Interface FlUIDICS

Calgary, Alberta, Canada

Interface FlUIDICS

!

Precision Under Pressure. Microfluidics at Industrial Conditions.

About Interface FlUIDICS

At Interface Fluidics we provide critical fluid property data to energy companies globally to enable them to improve short-term financial performance, extract more value from their assets and make better decisions faster. We specialize in evaluating fluid performance under the toughest industrial conditions.

Since 2015 we’ve been leading the energy industry supported by our clients. Our pore-scale technologies and solutions give energy companies the critical insights they need into fluid behaviour. From subsurface plays to surface infrastructure, we can test changes in the system to protect assets, improve productivity, reduce cost, and save time. In the energy sector our services support:

- EOR Programs,

- Frac Fluid Optimization,

- MMP Testing,

- PVT and Fluid Phase Behaviour Tests,

- Flow Assurance and Formation Damage Projects,

- SAGD Operations, and more.

We’ve built our expertise and proven our SapphireLab platform working across major basins in North America, the Middle East, and Off-Shore.

Our versatile solutions, backed by deep experience, have proven successful across various industries. We’ve brought nano-technology from academic proof to practical tests delivering reliable insights.

We are a technology company providing energy industry clients insights into the interactions and properties of reservoir fluids to help them improve their financial performance, reduce their carbon footprint and ensure the responsible development of their oil and gas assets.

Description of Services

Services:

- Chemical EOR

Chemical Performance Evaluation

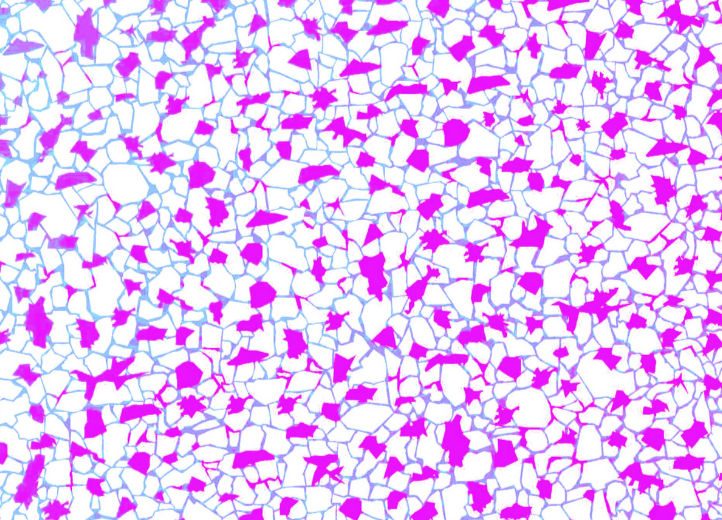

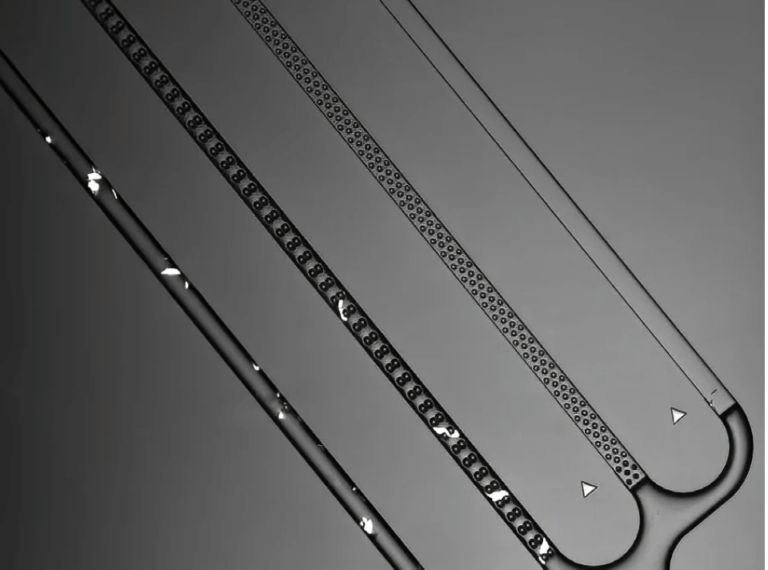

Optimize your chemical spend to extract maximum economic value from your polymer injection program. Interface delivers key insights on how different polymer blends behave in the reservoir. This helps you optimize your chemical spend to extract as much value from your assets as possible.

- Flowback

Fracturing Fluid Optimization

Make better cost-saving completions decisions that help increase hydrocarbon recovery and reduce fracturing fluid costs. Interface’s flowback fluids screening enables you to optimize your fracturing fluids spend and avoid fluid dosing and combinations that can damage your reservoir.

