Maxon

Taunton, Massachusetts, United States

Maxon

!

We love electric drives.

About Maxon

maxon company history.

Our roots are in Switzerland, but our drives set things in motion worldwide. The history of maxon is marked by curiosity, innovation, and the courage to constantly embrace change.

1961 – The start of it all

On December 5, 1961, Interelectric AG is founded as a production site for BRAUN, the electrical engineering company based in Frankfurt. Where? In picturesque Sachseln, in the canton of Obwalden, Switzerland, of all places.

1963 – Shearing foils for BRAUN shavers

The company begins producing galvanoplastic – metal-coated – items. The most important of these are the shearing foils for the popular BRAUN shavers. A development department for electromechanical devices is also established.

1968/1969 – Development of the maxon DC motor

The cornerstone for all subsequent innovations is laid: with the development of DC motors with an ironless rotor. The benefit: The absence of iron in the rotor almost doubles the efficiency in comparison with traditional motors. The diamond-shaped winding and the manufacturing process are patented. maxon is registered as a trademark.

1979 – Founding of maxon motor GmbH

maxon motors are used in everyday devices such as pocket calculators, tape recorders, and video equipment. Interelectric AG Munich founds its first subsidiary under the name maxon motor GmbH.

1981 – US expansion

The North American market is becoming increasingly important for the Obwalden-based company. The result: Interelectric AG takes over its US sales partner in San Francisco, and renames it maxon precision motors, inc.

1989 – Production in Germany

Interelectric opens a production plant in Sexau (Germany) for the manufacture of planetary and spur gearheads.

1997 – First rover on Mars

The first rover to ever land on the Red Planet, NASA’s Sojourner, has eleven maxon DC motors on board.

1999 – We become maxon motor

Before the start of the new millennium, the company restructures itself. “Interelectric” becomes “maxon motor ag.”

2004 – Next Mars landing

The NASA rovers Spirit and Opportunity land on Mars. They are each powered by 35 maxon motors, which drive the robot arms, the rock abrasion tool, the control mechanism, the camera controls, and the six high-tech wheels.

2004 – New production site in Hungary

maxon motor ag opens a new production building in Veszprém (Hungary), where components for the drive system are manufactured.

2007 – Founding of Medical unit

The Medical unit is established to develop high-precision drives for applications such as insulin pumps, prosthetics, and surgical robots.

2010 - Innovation award for motor for extreme conditions

The 2010 innovation award of the HKZ (Chamber of Commerce of Central Switzerland) went to maxon motor. The company swayed the jury with the new precision motor for extreme conditions, the maxon EC 22 HD. It can withstand temperatures of more than 200°C.

2012 – A world first: the online configurator

maxon presents a world premiere with the online-configurable maxon X drives. Motors, gearheads, sensors, and controllers can be personalized and ordered with just a few clicks.

2013 – Production start in South Korea

To strengthen its East Asia business, maxon motor manufacturing Co., Ltd. begins production of the first brushless DC motors in Sejong (South Korea).

2014 – maxon chases down a comet

For the first time in history, maxon drives land on a comet: For 10 years, the European space probe Rosetta traveled through space to reach the comet 67P/Churyumov-Gerasimenko. Two maxon DC motors withstood 10 whole years in vacuum.

2015 – Launching the e-bike business

maxon motor enters the e-bike business with a highly powerful yet compact rear-wheel drive. Designed and made in Switzerland, this drive accelerates a bicycle from 0 to 30 km/h in only 3 seconds.

2016 – First Cybathlon

The ETH Zurich organizes the first Cybathlon, an event in which more than 80 teams from across the world take part, with machine-assisted pilots competing against each other in six disciplines. Right from the start, maxon has been supporting this huge event as a sponsor and partner.

2017 – Acquisition of zub machine

maxon motor acquires the Swiss company zub machine control AG, expanding its product portfolio with intelligent master controllers.

