PfP Industries, LLC

Houston, Texas, United States

PfP Industries, LLC

!

Oilfield Chemicals, Equipment, & Clean Water Services Since 1996.

About PfP Industries, LLC

PfP is a world leader in the supply of Polyacrylamide (FR), Guar, Stimulation Chemicals, & related products. PFP has been servicing the hydraulic fracturing & oilfield completions industry for over 25 years.

PfP Industries strives to be an industry leader by embracing and employing the latest innovations in technology, and in so doing, all of our products are designed to be problem-solvers.

Description of Services

- Oil Field Chemicals

Specialty chemicals products have become invaluable solutions to problems for oil and gas wells during fracking. PfP Industries have designed specialty chemicals products that are produced to enhance the efficiency and production of these wells from acidizing to hydraulic fracturing.

At PfP industries, these specialty chemical products are prepared, stored, and mixed with utmost care to keep the well life cycle running smoothly and efficiently with reduced cost and greater returns.

As a specialty chemical products supplier, PfP Industries has fine-tuned field formulations and is ready for distribution during peak stimulation activity on-site. PfP Industries has risen to the challenge to fulfill obligations to regulatory agencies for specialty chemicals. In everyday business, product quality control, reliability, deliverability, and HSE compliance are top goals at PfP Industries.

PfP Industries has adopted a quality and productivity strategy in packaging and labeling as well as storage and shipment of the finished product. An added benefit is minimization of specialty chemical product waste at the wellsite. Because of this, PfP Industries has reduced chemical returns which results in more satisfied customers.

Specialty chemical products at PfP Industries include: Friction Reducers-Suspensions, Friction Reducers-Emulsions, Gelling Agents-Guar, Non-Emulsifiers, Scale Inhibitors, Crosslinkers, Breakers, Flowback Surfactant, Biocides, and Clay Control Agents. Each of these specialty chemical classes has at least 4 different products to choose from.

The most critical additive for getting the most performance out of the stimulation process is the Friction Reducer.

At PfP Industries Friction Reducer Suspensions and Emulsions are listed under the trade name POLYglide Series. These specialty chemicals are used to provide consistent, reliable, and smooth performance during slickwater well stimulations. These products are used to reduce turbulent flow during pumping operations allowing frac to create fissures and place sand in less time and with less power.

Gelling Agents such as Guar, from the POLYfrac series of specialty chemical products is a gelling agent that is an essential additive in today’s hydraulic fracturing processes and can be found at PfP Industries. Guar gum is a water soluble, non-ionic polysaccharide produced from the seed of the guar plant that is native to India and Pakistan. Guar is added to water to create a suspension slurry or thickening agent to build viscosity and, ultimately, helps keep proppant in suspension long enough for it to reach its intended target deep within the fissures in the rock.

Another specialty chemical product at PfP Industries is Non-Emulsifiers from the POLYstim series that are used to break down emulsions which prevent oil and water from mixing. The main purpose of this non-emulsification agent is to break up emulsion before the stimulated well is put back to production and to speed up the separation of water and oil from the initial well flow-back fluid.

A specialty chemical product from the POLYstim series at PfP Industries is Scale Inhibitor which is used to prevent the formation of scale from blocking or obstructing fluid flow in the water systems through valves, pumps and pipelines used in production gathering, and processing. PfP's Scale Inhibitor is a specialty chemical product that will adhere to the interior surface of the system components to delay and prevent scale deposition.

At PfP Industries, Crosslinkers are available as four different POLYlink products and used to maximize fluid viscosity and proppant transportation at lower stimulation rates. This chemical is mixed with guar to create a viscous gel to be used in stimulation or pipeline cleaning treatments. The Crosslinkers products can help lower treatment and restimulation costs.

Breakers are a specialty chemical that ‘break’ the crosslinked frac fluid, reducing the fluid viscosity and allowing easier cleanup after the treatment. PfP Industries includes these products in the POLYbreak Series and incorporates sodium perborate and ammonium persulfate along with Omega-3 and Omega-11. These breakers can be used in hydraulic fracturing applications, at the end of jobs, and during flushes.

