Nuwave Laser

Converse, Texas, United States

Nuwave Laser

!

Your Partner in Precision Surface Cleaning.

About Nuwave Laser

Nuwave Laser is a family-owned business specializing in advanced laser cleaning solutions for industrial applications. We understand the complexities of industrial maintenance and the importance of efficient, precise cleaning processes.

The Right Expertise

We offer a range of laser cleaning machines designed to address various industrial cleaning needs. Our team of experts stays at the forefront of laser cleaning technology, continuously refining our solutions to meet evolving industry demands.

Our Approach

At Nuwave Laser, we recognize that each industrial cleaning challenge is unique. Our approach involves:

- Understanding your specific requirements

- Assessing the most suitable laser cleaning solution for your application

- Providing expert guidance on implementation and best practices

We believe in tailoring our services to match the distinct needs of each client, ensuring optimal results for your particular industrial environment.

Our Commitment

As a family-owned business, we’re committed to:

- Delivering high-quality, reliable laser cleaning machines

- Providing exceptional, personalized customer service

- Promoting sustainable cleaning practices in industrial maintenance

- Continual innovation in laser cleaning technology

Description of Services

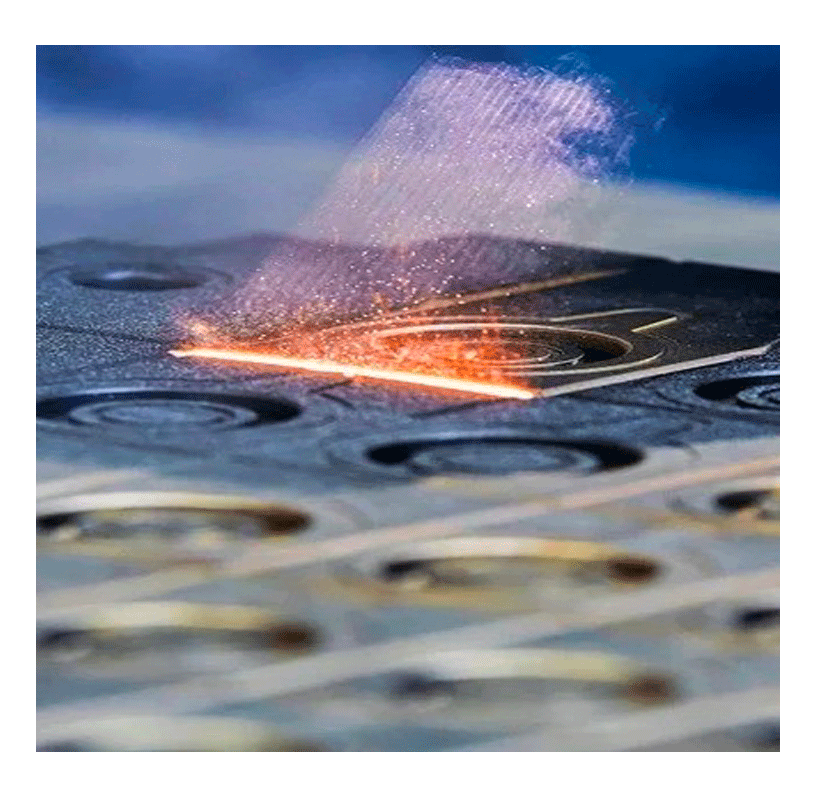

What Is Laser Cleaning?

Laser cleaning is a non-contact method of removing surface contaminants, such as rust, dirt, dust, and oxidation, from a variety of materials. It uses a focused beam of light energy to break up and remove the contaminants without causing damage to the underlying substrate. Cleaning with lasers does not produce any chemical waste, making it an environmentally friendly option. It is also highly precise and can target specific areas, even complex shapes, without affecting surrounding areas.

Put The Power of Light into Your Hands

Nuwave offers top-of-the-line laser machines that put the power in your hands, enabling you to gain the flexibility to clean on your schedule.

Pulse Laser Cleaning Machines

- Scan width up to 6"

- Precision cleaning

- Can be used on most surfaces

Continuous Wave Laser Cleaning Machines

- Scan width up to 23"

- High Energy/Deep Penetration

- Heavy Corrosion Cleaning

Whether you’re in manufacturing, automotive, or any industry requiring meticulous surface preparation, our user-friendly machines deliver professional-grade results. Don’t just clean – revolutionize your surface prep and maintenance routine with a Nuwave machine. Take the first step towards efficiency and excellence today.

