Wild Well

Houston, Texas, United States

Wild Well

!

Wild Well is the world’s leading provider of onshore and offshore well control emergency response, pressure control, relief well planning, engineering, and training services.

About Wild Well

Founded in 1975, Wild Well is the world’s leading provider of onshore and offshore well control emergency response, pressure control, relief well planning, engineering, and training services. Headquartered in Houston, Texas, and with offices in eight other major cities, Wild Well provides its services on a global basis and responds to an estimated 80% of the global well control response market. Wild Well has successfully capped hundreds of wells worldwide in all kinds of operational environments. Oil and gas operators rely on Wild Well’s experienced personnel for advanced engineering solutions, unconventional intervention, and well control training to prevent and safely resolve well control incidents.

Wild Well continues its tradition of being the global leader in emergency response, well control, subsea operations, and training by offering a range of services to meet the industry’s ever-changing needs. Whether offshore or onshore, Wild Well responds quickly with experienced personnel and customized equipment to maintain the integrity of a wellbore through the use of innovative engineering solutions.

Our Vision is to provide well control services to oil and gas operators by responding safely and efficiently to emergencies and operational challenges. Wild Well approaches each well control event from an engineering perspective and works to secure well integrity while protecting the operator’s investment. Wild Well delivers comprehensive prevention and preparedness planning to avoid future emergencies and is the leading provider of well control training.

Description of Services

Well Control Engineering

WELL CONTROL ENGINEERING OFFICE SUPPORT

Well Control Engineers can be deployed to a client’s office to assist the engineering staff and management team in developing diagnostic plans.

Well Control Engineering

WELL CONTROL ENGINEERING FIELD SUPPORT

Well Control Engineers can be deployed to field locations to help client personnel with on-site well control operations.

Modeling

Blowout Rate Modeling

Blowout rate modeling uses multiphase simulations to calculate the maximum expected flow rate from producible reservoirs or target formations for a given well and reservoir configuration.

Modeling

Dynamic Kill Analysis

Dynamic kill analysis offers a dynamic simulation of blowouts as well as operating parameters for the necessary kill process.

Modeling

Broaching Simulation & Analysis

Broaching simulation and analysis consist of evaluating a shut-in well’s behavior once pressure at the casing shoe exceeds the fracture gradient of the surrounding formation.

Bullheading Analysis

Bullheading analysis consists of multiphase simulation and analysis of the well control parameters (e.g., pressure, density, pump rate, etc.) required to successfully bullhead a well.

Modeling

Dynamic Temperature Modeling

Dynamic temperature modeling simulates the dynamic temperatures that a rig’s well control systems could potentially encounter during kick circulation.

Modeling

Shut-in Analysis

Shut-in analysis determines the maximum pressure in a well when considering shutting it down using a capping stack. It helps mitigate the risks associated with hard vs. soft shut-in methods.

Modeling

Real-Time Support for Critical Well Operations

Working from the office or on-site as part of the drilling team, Well Control Engineers are available to provide real-time well control expertise and engineering support during critical well operations.

Modeling

Surge/Swab Modeling

In HPHT wells with small margins, it is critical to maintaining circulation during swabbing operations to avoid underbalanced conditions.

Modeling

Thermal Expansion Modeling

During well kill operations, thermal expansion of the drilling fluid is suspected in masking the correct shut-in pressure values. To address this, Wild Well performs multiphase simulation-based analyses to determine the potential for thermal expansion issues for a given well

Modeling

Well Control Modeling

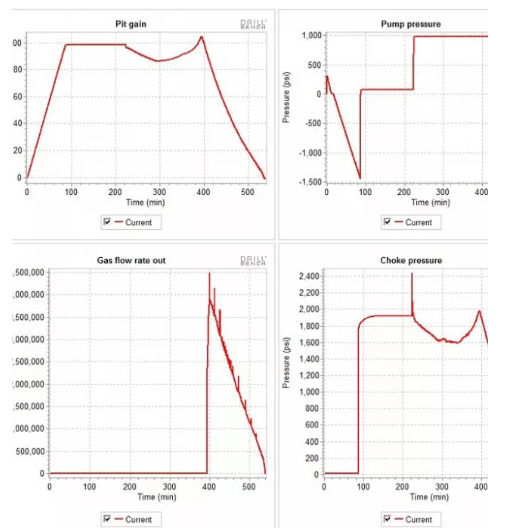

Wild Well uses Drillbench Rig site Kick software to generate integrated, time-transient, multiphase flow simulations to examine the total dynamic behavior of the wellbore and its contents from time of influx through flow check shut-in and subsequent kill operations.

Modeling

Well Control Risk Assessment

The well control risk assessment process involves identifying, evaluating, and ranking well control risks associated with drilling and intervention operations.

What we do

Engineering Analysis

Digital Twin

Digital twins are becoming more common throughout the energy industry as the use of enhanced technology, data availability and transmissibility continues to accelerate.

Engineering Analysis

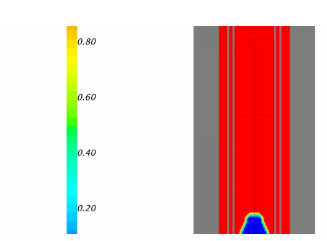

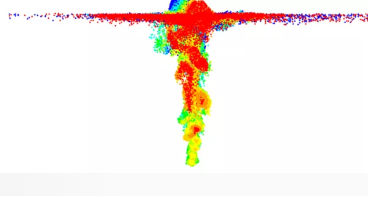

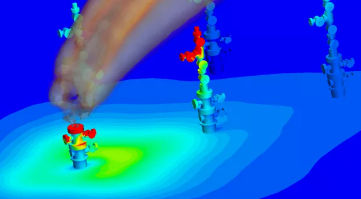

Subsea Dispersion (Plume) Analysis

Subsea dispersion (plume) analysis simulations model the behavior of oil and gas as they rise from the wellhead to the sea surface during a subsea blowout.

