PrePad

Houston, Texas, United States

PrePad

!

To set the global standard for cost and time estimation in drilling and completions.

About PrePad

Founded in 2021 and headquartered in Calgary, Alberta, PrePad was born from a unique and timely opportunity, envisioned by co-founders Sean Hervo and Brandon Eidson. Sean, based in Calgary, and Brandon, in Boston, synergize a dynamic blend of expertise and vision.

Their journey initiated at Shell, where, as employees, they crafted, refined, and applied the minimum viable product (MVP) of PrePad, specifically tailored to meet Shell's requirements. This experience brought to light two pivotal insights: the synergy of their skill sets and the extensive applicability of their solution beyond Shell.

With support from their families and Shell, they ventured out to fully realize PrePad’s potential. Today, PrePad stands as a testament to its vision to establish the global standard for cost and time estimation in drilling and completions. Guided by their leadership, PrePad is on a steadfast path to becoming an industry benchmark.

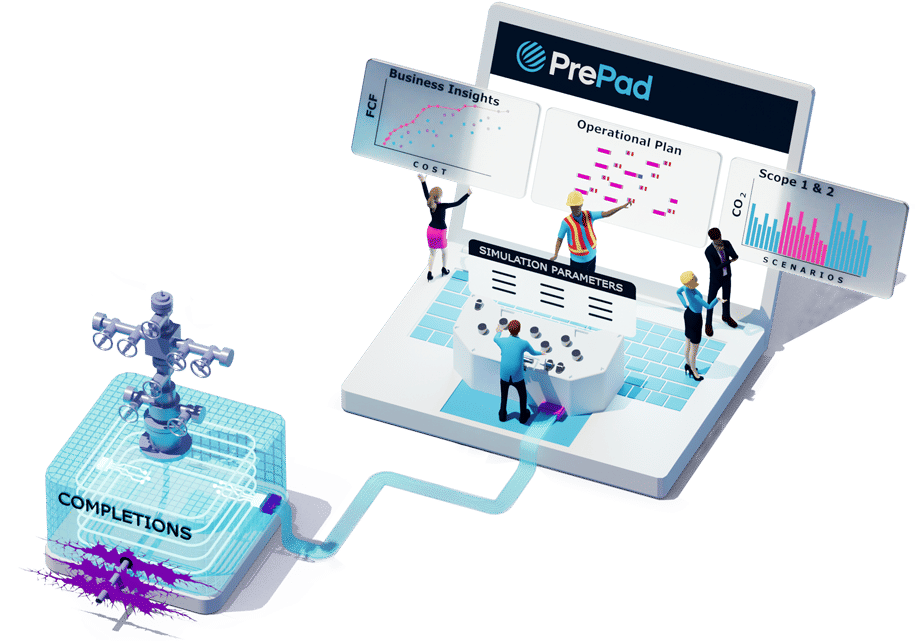

At PrePad, we don’t just create software—we’re on a mission to redefine the industry.

Our commitment is firmly rooted in our mission: to elevate engineering capabilities by revolutionizing drilling and completions, delivering sustainable, precise, and efficient cost and time estimation solutions.

PrePad isn’t merely our product—it’s our pledge to advance progress, efficiency, and precision in the energy industry, today and into the future.

Description of Services

SOLUTIONS:

1). Completions

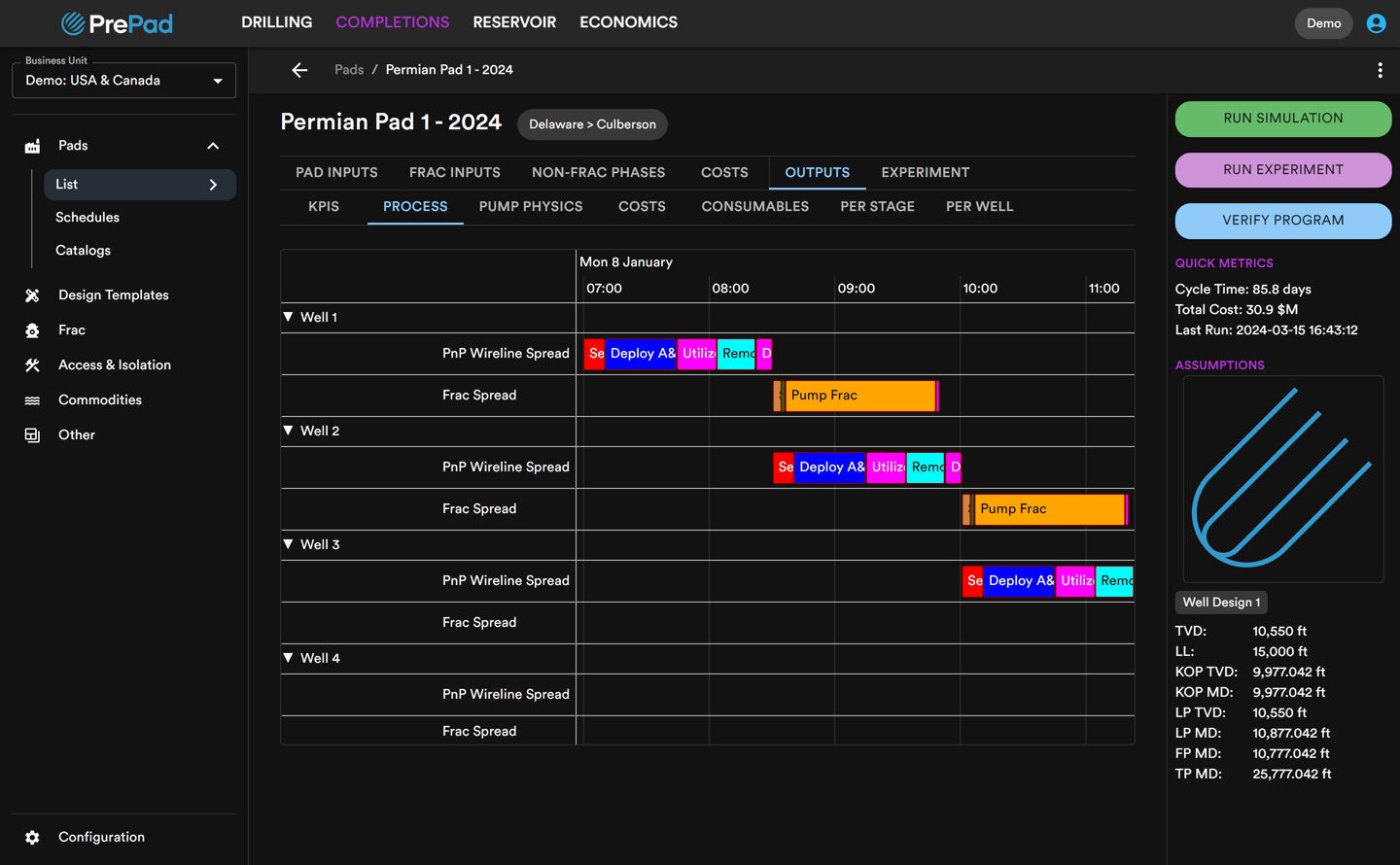

PrePad estimates and explains every dollar and every minute of every pad. PrePad's Completions module offers a multitude of benefits to energy producers, including:

- Generating accurate and transparent cost and time estimates for any design changes in minutes

- Decision support regarding contracting and supply chain strategies

- Minimizing the distraction of last-minute change requests effortlessly and accurately.

