UP (United Pacific Projects Ltd.)

Calgary, Alberta, Canada

UP (United Pacific Projects Ltd.)

!

The next generation of Pipeline Inspection is here.

About UP (United Pacific Projects Ltd.)

United Pacific Projects is Driving Inline Inspection Innovation.

We create products that push the envelope of data quality, accuracy, and ease of deployment currently offered to the Inline Inspection Industry, while providing superior customer service and customized solutions.

Our Goal

United Pacific Inspection strives to be the industry leader in inline inspection (ILI) by delivering products that enhance data quality, accuracy, and ease of deployment. We prioritize exceptional customer service and offer customizable solutions to meet our clients’ unique needs.

Tools & Technology

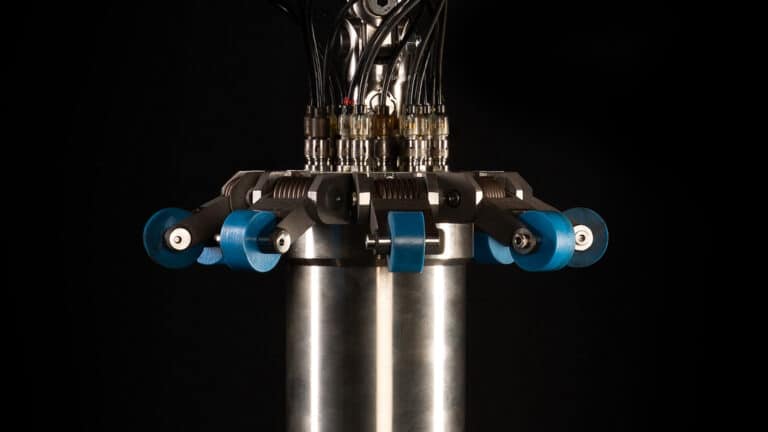

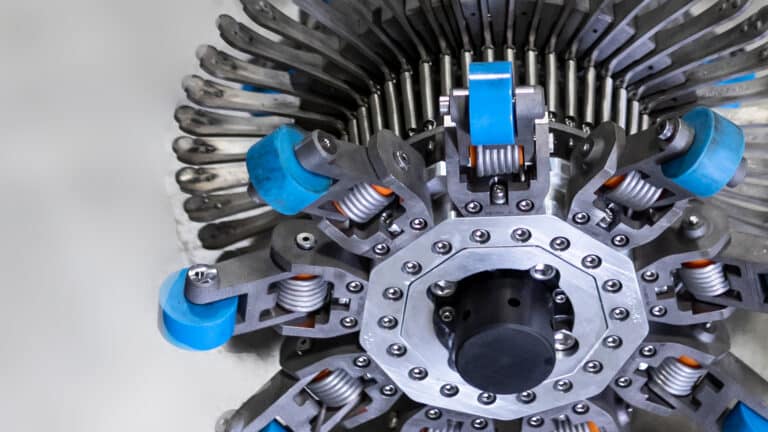

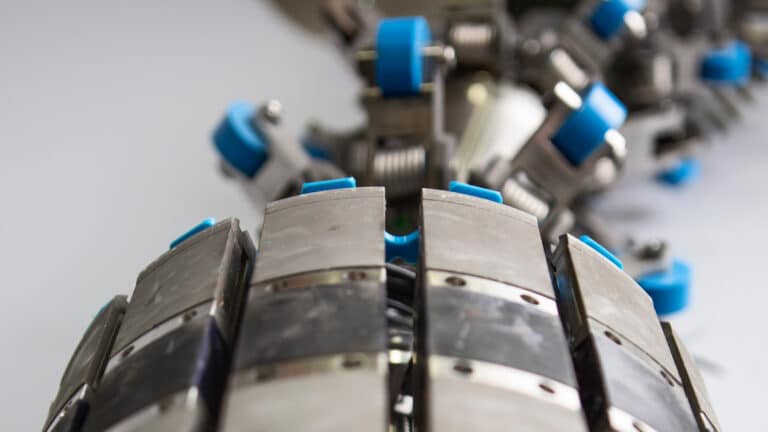

The Next Generation UPP ILI tool will utilize numerous complementary data sets to improve accuracy and ensure a full set of pipeline data is collected during one pass.

Description of Services

Inline Inspection Services:

1) Wireline (tethered) Pipeline Inline Inspection

If every pipeline system were the same, our job would get pretty monotonous.

Luckily, clients come to UPP with unique challenges that keep us on our toes.

