General Carbide

Greensburg, Pennsylvania, United States

General Carbide

!

Leaders in Tungsten Carbide Tooling Manufacturing for Industrial Wear & Metal Forming Applications.

About General Carbide

Our Story — From Powder to Polish

General Carbide is a vertically integrated manufacturer of finished tooling, wear parts and components for customers in more than two dozen market segments. The ISO 9001:2015-certified company employs more than 250 highly-skilled professionals in its production operations.

General Carbide has four facilities and sells its products throughout the United States, Canada, Mexico, Europe and Asia. The company was established in 1968 by Premo Pappafava (1926-2002) and is headquartered in Greensburg, PA, near Pittsburgh. Premo, a chemical engineer by training, started the company after working for several manufacturers in the Pittsburgh area following his graduation from Carnegie Tech.

Since 2002, Premo’s daughter, Mona Pappafava-Ray, has been at the helm of General Carbide. After joining the company in 1986, upon completion of her Industrial Management degree at Carnegie Mellon University, Mona held numerous staff and management positions before she was named General Carbide’s president in 1997.

As President and CEO, she has grown the company by transitioning from a manufacturer of semi-finished tooling to a leading producer of finished tooling. Mona has also led the company’s efforts to acquire several strategically significant businesses. Despite those changes, she has retained the family atmosphere that has been one of General Carbide’s distinguishing features from the beginning. Throughout her career, Mona has been the recipient of numerous awards for leadership and philanthropy.

As a woman-owned business, General Carbide has achieved certification from the Women’s Business Enterprise National Council (WBENC) and has received widespread recognition for business excellence.

Description of Services

The Versatility to Meet Your Specific Requirements

Whether you need finished tooling made of tungsten carbide or tool steels, we have the ability to meet the most exacting specifications by combining our expertise in manufacturing, applications engineering and metallurgy to help you achieve your objectives.

Our primary markets are:

- Automotive

- Can Tooling

- Fastener Tooling

- Oil & Gas

- P/M Compaction Tooling

- Stamping/Lamination Tooling

- Wire EDM Tooling

Other markets include:

- Aerospace

- Boring Bars

- Carbide Substrates

- Knives & Blades

- Rooftile Tooling

- Rotary Cutting Dies

- Specialty Tooling

- Wear Components

Life at General Carbide

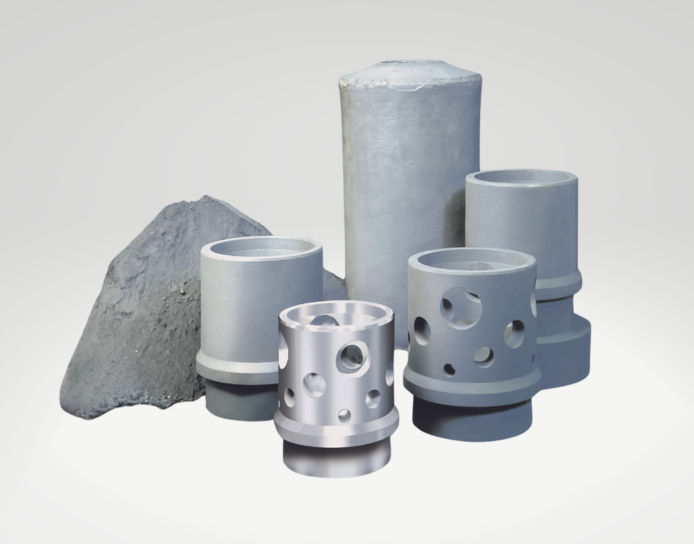

Tungsten carbide (WC), also referred to as cemented carbide, is a composite material manufactured by a process called powder metallurgy. Tungsten carbide powder, generally ranging in proportion between 70%-97% of the total weight, is mixed with a binder metal, usually cobalt or nickel, compacted in a die and then sintered in a furnace.

We recently opened a 50,000 square-foot production facility to house our finishing operations. To staff the facility, we created positions in management and production, including machinists, supervisors, managers, and custodians. The shop floor features an array of equipment, including grinders, lathes, EDM machines, and inspection systems, as well as a cleanroom and dust reduction system. This investment demonstrates our optimism at a time when many competitors have cut back.