- Standardization across business units

- Knowledge retention and transfer

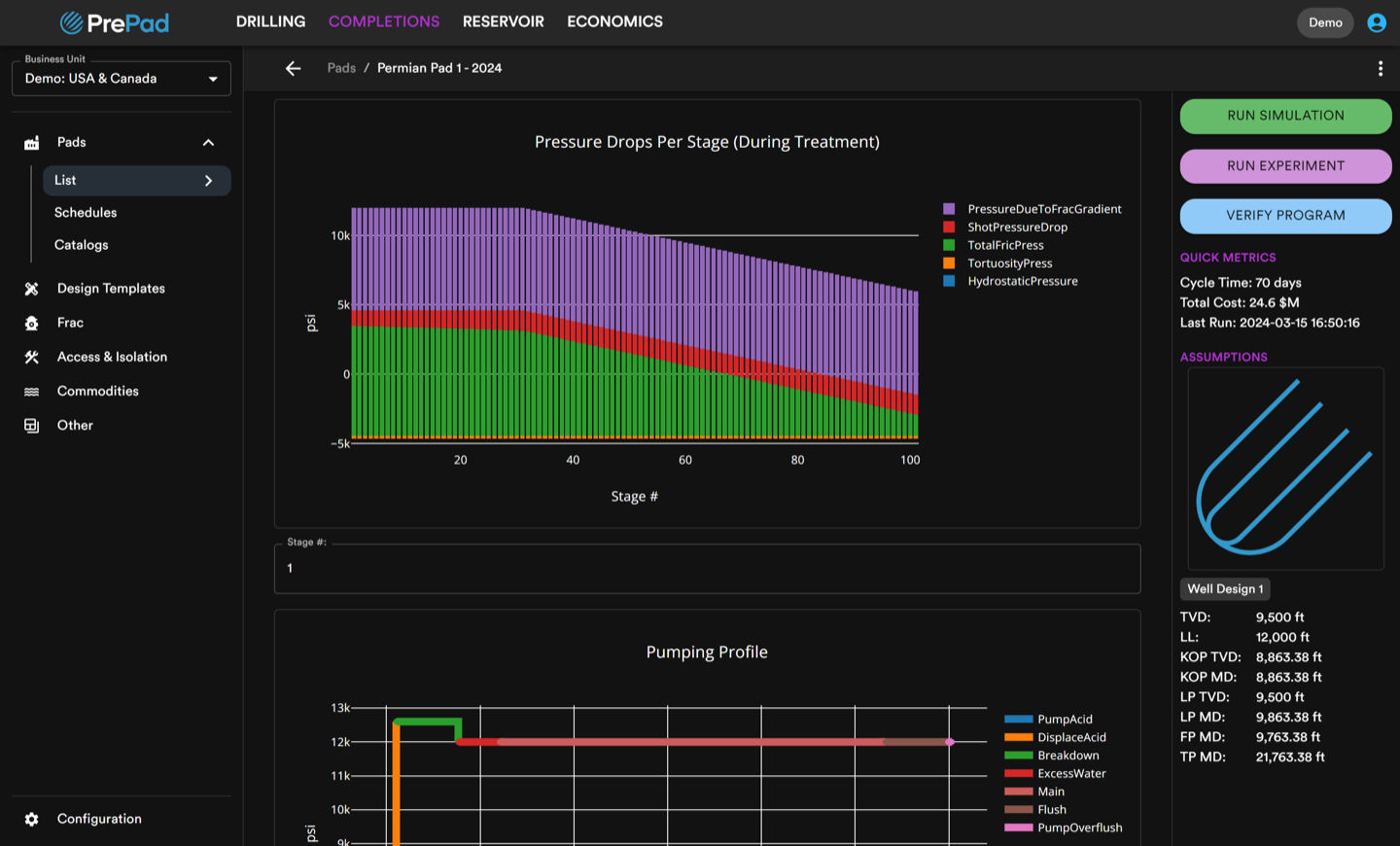

- Completions Simulation Model

Powerful, fully transparent algorithms estimate cost and cycle time by simulating the end-to-end process.

- Fully Transparent

Algorithms are not artificial intelligence or machine learning; they are transparent, authentic intelligence.

- Generate Completions AFE

AFE-level cost estimates with unique cost codes

- Experiment

Build a multi-variable design of experiments and simulate thousands of scenarios in minutes

- Demand Forecasting

Understand detailed demand forecasts and get ahead of potential bottlenecks.

2). Product Roadmap

Find out when new modules are expected to come online.

