Pipeline Integrity Solutions

Franklin, Louisiana, United States

Pipeline Integrity Solutions

!

Pigging Products, Isolation Gaskets, and Custom Solutions for Optimal Pipeline Performance.

About Pipeline Integrity Solutions

Drinkwater Products was established in Louisiana in 1987 by David and Judy Drinkwater. They found a niche in the oil & gas market to become a local source for pipeline maintenance products. Starting with serving local customers out of their garage, David & Judy found they could provide value by combining deep technical expertise with a great customer experience to provide the best solutions for their customers, quickly and affordably. Drinkwater Products has continued to remain family-owned and operated and has now grown to have two full-functioning offices, which service customers all over the world.

Our reputation makes us the number one source for the highest quality pipeline pigging products, Pikotek gaskets and other pipeline maintenance products. Our knowledgeable team is trusted by customers to guide them to the right pig for the job, get it to them on time and on budget, and help them build a maintenance program.

We’ve earned our reputation as independent, unbiased and experienced support for all our customers’ piping maintenance needs. Drinkwater Products strives to be recognized as the best at what we do: provide superior service, selection, speed and solutions.

Our Pipeline Experts Believe in Helping Clients to Create Comprehensive & Easily-Implemented Pipeline Maintenance Programs.

Description of Services

At Drinkwater Products, we constantly strive to deliver best-in-class specialty pipeline products to the oil and gas industry. Since 1987, we have been recognized as a leader in pipeline pigging products and services.

We have earned our reputation as the number one source for all pipeline maintenance products and services by working closely with our customers. Our pipeline experts believe in helping clients to create comprehensive and easily-implemented pipeline maintenance programs.

Our goal is to help ensure the integrity of the pipeline and to protect your operation from unexpected delays and downtime. In addition to providing state-of-the-art pipeline pigging products, we also offer the following services:

1) Pipeline Tracking Services

What is Pig Tracking?

Pig tracking is the process of monitoring the location of a pipeline pig as it moves through a pipeline. This crucial practice enables operators to quickly identify and address any issues, such as a stuck pig, which could pose operational risks and disrupt pipeline performance.

Tracking is applicable to most pig runs and nearly all pipeline systems. It is particularly critical in situations where there is a heightened risk of a pig becoming stuck—for instance, during the commissioning of a newly constructed pipeline or when working on lines that have been rarely or never pigged. Proactive tracking ensures smooth operations, reduces downtime, and enhances pipeline safety.

How does it work?

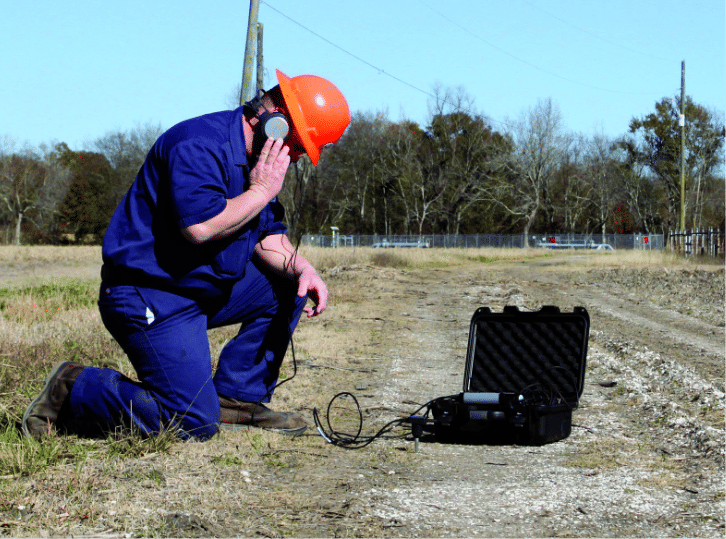

Pig tracking is generally done by a team who will intercept the pig at predetermined Above Ground Markers (AGM) and report its passage. Before most runs, a signal-emitting transmitter or magnet is placed inside the pig, which can be picked up above ground. The pig tracking teams will monitor the passage of the pig with receivers programmed to detect either the transmitter’s frequency or the change in magnetic field. As another measure of ensuring passage, these teams will listen for the pig with a geophone (acoustic amplifier system), which can allow them to hear the pig from up to 2 miles away.

Pig Tracking Services from Drinkwater Products

- The process of pig tracking begins with site selection or a site survey and identifying above ground markers (AGMs).

- Our crew will monitor the pig’s location throughout the run and provide updates on this progress to any necessary personnel.

- After the run is completed, we will offer a complete run report record with AGM locations, distance, pig speed and passage times.

- Our crews also have the necessary skills and experience to stake out future dig sites.