Interface Fluidics helps you evaluate a range of down-hole chemicals using your specific reservoir characteristics and fluids to identify top performing additives, allowing you to make faster, data-driven decisions.

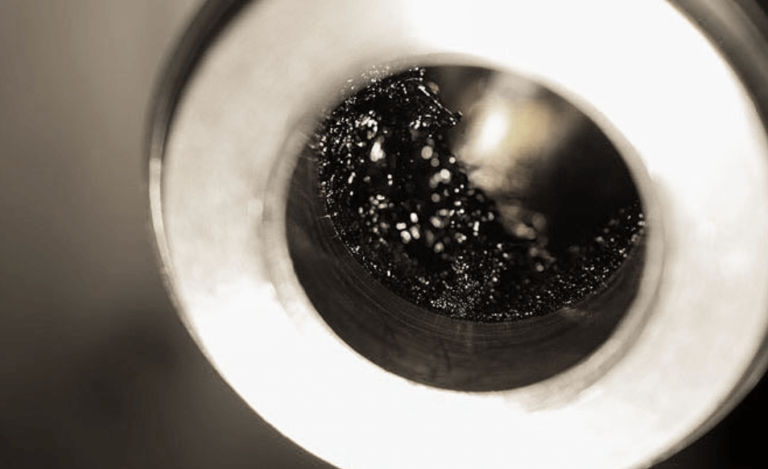

- Minimum Miscibility Pressure (MMP) and Composition

PVT & FLUID PHASE BEHAVIOUR

Rapid measurements for gas flooding

Quickly determine miscibility conditions for your gas flooding operation with a variety of gas compositions. MMP measurements provide you the minimum pressure required for miscible oil displacement in your reservoir. This critical measurement helps you avoid unwanted early gas breakthrough, which reduces oil recovery.

Developed in partnership with Equinor, this test is proven to deliver accurate results in as little as 30 minutes with as little as 0.1ml of oil sample per data point.

- PVT and Fluid Phase Behaviour

Faster and more cost effective high-pressure, high-temperature analysis of oil and gas samples.

Interface’s suite of standard and advanced PVT analysis solutions require less than 1ml of fluid per evaluation and gets you results much faster than conventional PVT methods.

- Regain Conductivity

A Rapid Regain Alternative

Reducing cost and time while increasing run-to-run repeatability would be a step change in how friction reducers are evaluated and potentially revolutionize the formation damage measurement industry.

- Thermal Solvent SAGD

SAGD Fluid Performance Screening

Properly assess how steam additives influence your reservoir. Interface helps you select a solvent, alkaline additive, or non-condensable gas to supplement your steam in the field.

After almost a decade of extensive research, Interface’s SAGD performance evaluation testing is proven to provide pore-scale level data that shows the mechanisms behind how steam additives work.

- Wax Control

Wax coverage and conditions for management

Highly accurate measurements for managing wax

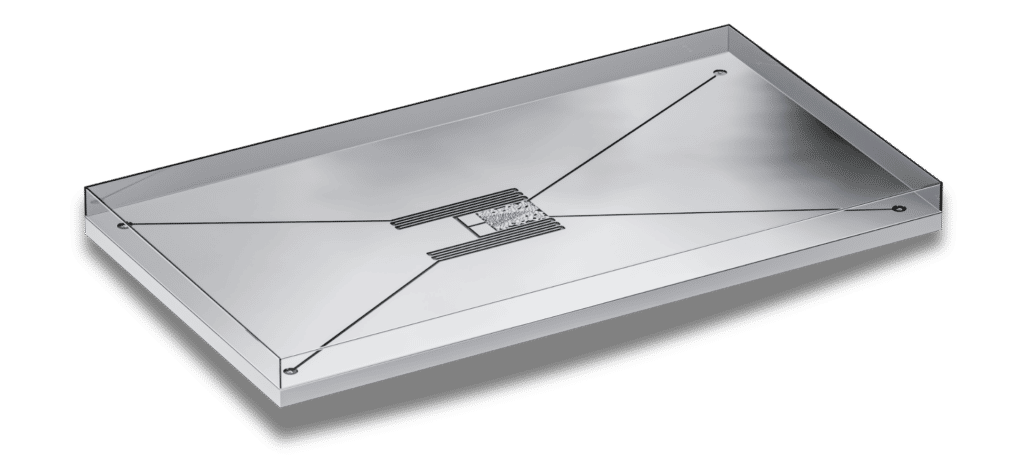

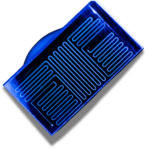

The SaphireLab Platform uses Microfluidic chips that are used to visualize and quantify wax appearance, disappearance and coverage.