What we do

SOME CASE STUDIES:

1). Devon

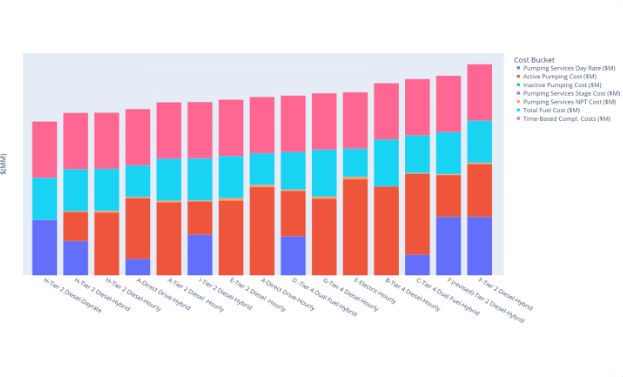

US Large-Cap Reduces Frac RFP Analysis Time From Several Weeks to Less Than a Day

Using 22 well pad designs and 9 unique frac efficiency values, Devon was able to quickly identify the optimal equipment and pricing structure from their 15 frac proposals.

Frac RFP Quantitative Analysis

In 2023, Devon included 15 different frac service company bids in their formal RFP with the aim of finding the best supplier for their specific frac needs. Each frac service provider had various equipment offerings and varying pricing structures, making proposal comparison a complicated and cumbersome task.

How PrePad Helped

Using 22 well pad designs and 9 unique frac efficiency values, Devon was able to simulate 2,970 different scenarios to quickly identify the optimal equipment and pricing structure from their 15 frac proposals. This scope of work, using legacy excel spreadsheets, would typically take Devon one month to complete. Once calibrated, PrePad provided the same information in less than a day.

2). Artis

Canadian Mid-Cap Increases 2-Year Free Cash Flow by $500,000 Per Well.

PrePad’s simulation software enabled Artis to estimate costs and cycle times with extraordinary speed and flexibility.

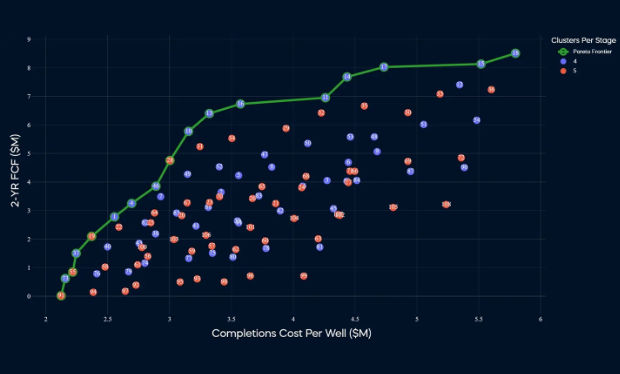

Understanding Trade-offs

Using PrePad’s simulation software, Artis was able to determine the trade-off between production, cost, and cycle time for several major design variables. These design variables studied included wells per pad, lateral length, stage spacing, sand loading, and fluid loading. The trade-offs were evaluated using the economic measure of 2-Year Before Tax Cashflow.

How PrePad Helped

To optimize Artis’s most important business metrics, PrePad simulated the end-to-end drilling and completions process for thousands of unique well designs. This simulation enabled Artis to quickly estimate costs and cycle times with extreme accuracy, which in turn allowed Artis to discover ways to increase 2-year free cash flow by $500,000 per well.

3). Shell Canada

PrePad Assists Multinational in Selecting the Most Optimal Completions Design

By running over 10 times more iterations than practical, Shell could identify where it makes sense to use plug and perf and single point entry completions designs.

Unlocking Immediate and Future Value Per Well

Shell partnered with PrePad to understand what frac cluster efficiency a plug-and-perf (PnP) well would require to breakeven with the single-point entry cemented sleeve scenario (at its optimal stage length). A comprehensive understanding of when to run each completion technology is essential for Shell to maximize the immediate and future value from their asset base.

How PrePad Helped

PrePad’s simulation software helped Shell understand the complex trade-offs and the interdependencies of variables such as well cost and time performance, contractual structure, and preferred financial metrics. By running over 10 times more iterations than practical due to highly manual and iterative tools currently available, Shell could identify where it makes sense to use plug and perf and single point entry completions designs, based on an assumed cluster efficiency for plug and perf.

Life at PrePad

PrePad enables oil and gas operators to discover the optimal trade-off between production, cost, cycle time, emissions, and risk by simulating the end-to-end well drilling and completions process for hundreds of unique designs in minutes.