt for quality products and practical solutions.

Fiberbuilt products are exported to over 40 countries worldwide from our modern 50,000 sq. ft. manufacturing facility in Calgary, Canada and our US warehouse in Pinehurst, North Carolina.