Samples are run through a variety of tests to determine an accurate Wax Appearance and Disappearance Temperature. Other tests can be conducted to understand the efficacy of different wax mitigation strategies. SapphireLab can help you hone your understanding of the correct chemistry and concentrations to best execute a well defined wax management program.

SapphireLab can accommodate extreme conditions as the platform can operate up to 1000bar/15000psi and 200C°/400F°.

What we do

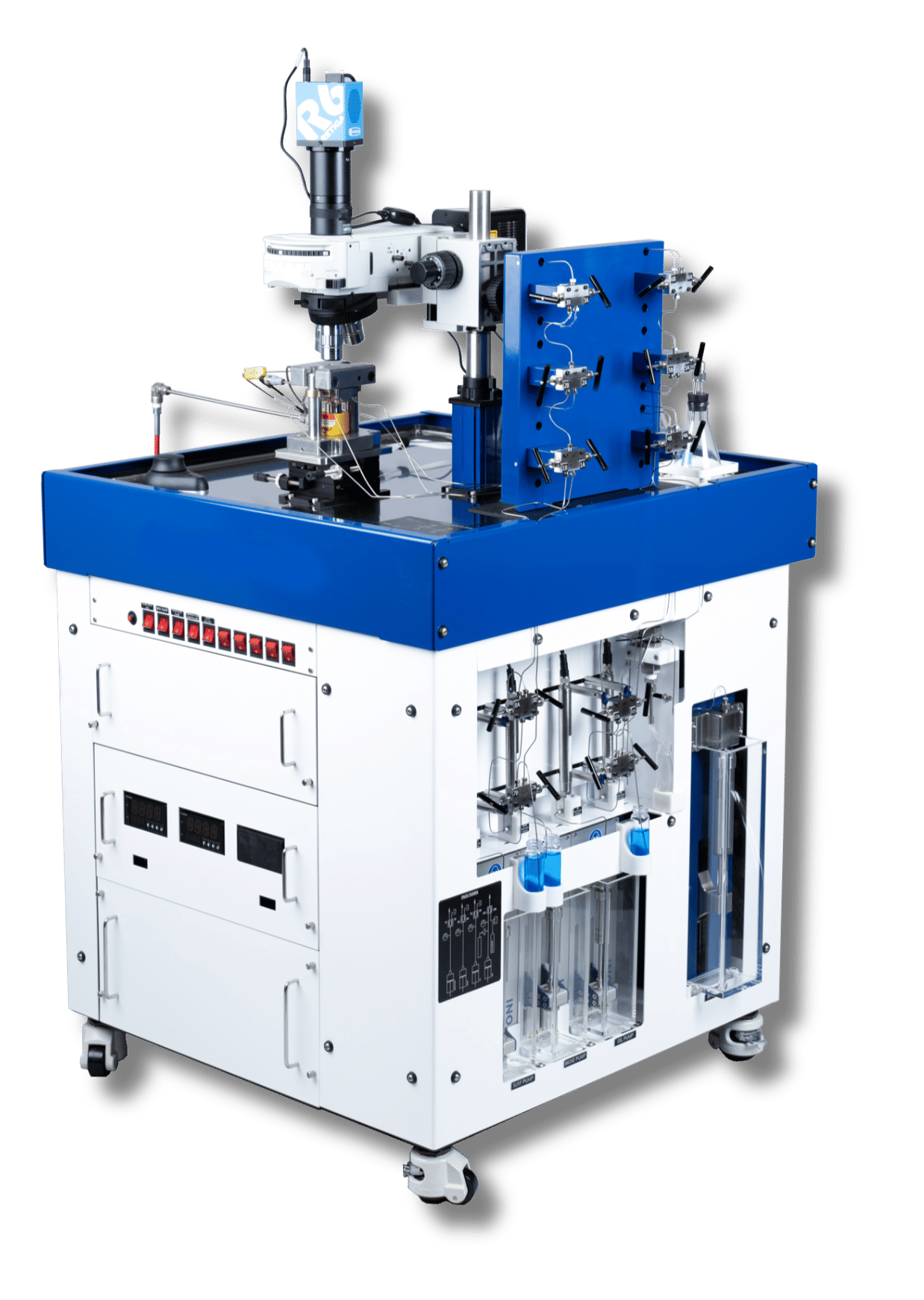

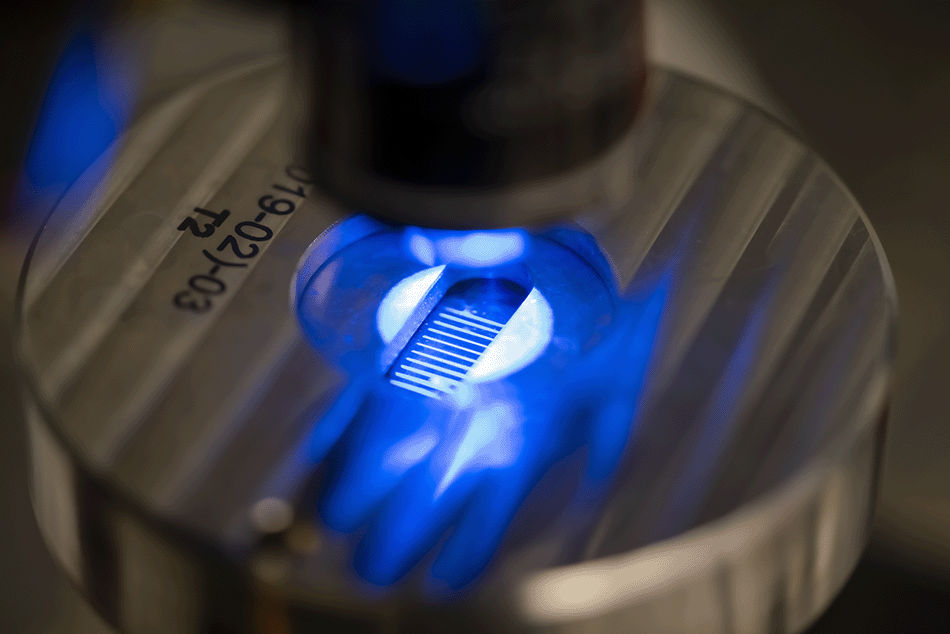

SapphireLab:

A Turnkey Microfluidic System

Unlock New Insights in Industrial Fluid Analysis

Introducing ground-breaking capabilities for microfluidic testing at unprecedented pressures, temperatures and automation.

Who Uses SapphireLab:

- Researchers

- Chemistry Providers

- Completions Engineers

- Production Engineers

- Reservoir Engineers

