Novitech

Vaughan, Ontario, Canada

Novitech

!

Novitech is an industry leading in-line inspection service and technology development company.

About Novitech

Novitech provides in-line pipeline inspection and mapping services that meet or exceed the expectations of our clients and deliver upon our Pledge for Excellence.

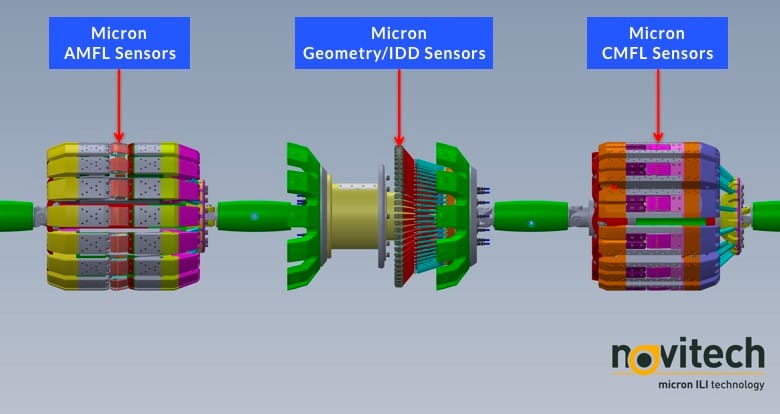

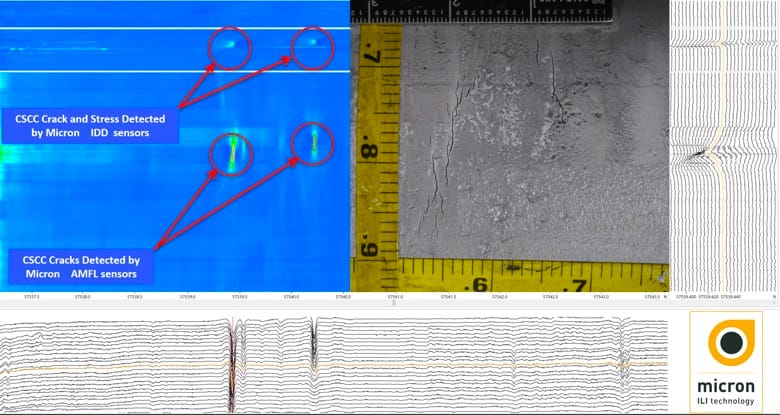

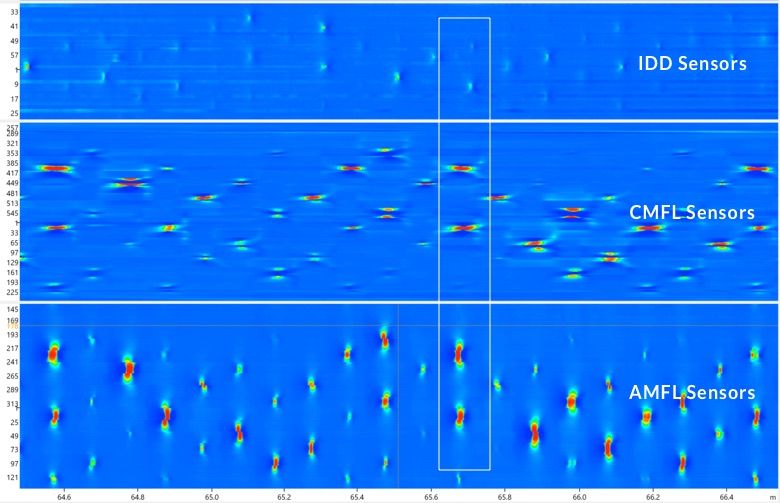

Novitech’s innovation driven culture is supported by individuals with decades of experience, as well as strong customer partnerships. This has been and will remain the key to maintaining our leadership position with technology innovations in the pipeline industry’s MFL Crack and Flaw detection.

We pledge to operate with the highest standards of ethics, performance, and compliance through the entire project cycle. Projects will be executed with project management best practices, integrity, individual responsibility, and accountability to ensure the success of every pipeline inspection.

What we do