Flowback Surfactants are an important group of specialty chemical products offered by PfP Industries from the FOSSILflow Series. They are used to enhance fluid recovery after fracturing and are key to optimizing treatment fluid recovery, prevent down-hole emulsions, and to improve IP and long-term production after fracturing. These Flowback Surfactants help prevent water blocks and perform well in fresh water while being compatible with most fracturing fluid products.

Biocides are a specialty chemical product found at PfP Industries that kill bacteria. These Biocides can be used to control sulfate-reducing bacteria, slime-forming bacteria, iron-oxidizing bacteria and bacteria that attack polymers in fracture and secondary recovery fluids. The POLYcide series chemical effectively treats bacterial metabolisms such as acids, scales, slime and poisonous gases.

When reactive clays are present, swelling, dispersion, and migration can have a negative influence on production. PfP Industries can provide clay control agents from the POLYstim Series that can prevent the migration or swelling of these clay particles in reaction to water-base fluid. The clay control stabilizers are used in oil and gas wells for workover and intervention operations.

At PfP Industries there are many options when working to improve stimulation and efficiency of oil and gas wells. Our chemistry experts can help identify reasons for flow impairment and recommend the most cost effective logical specialty Hi chemical products to solve production issues and maximize return on investment.

- Stimulation Chemicals

PfP Industries strives to be an industry leader by embracing and employing the latest innovations in technology, and in so doing, all of our products are designed to be problem-solvers. Our Stimulation Chemicals product line provides a wide range of fracturing chemicals to help keep your business running smoothly and effectively.

Use of Stimulation chemicals

In the past, fracking has escalated. This practice allows for production in an even wider, more varying array of locations. It has also required oilfield chemical manufacturers to provide more selected Stimulation solutions.

These Stimulation Chemicals can be used in fracturing, re-frac, hot oil applications, acid stimulation, disperse asphaltene, and paraffin to remove the near wellbore damage and increase the oil production.

Extensive Range of Products

Oilfield stimulation chemicals include an extensive range of specialty chemicals intended to augment and support the stimulation process. PfP Industries has a broad selection of manufactured stimulation solutions that can restore or improve the productivity of a well. Better recovery of oil and gas from the targeted formation is a result of the improvement in the productivity of the new flow channels in the well. The PfP Industries specialty chemicals support and enhance the stimulation process, increasing the flow of oil and gas.

Upstream Chemicals

Oilfield stimulation is the process of upgrading the oil wells for the purpose of increasing oil production and increasing the flow of hydrocarbons. Chemicals used in the process of oil and gas well intervention are oilfield stimulation chemicals. PfP Industries can deliver a complete line of products and services to the upstream section of the well.

Products like acids and biocides are used to control the bacteria present in the fracturing fluid at the surface. Corrosion inhibitors are frequently needed in highly acidic and saline environments in order to protect the metal equipment. Friction pressure is a concern during the pumping process and can be efficiently managed by using friction inhibitors. The viscosity of fluids can be controlled by using gelling agents.

Oilfield Chemicals List of Products

With the development of new technologies and innovative chemicals, stimulation has now become an easy process. PfP Industries has a complete and comprehensive selection of Stimulation Chemicals for every oilfield well stimulation challenge. You can choose from proven products that include friction reducers, crosslinkers, breakers, scale inhibitors, biocides, surfactants, and guar gelling agents.

Our specialty products include Friction Reducers in dry, emulsions, and suspensions. We also produce and distribute gelling agent Guar. In the POLYstim Series, we carry Non-emulsifiers and Scale Inhibitors. Other products include Crosslinkers, Breakers, Flowback Surfactants, Biocides, and Clay Control Agents. Our group of specialty products, along with our professional customer service are mixed and maintained at a high level to ensure superior quality.