2018 – Acquisition of Parvalux UK

The maxon motor Group acquires British geared motor manufacturer Parvalux Electric Motors Ltd., thus expanding its portfolio to include powerful AC and DC drives.

2018 – Inauguration of the Innovation Center

The maxon Innovation Center at the headquarters in Switzerland opens its doors for the first time. Here, micro drives for use in medical technology are produced in cutting-edge clean rooms.

2019 – Production in the USA

The first production site in the USA opens in March 2019. The facility in Taunton, Massachusetts, offers space for design engineering, production, and sales.

2019 – System solutions gain importance

maxon transforms from a supplier of components to a systems provider. Together with customers, the company increasingly develops complete mechatronic solutions, consisting of a motor, gearhead, sensors, controller, batteries, and software.

2019 – Rebranding as maxon

maxon motor becomes maxon. The company adopts a new global structure to position itself in the system market and enable future growth. The new brand identity epitomizes this strategy.

2020 – New motors for the UAV and robotics market

maxon partners with drone start-up Flybotix to develop performance-optimized BLDC motors for an innovative inspection drone. Together with robotics start-up ANYbotics, maxon develops drive systems for autonomous inspection robots.

2021 – On Mars for the third time

The Perseverance rover lands on Mars. Several maxon electric drives are used for this ambitious mission – for example, for the first flight of the mission’s helicopter or for moving the robotic arm that navigates the rock samples.

2022 – More than 60 years of maxon

maxon celebrates its anniversary with more than 3,000 employees worldwide, 9 production sites and a sales network in 40 countries.

Description of Services

Our business units.

Our drives are used wherever there can be no compromises regarding precision, performance, reliability, and quality. Experts from our business units work on this every day.

Medical technology

Nowhere are the requirements for technical components as high as in medical applications: Absolute precision, sterilizability, minimal vibration, power density in a compact size, and low heat build-up in the drive are essential.

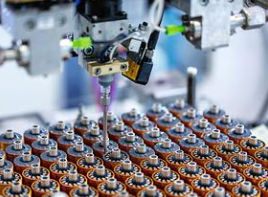

Industrial automation

Industry 4.0, IoT, and AI require complex mechatronic drive systems, whose components are perfectly synchronized. We constantly raise the bar for precision, sustainability, and reliability while keeping costs in mind.

Aerospace

Whether it is long-haul aircraft, UAVs, or Mars rovers, hundreds of powerful drive systems are required for liftoff. Our components remain highly precise even in extreme environments, propelling space missions forward and improving the passenger experience.

Mobility solutions

The future of mobility is electric. Our system solutions tailored to the market serve as the foundation for implementing complex applications, such as modular wheel drives, adaptive chassis systems, electric brakes, lightweight e-bike drives, battery management systems or autonomous logistics robots.

What we do

We drive the world.

We develop drives that are among the best in the world. We advance technologies that save human lives on Earth, increase safety in driving and flying, and enable robotic arms to operate in space. In pursuit of these goals, we continuously work towards improving and evolving our drive systems.

Finding the perfect solution.

By combining brushed and brushless DC motors, gearheads, sensors, and controllers, we create highly precise mechatronic drive systems. As a high-tech company, we are active worldwide in the fields of medical technology, aerospace, robotics, mobility solutions, and automated industrial applications.

Life at Maxon

What sets us apart.

-

Mission

Our goal is to continuously develop better drive systems and become the digital market leader for customized drive technologies and services. Our focus is on tailoring our products, systems, and services to meet the needs of both today's and tomorrow's industry.

-

Taking action

We take unconventional paths and foster new ideas. At the same time, we are mindful of our responsibility: We minimize our impact on the environment and resources, recycle valuable raw materials, and develop solutions that bring sustainable progress for all.

-

Promise to our customers

Uncompromising quality, pioneering innovation, and cost-effectiveness. In close collaboration with our customers, we develop high-precision drive systems at competitive prices. We will not be satisfied until we have found the perfect drive solution for any application.