What we do

Applications

- Rust Removal

- Grease Removal

- Paint Removal

- Surface Preparation

- Surface Decontamination

- Oxide Removal

- Coating Removal

- Metal Cleaner

- Welding Prep

- NDI/NDT

Laser technology offers versatile solutions for surface preparation and maintenance, all while providing a non-abrasive and environmentally friendly alternative to traditional cleaning methods.

Powerful Laser Cleaning Applications:

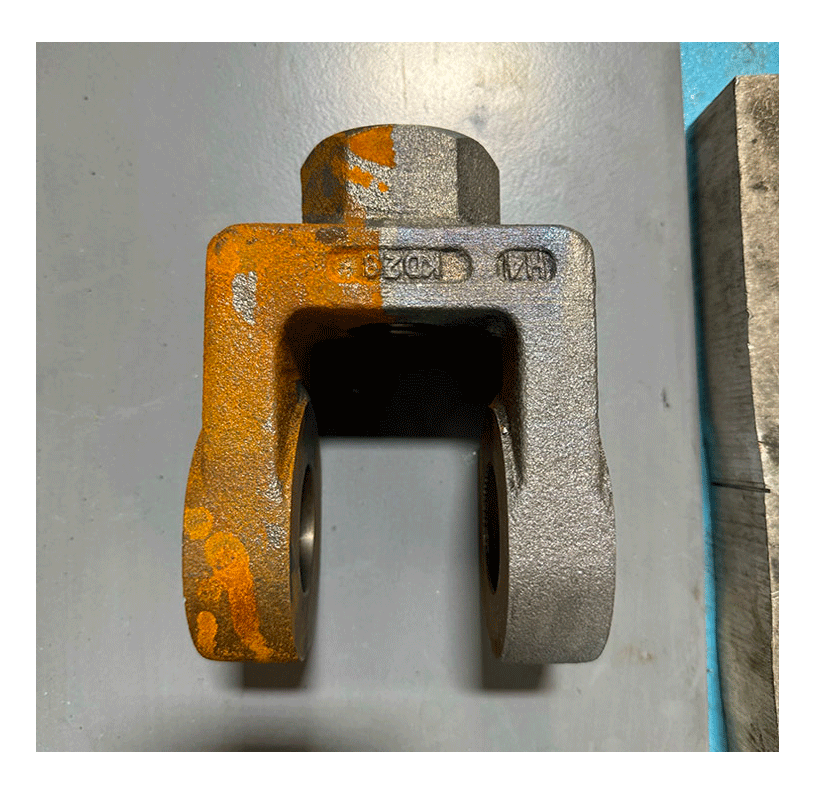

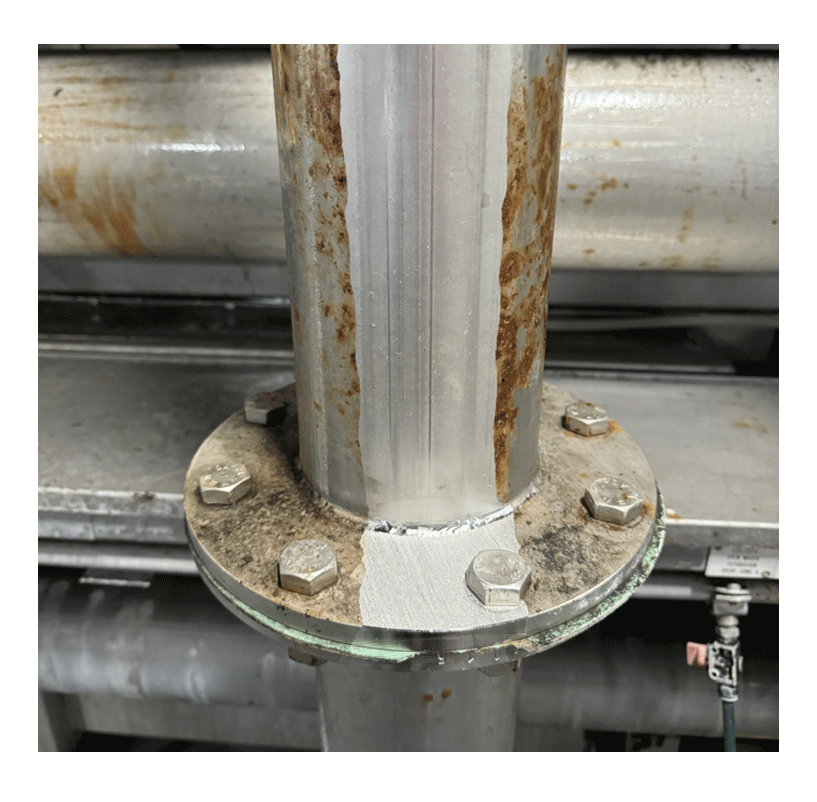

Rust Removal

- Efficiently eliminates rust without damaging the underlying material

- Ideal for metal surfaces in various industries

- Extends the life of your equipment and structures

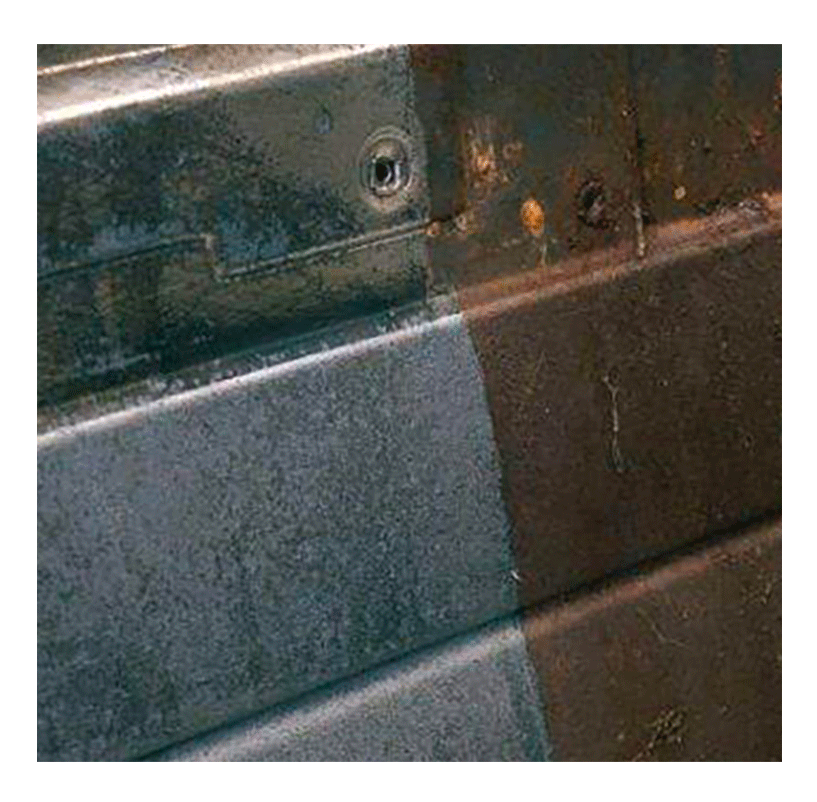

Paint Removal

