SPECIALIZED DESANDERS USA

Midland, Texas, United States

SPECIALIZED DESANDERS USA

!

The future of sand management.

11-50 employeesAbout SPECIALIZED DESANDERS USA

Sand Management Solutions Since 2001

Our team of Engineers, Field Services and Business Development professionals are here to help you manage your most difficult sand challenges.

Specialized Desanders Inc. is a North American desanding solutions provider delivering unmatched service and products for over 20 years. We rent and sell horizontal and barrier desanders to customers in Canada, the USA, and through our international partners. We serve the oil and gas industry by equipping operators with proven equipment and data management solutions to tackle their toughest sand challenges.

Specialized Tech Inc. was established in 2001 and in 2014, the company rebranded to Specialized Desanders Inc., lead by Chris Hemstock, CEO. Over the years, we have expanded our footprint in Canada and the USA with locations in Alberta, Texas, Oklahoma, Pennsylvania, and Colorado.

We are committed to integrity, safety best practices, and relentless engineering. By providing patented and proven technology, we have earned our customers’ trust and industry acclaim by amassing over 20 desander patents and published case studies.

Specialized Desanders employs over 40 people in North America with a head office in Calgary, Alberta.

Description of Services

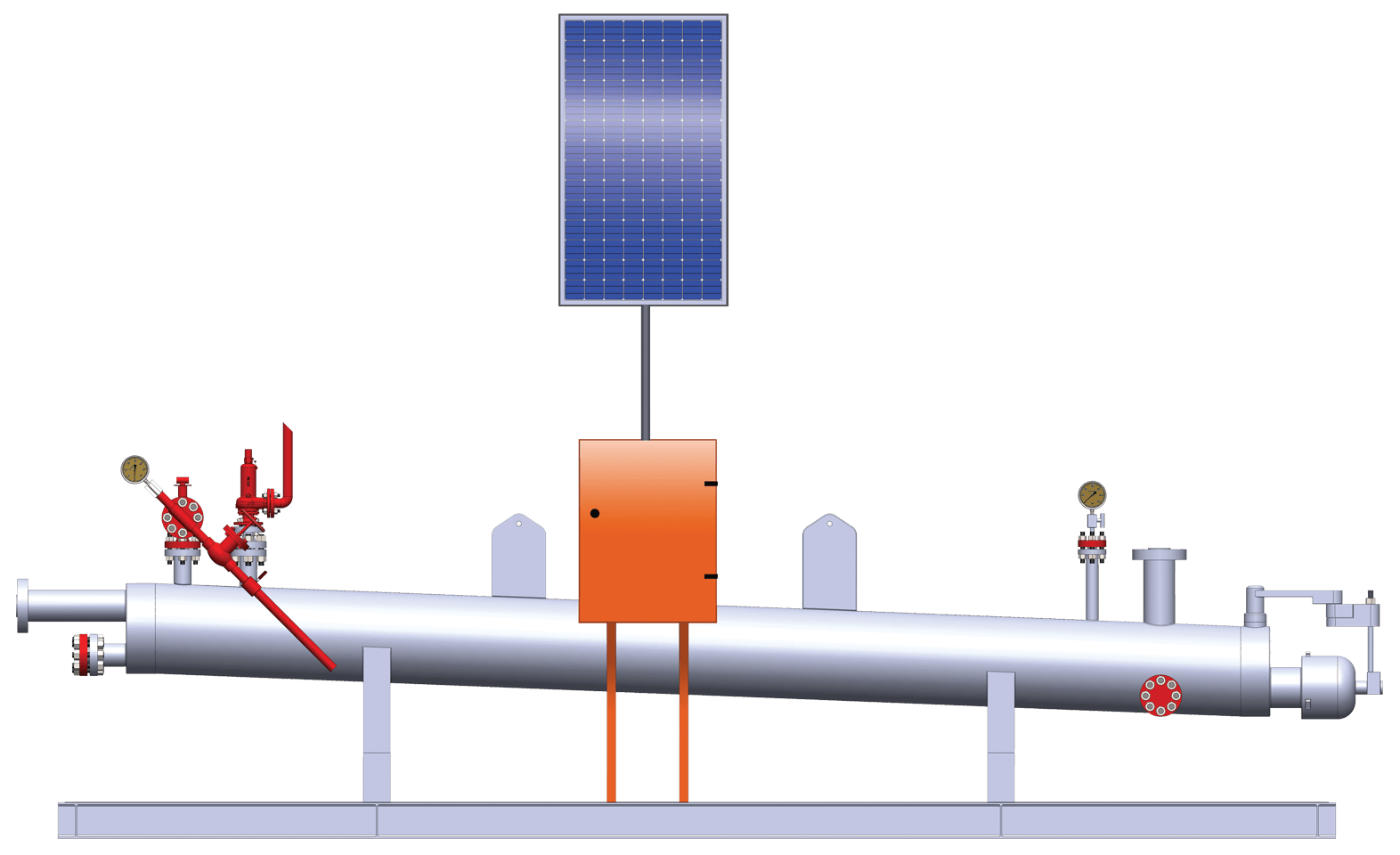

Sand Sentry Monitoring

The world’s 1st real-time sand production monitoring system.

Performance Highlights

- Local Display and Internet Access

- Allows Scheduling of Desander Cleanouts

- Monitor and Track Sand Production

- Monitor Remote Access Locations

- SMS or Email Alarm Notification

- No Unnecessary Cleanouts

- Solar Powered

a). Horizontal desanders:

Performance Highlights

Specialized Desanders function effectively over a broad range of flowrates. Sized to work with high initial rates, they are also able to handle the higher gas phase velocities that develop as production continues and flow pressures drop. This mechanism allows the same equipment to remain in service despite changing conditions.

- Pressure ratings 9930 kPa – 41, 370 kPa

- Temperature ratings -20 °F & -50 °F (Heated units available)

- Registered ASME, ABSA & National Board Certified

- Sweet & Sour Service Models

- Compatible with Sand Sentry™ Monitoring

- Eliminates Flaring

- No Pressure Drop

- Compact, Portable Size

- Easy Servicing & Minimal Clean Out Time

- Zero Emissions

- High Sand Capacity

- Manual and Closed Loop

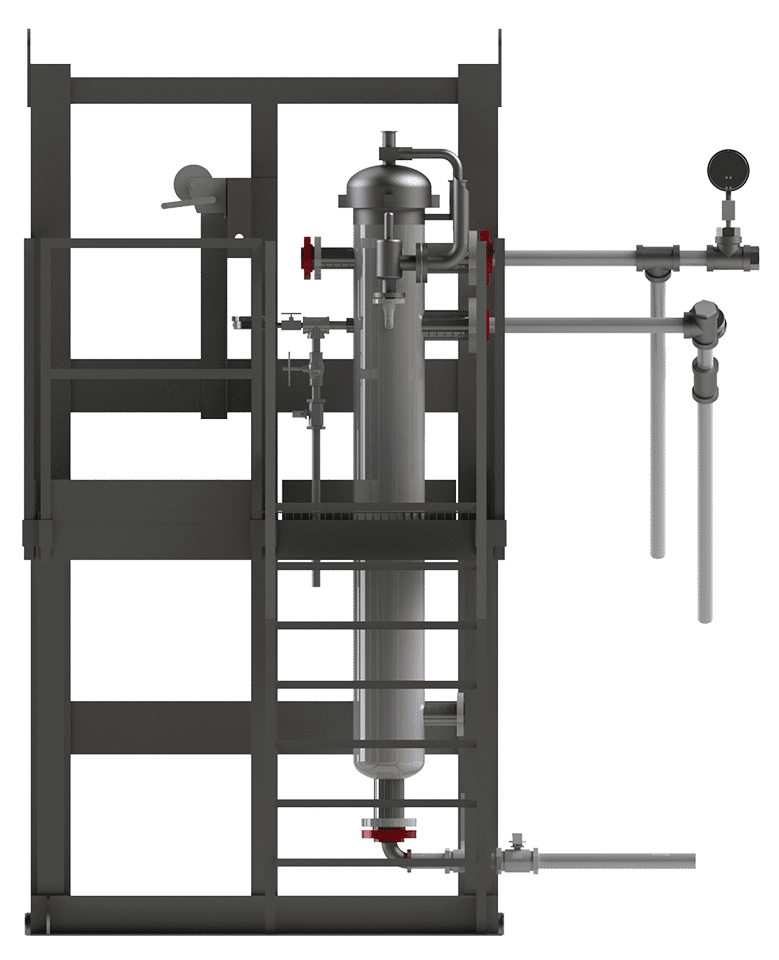

b). Barrier Desanders

- SynPOL Desanders

Shield your surface infrastructure from the hazards associated with particulate production using our durable barrier Desander.

