Ofar

Visano, Lombardia, Italy

Ofar

!

A leading supplier of forged components for a wide range of markets and industrial applications such as Oil&Gas, Mechanics, Steel, Shipbuilding, Petrochemical and Power Generation.

About Ofar

Ofar was established in 1961 and it is a leading supplier of forged components for a wide range of markets and industrial applications such as Oil&Gas, Mechanics, Steel, Shipbuilding, Petrochemical and Power Generation.

The company joined GIVA Group in 1985 and its remarkable growth led to the opening of an additional plant in 2011 dedicated mainly to the power generation market.

In 2019, OFAR broadened its capabilities thanks to the merger with Forges. This partnership gave birth to a worldwide leader in the open die forging industry that today boasts three cutting-edge production plants. Based in the North of Italy with 200.000 sq mt, it has an annual production capability of more than 100.000 tons.

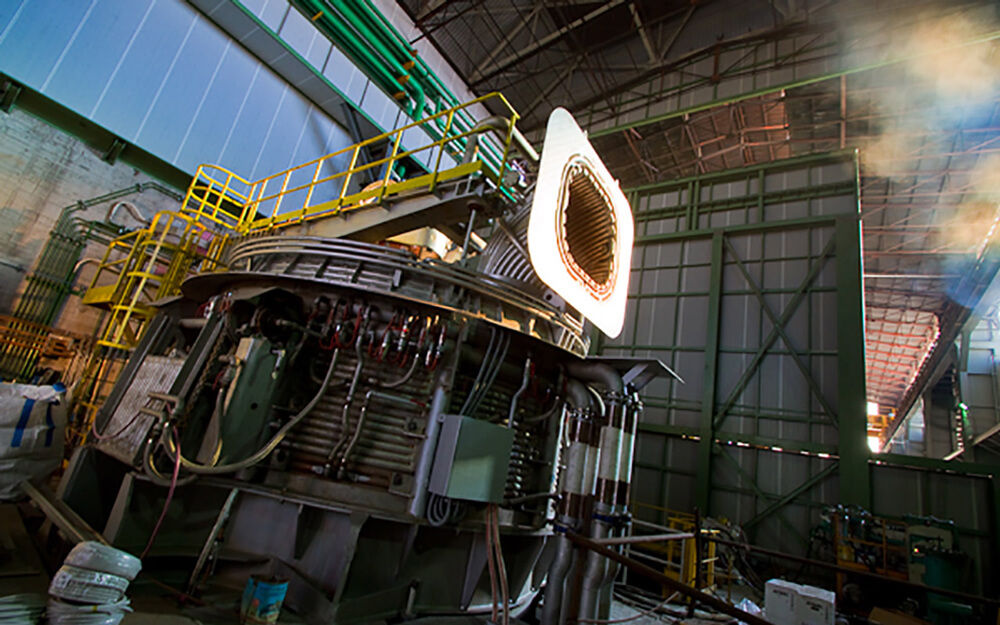

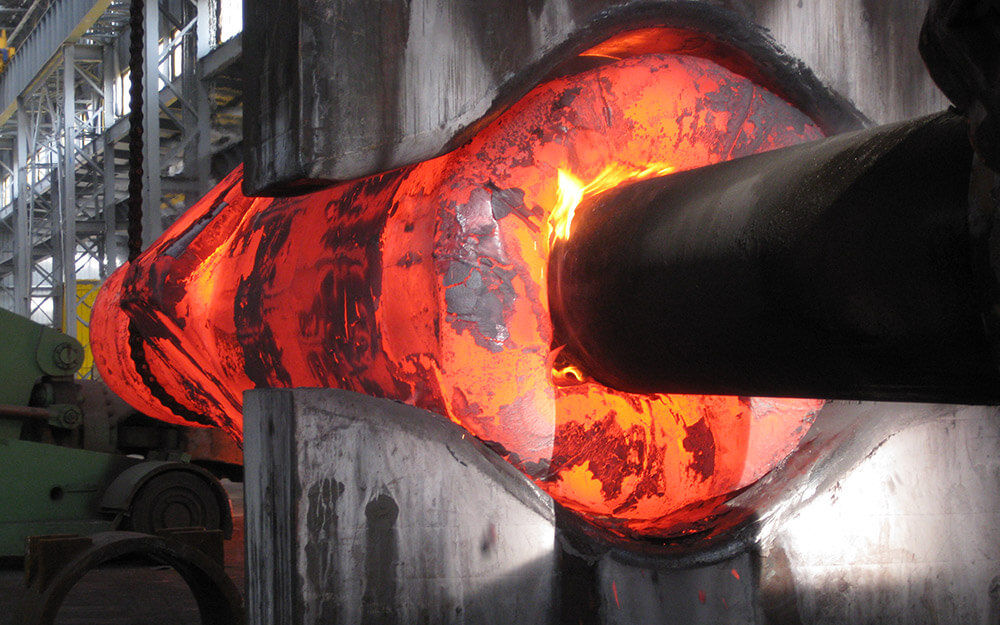

OFAR produces forgings from 500 Kg to 150 tons. This exceptional wide range is made possible by 5 production lines and 5 presses of respectively 13.000, 6.000, 5.000, 3.000 and 2.500 tons. We built our success and worldwide customer’s trust on our strength and innovation that are characterized by traditional and drop-bottom furnaces, horizontal tanks up to 20 m, vertical furnaces up to 16 m and an innovative system of spray quenching. Ofar also holds two metal testing laboratories and it performs rough and finish machining up to 28 m.

Description of Services

Delivering value to worldwide infrastructures

- Oil & Gas

- Petrochemical

- Power Generation

- Mechanical Engineering

- Shipbuilding

What we do

Technology driven processes

PEG

Frozen process

Process control

Quality

OFAR R&D is fulfilled within the Giva Group dimension thanks to a dedicated Process Engineering Group (PEG) aimed to support the development of industrial processes by means of shared technological tools, database and know-how.

Sophisticated digital simulation tools drive the use of internal technological capability. This enhances the forecast capacities and decreases the discard rate and related cost.

The final master frame developed by our process engineers, associated to each and every product, is a frozen process. Such a concept allows repeatedly achievement of the requested and proven quality of the product. Our process engineers are 24hrs reliable for so designed master process. Continuous surveillance control and feedback make part of that responsibility. As a result, the final quality of the product is not negotiable.

Life at Ofar

Power Sectors

- Power Generation

- Oil & Gas

- Petrochemical

- Mechanical Engineering

- Shipbuilding