- Precisely strips away old paint layers

- Perfect for restoration projects and surface preparation

- Environmentally friendly alternative to chemical stripping

Surface Preparation

- Removes rust and coatings with precision

- Prolongs equipment and structural longevity

- Delivers reliable results across industries

Coating Removal

- Targets specific layers without damaging the substrate

- Effective on various coatings and surfaces

- Creates ideal surface for new coating adhesion

Grease Removal

- Vaporizes grease and oil residues

- Leaves surfaces clean and ready for use

- Ideal for industrial machinery and equipment

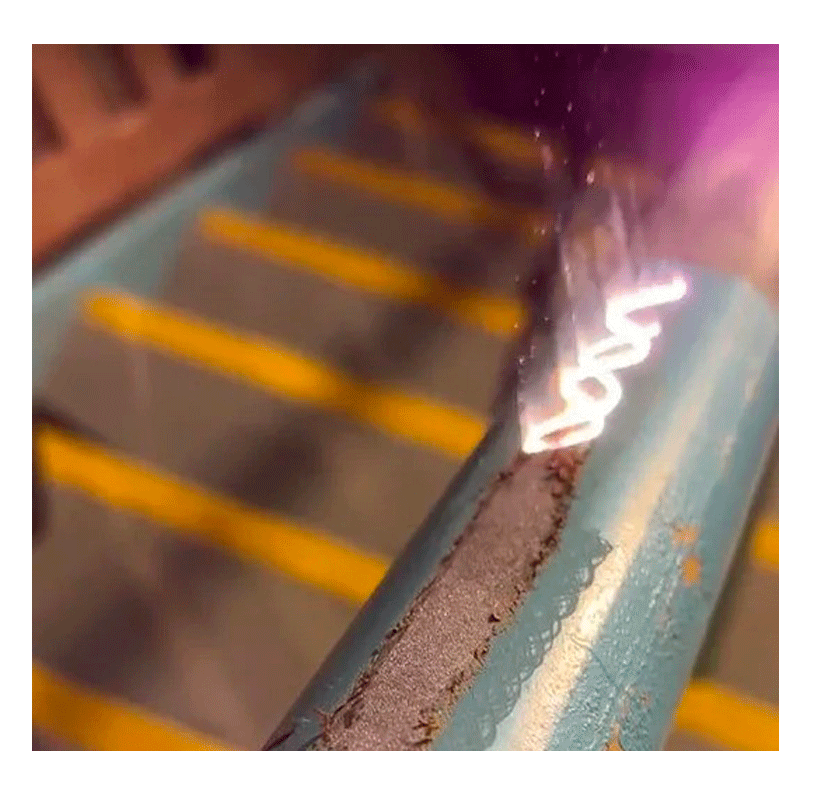

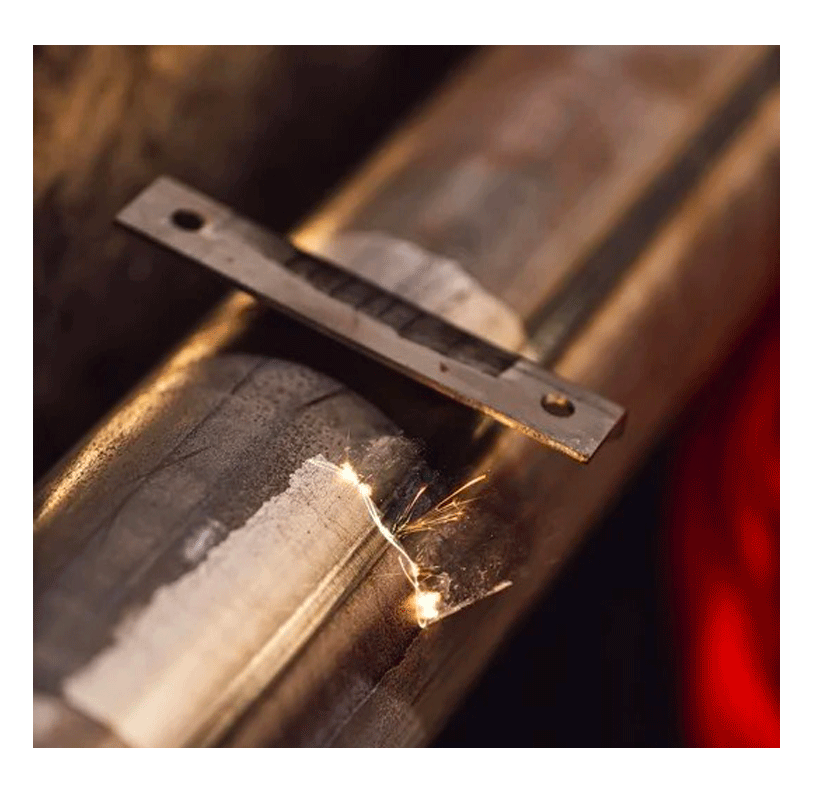

Welding Prep

- Cleans surfaces for optimal weld quality