Performance Highlights

- Differential pressure crush strength greater than 5,000 psi

- Temperatures to 400°F

- Pressure Rating up to 6,000 psi on the vessel

- Proprietary barrier available from sizes 100 to 200 micron

- Barrier Guaranteed Against Collapse

- Long-Term Sand Protection Solution

- Registered ASME, ABSA & National Board Certified

- Sweet & Sour Service Models

- Compatible with Sand Sentry™ Monitoring

- Eliminates Flaring

- Easy Cleanouts Using Flowback Flushing

- Compact, Portable Size

- Minimal Cleanout Time

- Zero Emissions Capable

- Warranty Against Collapse

- MiniPOL

A compact mighty solution for maximum sand capture on wells with a small footprint.

Performance Highlights

- 7’3” x 4’ x 4’

- No Collapse

- 100 to 200 Micron Capture

- 400F(200C) Maximum Plate Temperature

- Long Term Solution

- Sweet & Sour Service

- Sand Sentry Compatible

- Eliminates Flaring

- Simple Cleanout

- Compact

- Zero Emissions Capable

- Warranty Against Collapse

- MegaPOL

Our largest desander to date, made for high sand producing wells and maximum sand capacity.

Performance Highlights

- 5C (150F) MAWT

- 2350kg (5176 lbs) Sand Capacity

- 1322L (349gal) Liquid Capacity

- 8” tie in and out

- No Collapse

- 400F(200C) Maximum Plate Temperature

- Long Term Solution

- Sweet & Sour Service

- Sand Sentry Compatible

- Eliminates Flaring

- Manual or Automatic Cleanout

- Zero Emissions Capable

- Warranty Against Collapse

What we do

- What is sand control in oil and gas?

Sand control is a critical process in the oil and gas industry to manage and prevent the influx of sand or solids from the reservoir into the wellbore during production. When oil and gas are extracted, sand or other solid particles come up with the fluids. This can cause damage to equipment, reducing productivity, and potentially hindering the extraction process.

- How does SDI help flowback and production operations with sand control?

Our sand control equipment has logged millions of hours on North American well sites and provides our clients reliable and proven performance. Our gravity Desanding technology has several advantages versus competing technology (Spherical, Cyclonic, or filter designs) they include:

No moving parts, baffles or filters = Near zero differential pressure yielding Higher IP’s and far fewer components to get damaged or break or needing repair or replacement mid-job.

A proprietary design to lower the well stream’s velocity & turbulence = Unmatched predictable separation efficiency using physics (Stokes Law)

Vessels up to 24″ diameter and 20ft long, allowing maximum retention time = Separation of multiple sizes of particles and maximum solids capture.

The Sand Sentry sand detection system, the industry’s most accurate sand production evaluation tool = unmatched information & data, enables cost-reducing decisions in real-time.

All-inclusive pricing & support = Worry-free production and facilities integrity management.

Multiple locations throughout Canada & the USA = Coverage of any sized project in any basin.

We regularly conduct field studies and equipment tests and publicly share our case studies. Every interaction, every day, our employees conduct themselves with integrity that safely protects them, others, property, and the environment.

- What is the maximum sand holding capacity?

Our fleet of horizontal desanders have a solution for any well operation sand/liquid capacity. With our broad range of equipment in various sizes and pressure classes, we can hold up to 1,905kg/ 4,200 Pounds of sand before the units need to be cleaned.

- What is the difference between horizontal vs. cyclone desanders for sand control?

