Vacuum Barrier Corporation

Woburn, Massachusetts, United States

Vacuum Barrier Corporation

!

We design, engineer and fabricate LN2 dosing and piping systems for Food & Beverage, Semiconductor, MBE, Pharmaceutical, Biotech, Beer, Wine, Coffee, and Cannabis industries.

About Vacuum Barrier Corporation

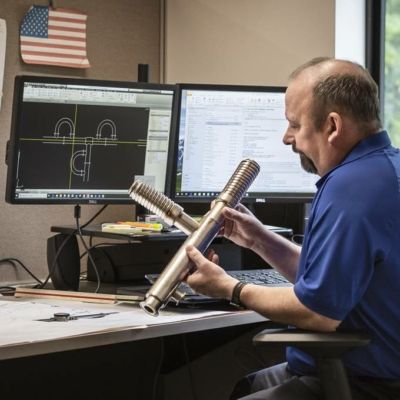

CRYOGENIC CRAFTSMEN

Vacuum Barrier Corporation designs, engineers and fabricates LN2 dosing and piping systems for Food & Beverage, Semiconductor, MBE, Pharmaceutical, Biotech, Beer, Wine, Coffee, and Cannabis industries. Investigating your application, we provide a custom or standard LN2 solution and become your one-source for a complete system.

Our continued commitment to delivering safe and defect-free products while achieving the highest customer satisfaction has allowed us to remain the leader in LN2 dosing and piping systems since 1958.

Description of Services

Industries we serve:

- Food & Beverage

- Semiconductor Wafer Growth

- MBE

- Pharmaceutical & Biotech

- Beer, Wine & Coffee

- Cannabis Flower/Cannabis Beverage

- Lighting

- Automotive

- Rubber Deflasking

- Environmental Chambers

- Special Effects

What we do

At Vacuum Barrier we design, engineer, and manufacture LN2 piping and dosing systems for various industries. We Investigate your unique application and provide a custom or standard LN2 solution to become your one-source for a complete system. Our commitment to delivering safe and defect-free products while achieving the highest customer satisfaction has allowed us to remain the leader in LN2 dosing and LN2 piping systems since 1958.

If you have an LN2 piping or dosing project you’d like to discuss with our expert team, please reach out today.

LN2 Dosing

Pressurizing thin-wall packages for handling or dissolving oxygen to extend shelf life can be achieved with a precise drop of liquid nitrogen. To pressurize, LN2 is dispensed into the package, vaporizes, and expands to fill the headspace forcing nitrogen into the solution and adding rigidity. To inert the headspace, the vapor is allowed to expand prior to sealing, pushing out oxygen and extending shelf life.

LN2 Piping

Vacuum Barrier’s vacuum jacketed dynamic and sealed SEMIFLEX LN2 pipe delivers LN2 in two-phase condition. Our liquid/vapor phase separators deliver low-pressure, single-phase LN2 to each use point for on-demand supply. Combining SEMIFLEX with Triax LN2 piping eliminates two-phase flow to use points.

LN2 Quality

It is our policy to understand and fully meet customers’ requirements at all stages of work. Our goal is to design, manufacture and deliver safe and defect-free products while achieving the highest customer satisfaction.

Life at Vacuum Barrier Corporation

Food & Beverage

VBC LN2 dosing systems pressurize thin-wall packages adding necessary rigidity for handling and transport. The same systems reduce oxygen in packages to extend product shelf life.

Semiconductor & MBE

SEMIFLEX® vacuum jacketed pipe and vapor vents ensure a constant supply of LN2 is maintained to multiple use points with minimal losses. For Epitaxy applications, a combination of modulating inlet phase separator and Triax piping ensures sub-cooled, single-phase LN2 circulates through the shroud.

Pharmaceutical & Biotech

SEMIFLEX®/Triax piping system delivers low-pressure LN2 critical for the cryogenic preservation of blood, reproductive cells, vaccines and other biological tissues and materials in storage freezers.

Beer, Wine & Coffee

VBC LN2 dosing systems are used in both beer and wine to purge oxygen from the headspace, preserving the flavor, aroma, and color. The same system nitrogenates beer and coffee to achieve the smooth, creamy cascade effect, with or without a widget.

Canned Wine

VBC LN2 dosing systems pressurize non or lightly carbonated beverages in cans to aid in transport and handling. Adding a drop of LN2 into the headspace provides the needed rigidity.

Cannabis

VBC LN2 dosing systems purge oxygen from the container to extend the shelf life of the active compounds in Cannabis.

Cannabis Beverage

VCB LN2 dosing systems pressurize lightweight PET bottles or cans for transport and handling. After filling, adding a drop of LN2 to the headspace adds the needed rigidity.

Pouch/Flexible Packaging

VBC LN2 dosing systems add rigidity to pouch/flexible packages for handling and transport. The same system reduces residual oxygen to extend shelf life.

Cooking Oils

VCB LN2 dosing systems eliminate bottle paneling. Cooking oils absorb oxygen in the headspace, reducing the bottle’s internal pressure and leading to bottle paneling. Adding a drop of LN2 at capping offsets potential paneling.