- Friction Reducer

In order to make the best use of your operations you need a fracturing fluid chemical that minimizes fluid friction pressure. PfP Industries offers a variety of Friction Reducers-Suspensions through their POLYGlide series. These products are specifically designed to deliver lower pumping pressures using less product in less time. PfP Industries provide these friction reducers for all fracture fluid types, from fresh water to brines, enabling flexibility in water management.

Fracking fluid or hydraulic fracturing fluid is composed of primarily water that is mixed with sand and then combined with a few additives such as a friction suspension that improves the fluid’s performance. The proppant, or sand, keeps the small fissures that are created by the hydraulic fracturing operation from collapsing when the oil well moves into the production stage. Pumping this mixture, or slurry, down into the wellbore generates friction between the fracking fluid and the well’s piping. Wear and tear on the pumps and other drilling equipment is increased when friction occurs. Friction suspension additives from PfP Industries are crucial to well stimulation performance.

PfP Industries provide chemicals to fracturing operations that need large amounts of water, which is then pumped at a high pressure to make fracture shales successful. Water is then treated with these friction-reducing additives to reduce the loss of pressure from frictional forces such as dirt and sand.

Friction suspension reducers are calculated to reduce the friction in the wellbore during the drilling and stimulation processes in unconventional reservoirs in the same manner with coal beds and shales. The large volumes of water pumped, and high rates, result in high friction pressures from turbulent fluid flow. This is why a chemical such as a friction suspension reducer is needed.

Friction reducers from PfP Industries are intended to help make the hydraulic fracturing fluid slicker. This process is sometimes named “slickwater” for the entire process. Polyacrylamide, a water-soluble polymer, is added to the friction suspension to help reduce friction and boosts the viscosity of the hydraulic fluid. The reduced friction increases pump efficiency, and the increased viscosity helps keep the proppant in suspension and evenly distributed throughout the fluid.

When large volumes of water are pumped, and high rates are required, this results in high friction pressures from turbulent fluid flow. Using water alone does not give the needed results. Cationic or anionic friction suspension chemicals, like PfP Industries provides, help to reduce turbulence and lessen friction losses.

In many applications, the water is not gelled and the roughness caused by the high flow rates results in high frictional pressure in the wellbore. A small amount of friction suspension is usually added to the water to reduce frictional forces, and its viscosity usually drops. PfP Industries is committed to helping keep production at the highest level possible.

Delivering huge amounts - 60 to 100 barrels - of fracturing fluid at extremely high pressure through a wellbore thousands of feet deep below the surface presents many challenges when doing a slickwater well stimulation. The goal is to hydraulically fracture the underground rock where the oil and natural gas are trapped. Friction Suspension reducer from PfP Industries can help generate viscosity with proper loadings.

While it is challenging, PfP Industries friction suspension can be functional in most climate types. Although friction reducer chemicals can freeze in colder weather, the weight and type of oil can help to determine the pour point of the friction suspension. The experts at PfP Industries can assist in finding the correct chemical needed.

PfP Industries friction suspension chemicals can benefit hydraulic fracturing with quick inversion, significant cost savings and less product per stage. It can also tolerate brine formulations and is simple to operate. These friction suspension chemicals in the POLYglide series from PfP Industries creates a smaller onsite footprint and enhances safety onsite.

By providing fricions suspension chemicals to oil and gas companies, PfP Industries is helping to conserve, reuse and recycle water.