Engineering Analysis

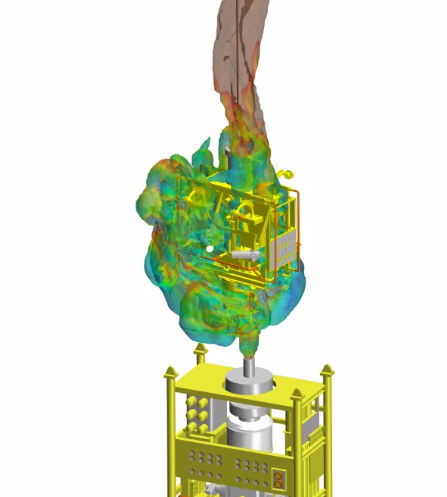

Atmospheric Dispersion Analysis

Atmospheric dispersion analysis uses calculations and/or simulations to predict the propagation of gas clouds from a blowout, leak, or flare.

Engineering Analysis

Radiant Heat Analysis

Radiant heat analysis uses calculations and/or simulations to determine the magnitude of radiant heat energy generated by a fire.

Engineering Analysis

Fire and Explosion Analysis

Explosion analysis offers studies of explosion severity should a gas cloud ignite. It is aimed at quantifying risk to personnel, equipment, and infrastructure.

Engineering Analysis

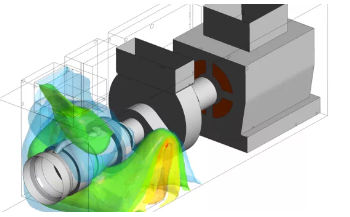

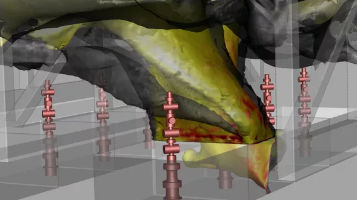

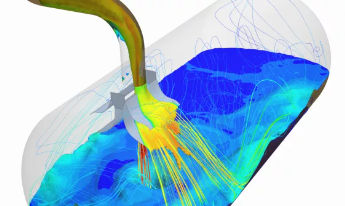

Multiphase Flow Analysis

Multiphase flow analysis includes a simulation of any complex 3D fluid flow involving liquids, gases, and solids as well as any combination of these using CFD.

Engineering Analysis

Erosion Analysis

Erosion analysis uses CFD to predict the erosion rates in pipework and equipment carrying particle-laden fluids to assess the integrity of the system.

Engineering Analysis

Cryo-Freeze & Heat Transfer Analysis

Cryo-freeze and heat transfer analysis are detailed thermal analyses using CFD to solve complex heat transfer problems not readily solvable with other means.

Engineering Analysis

Structural Engineering: Strength, Fatigue & Fracture

Our structural team comprises licensed professionals who perform structural assessments through a combination of calculation and analysis.

Engineering Analysis

Structural Response to Explosion & Fire

Structural response to explosion and fire offers a structural analysis specific to an explosion or fire event to determine the potential levels of escalation and risk to personnel and equipment following a loss of hydrocarbon containment or loss of well control.

Engineering Analysis

Dropped Objects Risk Assessments

Wild Well can provide a dropped object risk assessment to satisfy the latest BSEE requirements.

Engineering Analysis

Forensic Studies

All of the above capabilities can be applied during the planning and design phases of a project but can also be utilized to investigate post-event if something has not worked as planned. By performing a variety of engineering studies, lessons may be learned, and operating practices or designs improved.

Engineering Analysis

Design to Industry Standards

Wild Well experts use both classical methods and FEA to deliver the design of structures and equipment to API, AISC, ASME, DNV, NORSOK, and other Industry Standards.

Engineering Analysis

Fitness for Purpose Assessment

If there is a structural problem, Wild Well’s Advanced Engineering team has the capability to solve it – whether it is designing equipment and skids to meet DNV rules or determining whether a design is fit for purpose.

Life at Wild Well

We provide well control services to oil and gas operators by responding safely and efficiently to emergencies and operational challenges.

Safely Resolving Complex Well Control Events with Advanced Engineering Expertise

Wild Well has established itself as a preeminent global leader in advanced engineering and well control, providing a comprehensive range of services to meet the industry's ever-evolving needs. The company has earned its reputation by effectively addressing the most complex oil and gas incidents worldwide while prioritizing safety, efficiency, and innovation.

Wild Well's highly experienced personnel and customized equipment enable it to respond quickly to any situation in which the integrity of a wellbore or operation is in jeopardy. The company is best known for its emergency response to challenging well control events that elevate the risk/consequence profile on location. With a successful track record of modeling hundreds of wells in various environments, Wild Well specializes in capping operations performed under extreme conditions.

The resolution to a well control event can require a unique skill set beyond the scope of typical drilling operations. Wild Well's engineering team can assist clients in designing and executing remedial efforts to facilitate a return to a standard drilling environment.

Wild Well recognizes the importance of having competent, well control personnel available and knowledgeable about the operations, whether in the office or the field. This approach ensures that the safest and most effective options are available to resolve any well control event. Whether implementing traditional Constant Bottom hole Pressure Methods or non-traditional techniques to regain the primary barrier envelope, Wild Well Control maintains the experience and knowledge to assist clients in safely navigating any well control event.