- We package all of these services along with the tracking equipment into an all-inclusive package to make sure our customers have nothing to worry about besides launching and receiving the pig.

- Speak to Drinkwater Products about our customizable or turnkey pig tracking service to meet your specific needs.

2) Pig Cleaning Services

Do you have a dirty pipeline pig that you don’t want to mess with? Drinkwater Products will now clean and rebuild your steel body pigs, so you don’t have to deal with the mess and save you time. The regular cleaning of your pipeline pigs extends the life of your pig by removing harmful pipeline debris from the pig itself.

We offer a full turnkey service which includes pick up/delivery, disposal of old parts, cleaning of pig body and reassembly with brand new parts. Call us today for a quote on pig cleaning. Call us today for a quote on pig cleaning.

3) GPT Flange Isolation Training

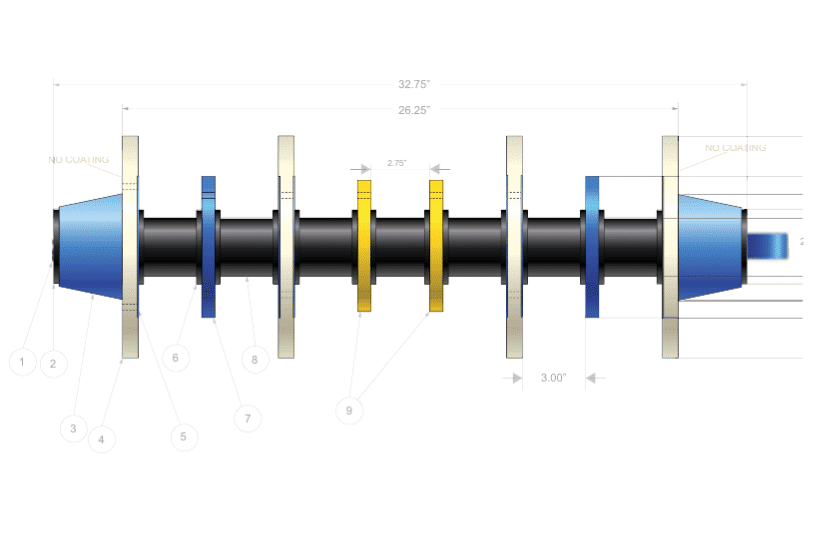

Introducing GPT Flange Isolation Training (GFIT), the world’s first dedicated training program for flange isolation. GFIT offers participants an in-depth 4-hour session on proper installation techniques for flange isolation kits (FIKs), for field installers and engineers.

GPT will train your installers and engineers to correctly install an isolating gasket and explain the critical role of each component required to successfully isolate the flanges for proper corrosion prevention of the system.

In addition, participants will receive hands-on installation training and will learn proper techniques using the correct test meters to accurately check for isolation of the gasket and flanges post installation.

Industry Challenges - Why Should I Participate

According to industry failure analysis, more than 80% of all gasket failures are due to incorrect user installation. These installation failures can be avoided with proper training and installation procedures.

Why GFIT?

- Many installation programs are available today that teach you how to properly install a gasket, but what do you do when your application requires the flanges to be isolated?

- In addition to proper gasket installation procedures, this training program goes above and beyond other programs to provide in-depth training on what additional components and techniques are required to properly isolate your flange connections.

- Whether you’re field-based or office-based, we offer tailored training programs to maximize your knowledge and understanding of proper installation methods and flange isolation techniques. This can provide an effective means of bridging the gap between onsite field technicians and engineering groups.

- Qualified GPT Installer Accreditation

- CEU Credits Applicable for Professional Engineers

Who Should Attend?

The GFIT training program is designed for Field Technicians, Integrity Engineers, Corrosion Engineers and those in general engineering roles. The training is designed for groups of 10 or more persons.

What will I learn?

- Safe procedures for installation and testing

- Why an isolating gasket is different than a traditional gasket

- Which tools to use and not to use in electrically testing isolation

- The correct process for installation of a kit

- How to inspect the flange and kit

- Typical modes of failure of a kit and how to avoid

4) Custom Design

There are many factors to consider when pigging pipelines such as product type, volumes, bend radii and much more. These variables will dictate what type of pig is right for your job. Unfortunately, there isn’t a “one-size fits all” option when it comes to pipeline pigs and a new design is required to accomplish the requested pigging goals.

Drinkwater Products has the knowledge and expertise to design custom made pigs for a wide range of irregular piping scenarios. Whether it is modifying an existing pig or designing something brand new, we believe that attention to detail can make all the difference in having an effective pig run.

We have the ability to customize configurations, sizing, durometer, bolt hole circle patterns. We can also manufacture your pigs with any color combination of bodies and/or urethane for whatever reason you have in mind.