- Service Laboratories

A Multi-Purpose Tool for Fluid Analysis

SapphireLab is a ready-to-use solution that can handle most of the work done today by a PVT Cell, Core Flood, Slim Tube, Proppant Pack and other specialty tools.

Deeper insights into fluid behaviour with a single system:

- Carbon storage

- Flow assurance

- Formation damage

- Enhanced oil recovery

- Completion fluid evaluation

- Phase Behaviour

- And more

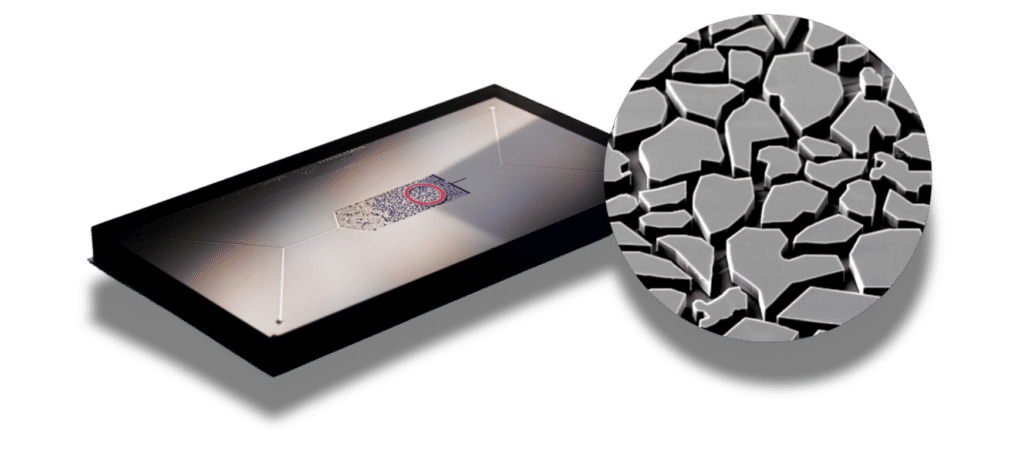

Microfluidic chip includes silicon base layer with etched channels and porous structure, and a bonded glass layer.

Next Generation Fluid Analysis For Your Laboratory

SapphireLab leverages microfluidic technology to deliver critical data about how fluids behave underground. Our customers can increase production and reduce expenses by:

- Visual access

- Reduced sample requirements

- Highly controlled and customizable porous media