MMT

Natick, Massachusetts, United States

MMT

!

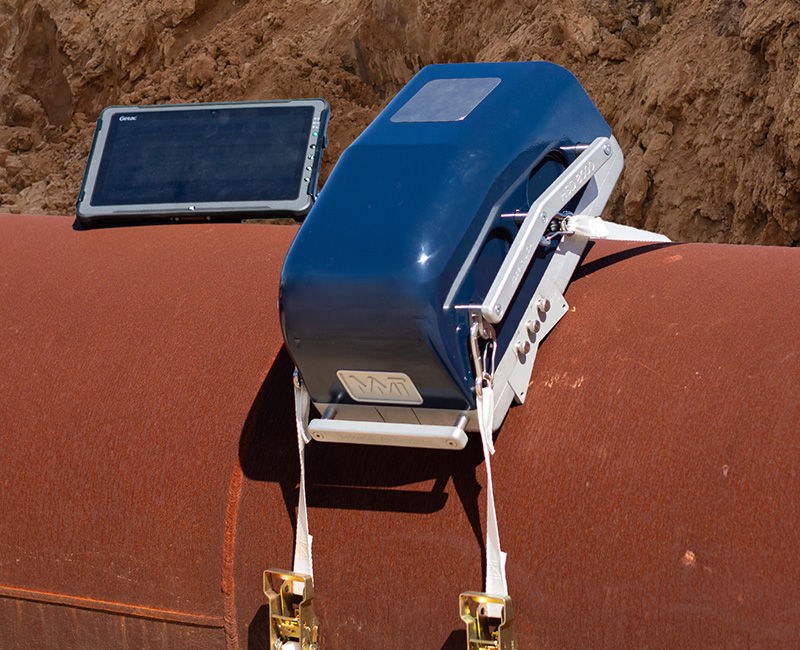

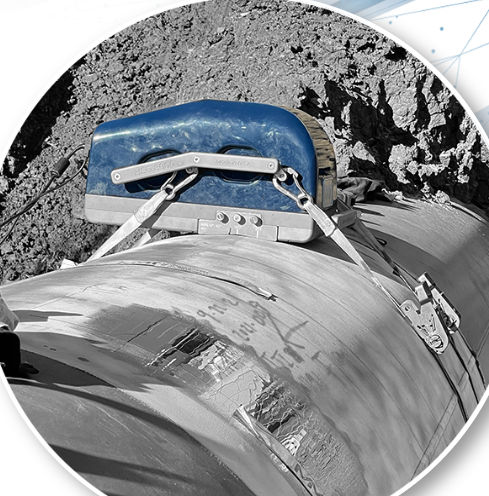

Nondestructive Verification and Toughness Technology.

About MMT

Quantify the durability of pipelines and other infrastructures through nondestructive and toughness testing, enabling data-driven decisions without service interruption.

The Standard for Material Verification

From invention to commercial product solutions, MMT was founded in 2014 to develop and commercialize new instrumentation to accurately measure the mechanical properties of oil and gas pipelines without interrupting service and extracting pipe cutouts for laboratory testing. Today, the MMT team brings a broad range of experience to deliver products, training and technical support, providing the highest accuracy standard in the market, driving the lowest total cost of testing for continuous and safe pipeline operation.

Description of Services

- Critical Pipeline Integrity Health and Performance Data

MMT is the global leader in nondestructive material testing and toughness verification technologies. Our HSD (hardness, strength and ductility) and BTM (blade toughness meter) testers provide cutting-edge solutions by working together to deliver complete records at industry-leading accuracy.

- Fast and Accurate Reporting to Meet TVC Requirements

Get instant data reporting coupled with MMT advanced data analysis and fit-for-purpose reports.

- Extensive Material Data Verification

MMT processes and analyzes all data for every test completed every time. Get consistent, laboratory-quality data verification with advanced FEA (finite element analysis) in an NDE environment for the strength and toughness of pipeline materials, including seams, pipe body and more.

- Zero Test Failure

Frictional sliding technology samples a greater volume of material to provide the most reliable averages every time.

- Going Beyond PHMSA’s Mega Rule (RIN 2)

MMT partners with pipeline operators and NDE service partners to define the new norm for material verification.

- The Most Robust Training Program in the Industry

MMT ensures the quality and consistency of testing procedures for accurate results and safe operations.

What we do

Lowest Total Cost of Testing

More data points deliver superior strength and toughness analysis.

MMT is becoming the standard for extending the life of metal infrastructure worldwide and with the lowest total cost of testing.

With Zero Test Failure, fewer tests are required and less frequent, making it a cost-effective solution. MMT provides more data points, allowing for strength and toughness analysis that surpasses the standard TVC requirements with a single test.

The increased accuracy of MMT drives better decision-making, promotes safety and lowers risks for metal infrastructure.

Life at MMT

Our Mission

Empowering data-driven decisions for the safe and environmentally sustainable operation of the world’s pipeline, nuclear, industrial and defense infrastructures through technologies providing laboratory-quality metal strength and toughness properties without service interruption.

Our Vision

Quantifying The Durability Of Our World’s Energy Infrastructure.