UPP specializes in smart PIGS for pipeline inline inspection, but what happens when you encounter a pipeline system deemed “unpiggable”? These systems are tough to inspect using traditional methods because of complex shapes, low flow rates, or other factors that make regular tools ineffective. Fortunately, we have reliable solutions to help pig the unpiggable.

Tethered Pipeline Inline Inspection

Wire-line (tethered) inline inspection services are typically needed for pipelines which are challenging to pig due to a breach or dent. These systems may have sharp turns, varying diameters, or other obstacles preventing the use of free-swimming inspection tools.

Pipelines with low flow rates or those not in constant use may also require this specialized inspection method. Without proper inspection, issues like corrosion, cracks, or other damage might go unnoticed, potentially compromising the pipeline’s safety.

How does Tethered Pipeline Inspection Work?

Unlike free-swimming pigs that move with the pipeline’s flow, tethered tools are tethered via a wire-line, which allow our wireline trucks to pull our bi-directional UXD Inline Inspection Tool backwards.

The tether provides power and real-time communication, allowing data collection and analysis during the inspection. The data includes clear images and precise measurements, helping identify issues like corrosion, cracks, and metal loss.

Advantages of Wire-Line Inline Inspections

A major advantage of wire-line inspection is its ability to access difficult-to-reach pipelines. It can navigate tight turns, adjust to different diameters, and even move uphill or downhill.

This flexibility ensures a thorough inspection, reducing the risk of missed issues and giving operators accurate information to create detailed ILI reports that highlight the maintenance and repairs that should take place.

2) Magnetic Flux Leakage (MFL) Pipeline Inspection Services

MFL Pipeline Inspection Services

Magnetic Flux Leakage (MFL) was first developed in the mid-twentieth century as a non-destructive testing method. It has since become essential for the inline inspection of pipelines, storage tanks, and other steel structures prone to corrosion.

MFL uses the principles of electromagnetism to detect flaws in steel materials, which is crucial for ensuring pipeline integrity and the safety and strength of other structures. MFL has made huge advancements in precision and reliability over time, and it is now a widely used technique in non-destructive testing.

Common Applications for MFL Inspection

- Early Detection

Identify corrosion, pitting, and metal loss early to address issues before they escalate, protecting your infrastructure from costly failures. - Comprehensive Coverage

MFL inspects the entire pipeline circumference, ensuring thorough coverage. This approach detects even the smallest defects, particularly in high-risk areas like joints and submerged sections. - Real-Time Data Collection

Our system provides real-time data for immediate analysis and decision-making, crucial for both routine maintenance and emergencies. Make informed decisions based on the latest information, no matter the situation. -

UPP’s Approach

UPP’s inline inspection tools stand out with their multi-technology capabilities. Our MFL advancements, combined with Caliper (CAL) technology and Inertial Measurement Units (IMU), offer total effectiveness and cost efficiency.

We integrate these advanced tools with powerful in-line inspection (ILI) data analysis, producing detailed, actionable pipeline inspection reports. Our expert analysts provide insights that help you make well-informed decisions about maintenance, repairs, and future inspections.

3) Inline Inspection Services

What is Inline Inspection?

Inline inspection is essential for assessing the internal conditions of pipelines and plays a crucial role in pipeline integrity and maintenance programs. The process involves inspection points along the production line, ensuring products meet quality standards using specific gauges for each task.

A key tool in inline inspection is the Pipeline Inspection Gauge (PIG), often referred to as a “smart pig.” These devices are equipped with advanced sensors that detect anomalies like corrosion, cracks, dents, and other mechanical defects.

How does inline inspection work?

Inline inspection devices may contain multiple data collection modalities in a single pig. For example, UPP’s smart pigs are complex combo tools that can analyze several deficiencies simultaneously.

The key technologies for pipeline inline inspection include:

Full Tri-Axis MFL (Magnetic Flux Leakage): Detects and sizes metal loss anomalies.

CAL (Caliper) Technology: Measures pipeline geometry and detects dents and deformations.

Integrated IMU (Inertial Measurement Unit): Precisely maps pipeline coordinates and identifies alignment changes.

Why do companies conduct inline inspections?

Inline inspection tools enhance safety by detecting issues like cracks, corrosion, or metal loss, which can lead to leaks or pipeline bursts. Early detection allows for timely intervention, preventing environmental damage and protecting human lives. Additionally, proactive maintenance can prevent costly repairs and extend the pipeline’s lifespan.