Custom Options

- Material Selection: Foam, Urethane, Neoprene, Nitrile, Chemical Resistant Urethane.

- Dual-Diameter and Multi-Diameter options available.

- Nose Options: Bullet Nose, Double Dish, Double Nose, Flat on both ends.

- Cleaning Options: Steel Brushes, Plastic Brushes, Urethane Blades, Metal Studs, Silicon Carbide.

- Tracking Options: Electromagnetic Transmitters, Acoustic Pingers, Radioactive Isotopes.

- Custom-designed pigs take thought and planning. Having your pipeline specs available will give us the needed information to properly design pigs that will be effective and safe to run. Please call us to discuss your unique pigging needs.

5) Maintenance Pigging Strategies

"What kind of pigs should I use?” “How often should I pig?” These are common questions related to maintaining a clean pipeline. Historically crude oil lines were often pigged more regularly than natural gas lines, but not anymore.

With more and more wet gas systems in play, sweeping liquids has become as critical as cleaning paraffin out of oil lines. No matter what kind of lines you are maintaining, an effective maintenance program starts with knowing your line and selecting the proper pig. Drinkwater Products will help you in this process and can lay out a recommended strategy based on over 25 years of maintenance pigging experience.

It's most important to track your pigs when there is a concern about a pig becoming stuck in the pipeline, which can occur during the commissioning of a newly constructed pipeline or when working on a line that has been infrequently pigged.

Maintenance Pigging Strategies from Drinkwater Products

- Free Consultation

- Will provide spreadsheet with pipeline data including pig to be used on each line.

- Pig Options - Foam, Cast-Urethane, Steel Mandrel, Spheres

- Cleaning Options - Steel Brushes, Pencil Brushes, Plastic Brushes, Urethane Blades, Metal Studs, Silicon Carbide

- The following information is helpful:

- Is this a new or old line?

- Length of line

- Pipe ID (Internal Diameter or Wall Thickness)

- Bend Radius

- Wyes and Fittings

- Type of Product

- Flow Rates

- Pressure during normal operations

- Has any debris been recovered while pigging?

6). Step-up Pigging Plans

Paraffin has been a problem for crude oil pipelines for many years. As the oil cools down, wax (paraffin) begins to fall out (cloud point) of the oil and starts to build up in the pipeline. This wax build up, if not properly maintained, can lead to complete blockage of the pipeline. If recognized in time, the wax can be removed prior to complete blockage utilizing a series of pigs.

Putting together a Step-Up Pigging Plan requires careful study and attention to detail to ensure the pigs don’t push out too much paraffin at once creating a plug. When necessary, Drinkwater Products will recommend using some type of chemical solvent in conjunction with the pigging plan. This will help to soften hard paraffin, thus making it easier to remove. If you have a crude oil line that is experiencing high pressure and are afraid of it plugging, call us and we will lay out an effective, safe strategy for cleaning your pipeline one pig at a time.

Drinkwater Products offers a Step-Up Pigging Plan, sometimes using chemical solvents, to safely and effectively remove wax buildup and prevent clogs.

Step-up Pigging Plans from Drinkwater Products

- Free consultation before, during and after program implementation.

- Diagnostics report showing effective Pipe ID.

- Pigging Proposal includes types of pigs, quantities, and order that they should be run.

What we do

Is Pipeline Maintenance Really Necessary?

If you don't maintain your pipeline, your pipeline will not operate at optimum efficiency and will eventually deteriorate due to corrosion.

Corrosion can weaken the integrity of a pipeline which can potentially make it unsafe. The risk of pipeline failure far exceeds the cost associated with proper pipeline maintenance. Proper pipeline maintenance will save you money and protect the public and environment. Don't worry! You're not alone and we're here to help!

Life at Pipeline Integrity Solutions

-

Our Mission

- Serve our team and our customers using our God-given talents and abilities to positively impact their work and their lives.

-

Our Values

- To be the industry’s most respected, effective and innovative pipeline integrity company.

Our Values

PASSION

We combine our enthusiasm and positive attitude with hard work to solve problems.

Whatever you do, work heartily, as for the Lord, and not for men. - Colossians 3:23

INTEGRITY

Always do the right thing, even when no one is watching.

For we are taking pains to do what is right, not only in the eyes of the Lord but also in the eyes of man. - 2 Corinthians 8:21

GROWTH

Finding new ways to move forward translates into growth for our products, our company and ourselves.

Forgetting what is behind and straining toward what is ahead, I press on toward the goal to win the prize for which God has called me heavenward in Christ Jesus. - Philippians 3:13-14

SERVICE

Treat fellow team members, suppliers, and customers the way you would want to be treated.

Do to others as you would have them do to you. - Luke 6:31