- Oilfield Equipment

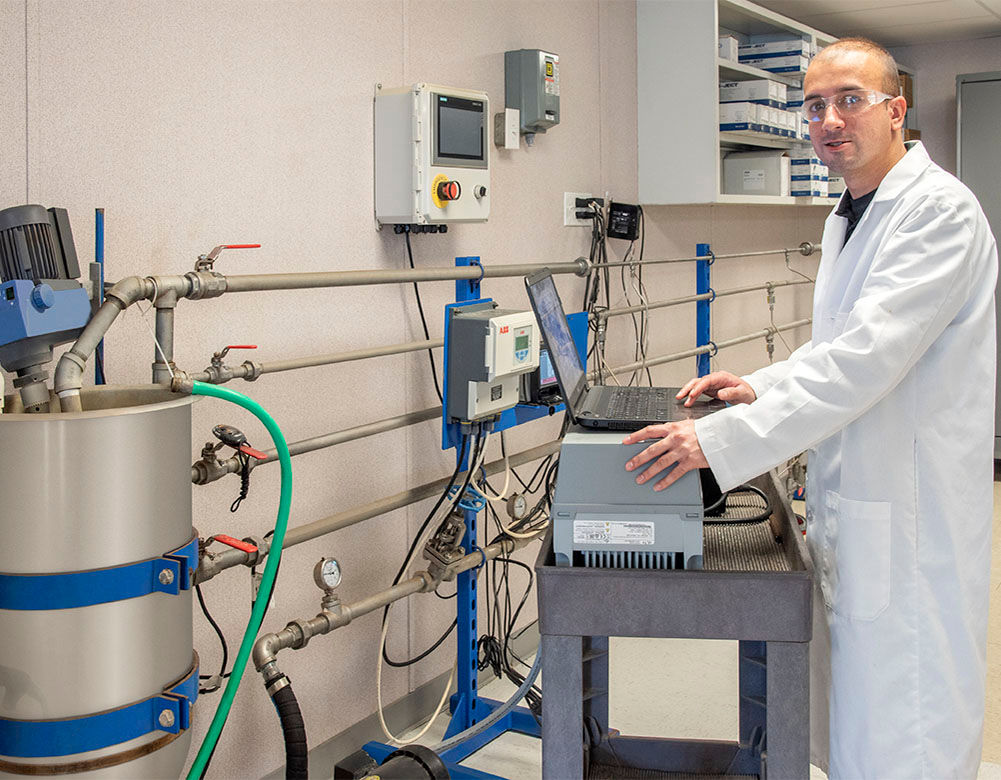

We have spent significant resources on R&D for the designing and manufacturing of patented equipment solutions for both Dry and Liquid FR's, Dry Guar and other liquid additives.

Oil Field Equipment

PfP Industries strives to be an industry leader by embracing and employing the latest innovations in technology, and in so doing, all of our products are designed to be problem-solvers. Our Oil Field Equipment Line provides rugged equipment units that perform a variety of special applications for blending and bulk handling of stimulation chemicals and can be delivered straight to you.

Wet or Dry Materials

Whether you are working with wet or dry materials, PfP Industries has equipment for both, and our units are designed in-house by our own innovative teams to ensure they are high performance, built to last, and designed to withstand all conditions.

NextGen FR-EZ Dual system

PfP Industries offers the NextGen FR-EZ Dual system that integrates two complete mixing systems in a single unit. This high-speed mixing service can be used in oil and gas drilling and completion operations. It is designed for efficiency, safety, and environmental requirements. NextGen FR-EZ is a portable mixing system that consists of two high-speed mixing pumps designed to deliver stimulation chemicals at once or can be used as a backup or as an independent mixing system. It is fully integrated with third-party equipment, has an 8’x12’ footprint, and has a 22 lb. /minimum delivery per side. It also has a 3500 lb. bulk container on each side and is fully electric. The NextGen FR-EZ can be combined with an external boost skid.

POLYMXR™ FR-EZ BOOST SKID

PfP Industries offers the POLYMXR™ FR-EZ BOOST SKID. This Dual FR-EZ system also integrates two complete mixing systems in a single unit. The second mixing system can be used as a backup or as independent mixing systems capable of running two different products at once. It is used to help companies solve process issues while improving efficiency and helps in creating an efficient custom skid solution that eliminates the need for re-work. The POLYMXR™ FR-EZ BOOST SKID can boost the dry FR-EZ discharge to the missile with a maximum rate of 180 gpm and a maximum discharge pressure of 150 psi using a discharge connection of 1x - 2” fig 200 thread. Suction is required at 4” fig 200 wings times 4 and fresh water supply is required. Power requirement is 480v 3ph, 60a stead, 100a surge (100kw gen to run FR-EZ with this boost skid). The dimensions are 6’ x 12’, and 5000 lbs. The discharge flow rate is available via various com protocols and the unit can also be used as a standalone metering pump.

