RedHawk Coil Tubing

Kilgore, Texas, United States

RedHawk Coil Tubing

!

No one knows coiled tubing like RedHawk.

About RedHawk Coil Tubing

The group that started this company has successfully built multiple companies in the past. The Company started with the purchase of used assets. The units were completely disassembled and rebuilt in our own refurb facility. Since the first unit hit the ground, we have put out 4 more total units, with two new units coming for 2023.

We have also incorporated the use of real time data tools that utilize a specialized TEC line installed in our coil strings. We recently introduced a mixing plan and water clarification system into our service line.

Description of Services

- COILED TUBING

RedHawk Coil Tubing is led by industry experts, meaning your operation is in good hands. Our fleet is currently sitting at seven operational units (2 X 2-3/8” units, 4 X 2-5/8” and 1 X 1-1/4” unit), but plan to continue to expand RedHawk will also be adding ultra-deep CTUs into our growing fleet of equipment.

Our units have live data viewing capabilities through HAWKEYE. Each unit is equipped ESS and Slip-Mitigation to eliminate human error and reduce the chance of mechanical damage to the coil tubing. RedHawk is currently operational in ETX/NWLA, Oklahoma, South Texas, and West Texas.

We also have an exciting new piece of technology: TEC Line capable strings. This technology provides real-time downhole data and pushes it to HAWKEYE in conjunction with the surface data. To maximize our coiled tubing string life, we have implemented a specific pipe treatment program to ensure optimal performance and fatigue life of our strings.

Using a direct injection, low rate chemical additive pump, we have been able to mitigate the adverse effects of corrosion and corrosive gases that can lead to premature string failure. A corrosion analysis is performed on each string at the halfway point of its fatigue life, to ensure that the pipe treatment is continuing to work and no unknown damages have occurred. This has led to fewer pipe failures and allowed us to optimize our string life.

- FLUID PUMPING SERVICES

Our fluid pump fleet currently has 15 X 2,500HP frac pumps. We will be expanding our fluid pump lineup in 2023. Due to the extreme circulation pressures, we supply two frac pumps on location for standard coil tubing operations. Remote viewing of live flow rates, total liquid volume pumped, and pressures are visible in HAWKEYE.

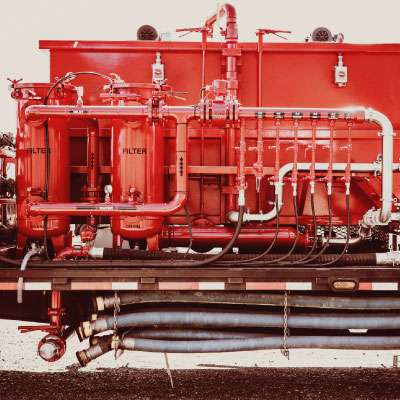

- MIXING PLANT SERVICES

The mixing plant uses automated chemical dosing of FR, HBFR Pipe-On-Pipe, Gel, H2S Scavenger, Corrosion Inhibitor. The flow rates are transmitted into to Hawkeye for remote viewing of the chemical data.

What we do

THE HARDEST WORKING CREW IN THE INDUSTRY.

INDUSTRY LEADERS DELIVERING DATA-DRIVEN DECISION-MAKING WITH RAPID INSIGHTS TO INCREASE PROFITS AND REDUCE INEFFICIENCIES FASTER THAN OUR COMPETITORS.

Our goal at RedHawk Coil Tubing is to provide you with the best people, service, and technology to exceed your expectations. We are proud of our Behavior-based Safety philosophy and strive to improve performance continuously. We understand that communication, preparation, and intelligent decisions are critical factors in achieving success.

Life at RedHawk Coil Tubing

EXPECT THE BEST PEOPLE, BEST EQUIPMENT, AND BEST SERVICE.

OUR MISSION

Our mission at Redhawk is to provide the best customer service and utilize technology and experience to optimize wellsite performance

OUR VISION

To become the safest and most efficient coil tubing provider in the oil and gas industry