Our gravity desanding technology uses temporary phase separation and a significant reduction in velocity to safely remove the sand from multi-phase well production. The vessel’s barrel or the body does not have any baffles or plates to slow the flow down; this allows for near-zero pressure drop across our vessels. (<15 psi)

Cyclonic technology is designed to be most efficient in single phase & steady-state production; it significantly increases the velocity of the flow to force solid particles to the outer edge of the components. By forcing the well stream into a confined space and narrowing the flow path the resulting differential can be as high as 200psi-400psi (depending on the manufacturer and well flow characteristics) In reality once multi-phase production (Gas & Liquids) are introduced, the cyclonic action can breakdown and cause performance fluctuations that affect separation efficiency and differential pressure.

- What is the differential pressure?

<15psi?

- What is the maximum sand capture performance?

Our engineered design software allows us to simulate our performance pre-job to ensure success. We calculate all of our pre-job reports with a minimum design standard of 99%+ capture efficiency of 100 mesh (150 micron) solids. The flexibility of the gravity desanding technology allows the capture of solids larger and smaller than the design specs or the frac composition; this ensures unmatched separation efficiency results and maximum protection for surface facilities.

- How do you measure sand?

Sand Sentry is a web-based and on-site sand monitoring system. This software monitors sand production from oil and gas wells. Measurements are provided accurately to the pound or litre, not in approximate ranges. Access your data anytime, anywhere. Additionally, be notified by SMS or email when cleanouts are required. This system can be integrated into a well site SCADA system to automate shutdown protocol. It results in minimal downtime, saving you time and money.

- What does a monthly desander rental include?

Our monthly rate includes all monitoring and regular wear and tear; more importantly, our sand control equipment has no redress charges at the end of the install. Save uncertainty with our equipment design, expert quality, unmatched service quality, and customer support.

- Does SDI have sand control units in my area?

SDI has a large fleet of units in Canada and the USA. We have field locations in Beaverlodge and Three Hills Alberta. In the USA, we are located in Midland, TX, Pittsburgh, PA, Oklahoma City, OK and Denver, CO. We have been building and expanding our Desander fleet since 2001. Specialized Desanders has the equipment to make your project a success.

Life at SPECIALIZED DESANDERS USA

Specialized Desanders is a complete multiphase sand management and erosion control equipment provider. For almost 20 years, we have been engineering leading desander products for the North American and international oil and gas industry with a focus on best-in-class innovative solutions.

PATENTED & PROVEN

SDI Desanders are developed and tested by our experienced engineering team, earning us over 20 notable patents and industry research acclaim. Our equipment has logged millions of hours on North American well sites and provides our clients reliable and proven performance to combat the operation realities they face.

If your current desanding equipment isn’t getting the job done, consider a Horizontal or Barrier Desander.

MORE THAN SAVINGS

Sand passing through to your process equipment can have catastrophic costs and cause significant damage meaning more $ down the pipe. Operators have saved up to 55% on flowback costs and get to production desanding 40% sooner with SDI.

Eliminate unnecessary maintenance costs by getting it right the first time.

DATA THAT PUTS YOU IN CONTROL

Sand Sentry allows you to manage your well data remotely. Monitor sand capture and schedule clean-outs only when needed, lower methane exposure, and daily blowdowns. Our dashboard visualizes your data, providing you real-time, accurate information anytime, anywhere, on any device.

End the guessing game of sand management and have 100% data accuracy.

INDUSTRY BEST SAND CAPTURE

Desanders are engineered to keep you productive and reduce worry. You can be assured you have 99%+ of sand capture at the wellhead with SDI. With constant field study and equipment testing, we regularly evolve from industry evaluation. There is a good reason why we’re often copied but never duplicated.

Unsure? We have case studies and millions of hours logged to prove it.

BEYOND SAFETY AND BEST PRACTICES

SDI’s daily business is undertaken with the objective that at the end of the day, our employees will go home unharmed. Our employees conduct themselves with the integrity that protects themselves, others around them, property, and the environment while maintaining compliance with all applicable laws.

A successful Safety Management System requires the involvement of employees at all levels. Our competitive process defines the essential components and supports employees by having resources available to them for leading-edge equipment, training, and protective devices.