Hipaq

Svenstrup J, Denmark

Hipaq

!

High pressure pumping systems. Air compressor systems.

About Hipaq

Custom engineered pressure systems.

More than 35 years of engineering

At HIPAQ we specialize in high-pressure engineering for Energy, Marine- and Industry applications. We are a highly specialized company with global ambitions in our field of expertise.

As a family-owned business with more than 35 years’ experience in pump- and air compressor technology, we know the challenges facing our customers every day, and do not compromise in any phase of the process.

Being an independent operator with no affiliations with any specific brands, we are free to source components from all of the leading manufacturers, focusing only on the best possible solution for the task at hand. We embrace new technologies and solutions to stay relevant in ever-changing markets.

Description of Services

Engineered to boost performance

At HIPAQ we design various pressurized systems for manufacturing companies and public institutions. The solutions are often made for concrete renovation, high pressure cleaning of heat exchangers, general maintenance, surface cleaning and removing rust and basecoats.

Combined heat and power plants use our high pressure solutions for major cleaning tasks and integrate the systems into the production plant. A large number of medium-sized and large companies specializing in cleaning choose solutions from HIPAQ.

These solutions are usually precisely adapted to customer-specific wishes and requirements. This also applies to servicing during the running-in period.

- Water blasting systems

- Cleaning systems

- Accessories for all pressure levels in stock

- Electrical, diesel driven, hydraulic driven systems

What we do

Engineered for absolute reliability

We take pride in being a preferred supplier to the energy sector, both on- and offshore, where the surrounding environment and working conditions are more extreme and challenging than anywhere else.

Coupled with the demand for smooth round-the-clock operations and no room for costly interruptions, our compressors and high-pressure pumping systems must offer total operational reliability and at the same time require a minimum of maintenance down-time.

HIPAQ supplies pressure systems for all of the typical energy applications, such as

Well testing • Well drilling • Mud transport • Pigging • Instrument air • Pipe and pipeline cleaning • Underwater cutting • Chemical injection and cleaning • Sand blasting • Water blasting • General cleaning

Wind farm cleaning and filtration tasks • Substation cleaning • Topside module cleaning

Offshore zone 2 compressor. Approved according to ATEX, DNV 2.7-1 and NORSOK Z-015. 3G Safe system means no exhaust flame traps. 21 m3 at 10 bar. Low noise emission, 83 dB(a) at 1m distance. Max weight 1000 kg/m2.

Rig safe air compressor. Twin 25 m3/min at 10 bar. DNV 2.7-1 approved container. 83 dB(A) at 1 m.

High pressure pump for chemical injection in zone 2 hazardous area. ATEX certified. Variable speed drive. AISI 316 stainless steel. 160 bar and 150 L/min.

Zone 2 air compressor. 1975 cfm at 150 psi. DNV 2.7-1 certified container and lifting slings. Diesel driven. ATEX directive. Sea water cooled. High ambient. Low noise level.

Zone 2 electric driven air compressor. 690V and 60 Hz. 42 m/min and 8 bar. NORSOK and ATEX approved. Air cooled.

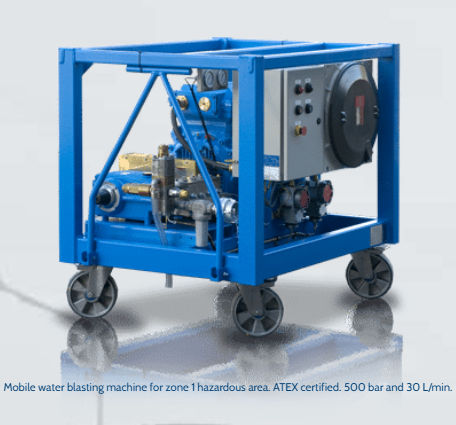

Mobile water blasting machine for zone 1 hazardous area. ATEX certified. 500 bar and 30 L/min.

Methanol injection skid. 300 bar and 500 L/min. Electric driven 6,6 kV 60 Hz. Noise canopy.

Offshore zone 2 compressor. Approved according to ATEX, DNV 2.7-1 and NORSOK Z-015. 3G Safe system means no exhaust flame traps. 21 m3 at 10 bar. Low noise emission, 83 dB(a) at 1m distance. Max weight 1000 kg/m2.

Rig safe air compressor. Twin 25 m3/min at 10 bar. DNV 2.7-1 approved container. 83 dB(A) at 1 m.

All HIPAQ products are customized for the task at hand, and for the physical space they will operate in. Typical ranges are air compressor systems up to 75 m3/min and 50 bar, and high-pressure systems up to 3000 bar.

HIPAQ delivers for all applications and all climates, whether arctic or tropical. Emphasis is put on compact design with small footprint, and low noise level, along with optimization of service procedures and intervals.

We have extensive knowledge in building for hazardous areas, according to IECEx/ATEX and the majority of machines can therefore be delivered for Zone 1 or Zone 2. HIPAQ has its own patented 3G Safe gas detection system.

Containers, skids and entire units can be delivered in accordance with DNV standards DNVGL-ST- E271, E272 and E273.

HIPAQ is experienced in building according to other standards as well, such as wind sector standards and NORSOK, which means our customers can trust us with even the most complex design, documentation and certification tasks.

We deliver full documentation packages to the highest standards, ensuring a problem-free approval and integration of any unit into its new location.