- Improves weld strength and appearance

- Increases efficiency in manufacturing processes

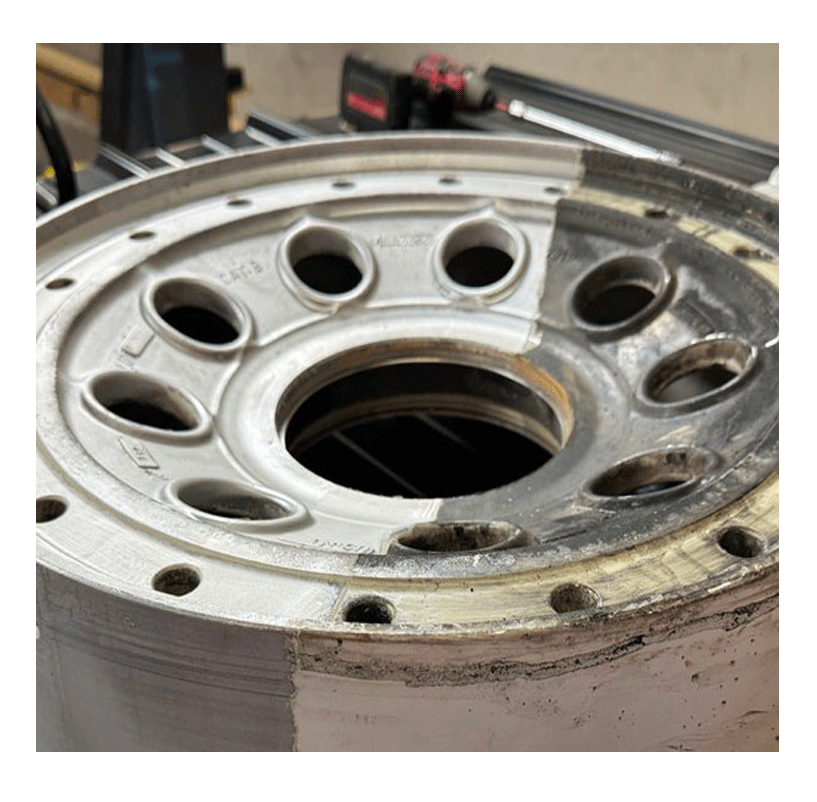

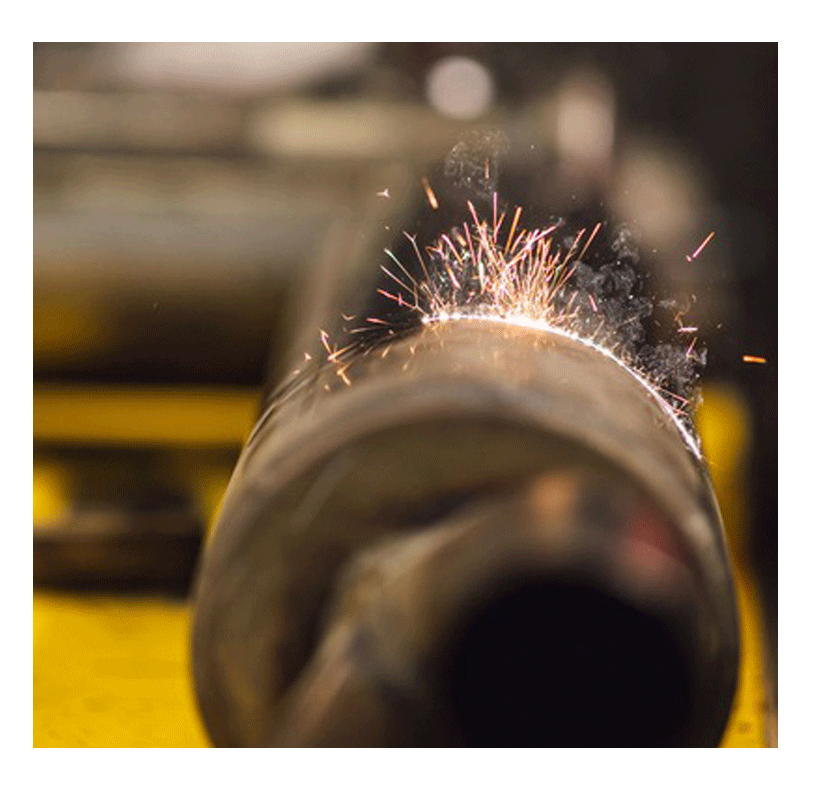

Oxide Removal

- Cleans oxidized metal surfaces quickly

- Improves surface quality for further processing

- Essential for electronics and semiconductor manufacturing

Metal Cleaner

- Removes rust, oxide, paint, coatings

- Maintains structural integrity and longevity

- Effective in aerospace, automotive, manufacturing, and marine industries

Surface Decontamination

- Removes hazardous materials safely

- Effective for nuclear and chemical industries

- Reduces health risks associated with contamination

NDI/NDT (Non-Destructive Inspection/ Testing)

- Prepares surfaces for accurate inspections

- Enhances the reliability of test results

- Crucial for aerospace and automotive industries

Life at Nuwave Laser

Benefits of Laser Cleaning

Eco Friendly

Laser cleaning avoids chemicals and solvents

Cost Effective

Long-term cost savings through reduced consumables

Precision Cleaning

Precisely target surfaces, minimizing damage to delicate parts

Reduced Downtime

Boosts operational efficiency and productivity

Consistency

Ensures the consistent quality required for some industries

Versatility

Removes rust and other contaminants from multiple types of substrates.

Non Contact

Cleans without touching the surface, preventing wear or damage.

Safety

With training, can be safer for operators than traditional chemical-based cleaning methods.