FR Solution

BCU PUMP SKID OVERVIEW

The five key features to look for in deciding the proper slurry pump are slurry pump design, pump construction material, slurry pump deployment, and correct slurry pump power sizing. PfP Industries has designed the BCU Pump Skid to meet all these requirements. It is a self-contained pump unit for FR Slurries and the discharge of FR slurry is metered to the fleet equipment. The BCU PUMP SKID can recirculate slurry in a bulk container and the operational data is available to stream to the Datavan. The pump unit can also be mounted directly to an ISO or placed on the ground for easy access.

SYSTEM SPECIFICATIONS OF BCU PUMP SKID

The specifications for the BCU Pump Skid include an on board diesel generator with a progressive cavity pump that includes a 5HP electric motor. It has automated transfer and recirculation modes. Flowing conditions in the pump skid are controlled by a Coriolois flow meter. There is an optional bulk tank heater available for cold climates and is available to read in blender clean rates. The dimensions of the BCU Pump Skid are 38”W x 51”H x 78”L and is 2200 lbs. It also has a metered discharge ranging betwee 0.25 gpt@80 bpm to 8 gpt@100.

POLYMXR Unit - Dry Guar Solution

The POLYMXR Unit provides and performs dry guar solution at the well site. The POLYMXR Unit designed by PfP Industries can batch the gel on the fly at approximately a 4:1 concentration and the gel is fully hydrated when discharged. A hydration unit is not required. Also, a pneumatic bulk trailer is used to refill the onboard hopper. The clean rate is monitored live and the discharge rate is adjusted to maintain system loading. System loading can be remotely entered as well. Loading changes are instantaneous and system variables can be broadcast to the data van for live viewing with the POLYMXR Unit. It has fully automated controls, and is powered by a CAT C7.1 diesel engine. The load cells are used to measure the quantity of dry material for each batch and is introduced into the mixing stream via a hootonanny or eductor.

Here to Serve You

Repair and Maintenance

The experts at PfP Industries inspect, calibrate, and test each unit before deployment to ensure smooth operation. We will provide trained personnel to work alongside your team 24/7. We even provide on-site repair and maintenance to reduce downtime.

Delivery and Leasing

PfP Industries will bring our equipment to your site so that you can use it on your schedule. In addition, leasing our equipment reduces your environmental footprint.

Mobile and Quick

PfP Industries serves customers across the nation. Our equipment may be leveraged by any industry with large scale mixing needs, from oil and gas to agricultural operations. Our units are mobile and can be deployed quickly to any location. They get the job done.

- Water Clean-up Systems

We recognize the importance and necessity to do our part in water clean-up systems, and we have developed proprietary processes and equipment to conduct water clean-up projects.

PfP Industries' water management company, PRRO Water, offers sustainable and cost-effective water management solutions that address all types of water challenges across industries including oil and gas, chemical, mining, industrial, agricultural, and municipal waste.

- Iron

- SRB/APB

- Organics

- O&G

- H2S

- Ca, Mg, Ba, Sr,(multivalent cations-hardness)

- SO4, CO3, HCO3(anions)

- Boron

- Total Dissolved Solids(TDS)

- Total Suspended Solids(TSS)

- Integrated Management Packages

PRRO Water is committed to your project’s water management. From equipment considerations to blending, chemical treatment, and delivery, PRRO Water designs integrated management packages that give you peace of mind by meeting industry environmental standards and keeping your project on track.

Full Integration Into Your Project

We collaborate with your team to determine the best-fit for your deadlines, scope, and specialized application. Our business integrates the transport capabilities of our partner companies to create a one-stop solution for all of your water needs. We take the headache out of on-site treatment and haul away waste on your timeline.