Xcel

Norman, Oklahoma, United States

Xcel

!

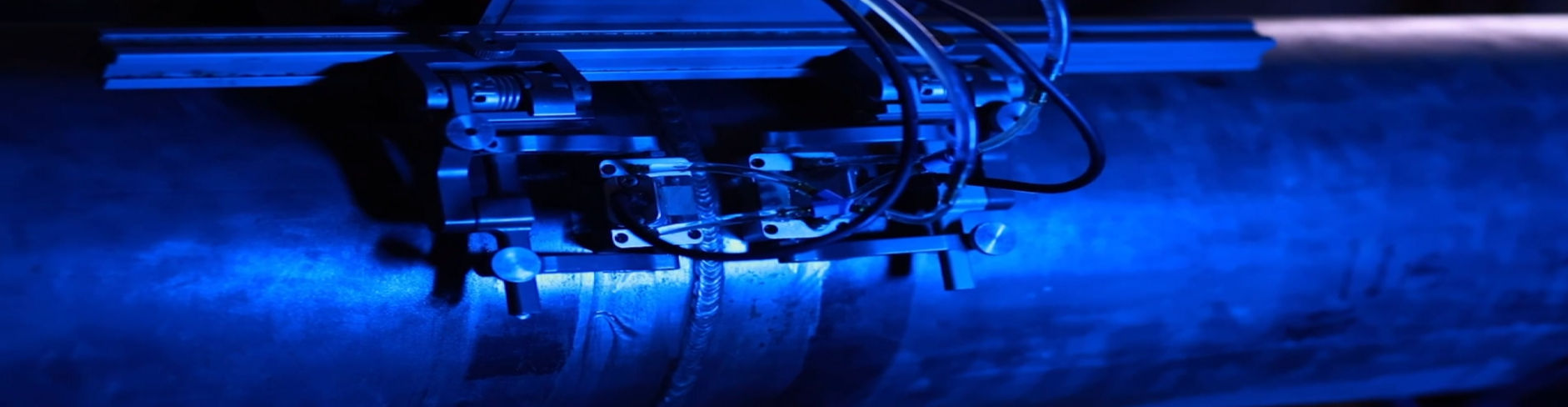

AN INDUSTRIAL INSPECTION COMPANY.

About Xcel

“Delivering Solutions with Integrity” is not just our marketing tag line, it is the company standard and every employee is committed to this expectation. Safety is the number one priority with the understanding that all incidents are preventable through awareness, proper planning, and training.

XCEL IS SYNONYMOUS WITH INTEGRITY

A genuine concern for the safety of our clients and our employees will always be our top priority, along with the condition of their assets, compliance with regulations, their programs, and the quality of products we provide.

INDUSTRIES WE SERVE

At XCEL, we are committed to delivering exceptional services and solutions across a diverse range of industries. Our mission is to provide unparalleled expertise, innovative technology, and dedicated support to ensure the safety, compliance, and operational excellence of our clients. We strive to build long-lasting partnerships by understanding the unique challenges of each industry and delivering tailored solutions that drive success.

Fabrication

XCEL provides NDT and Inspection services, as well as NDT Level III services to number of piping and vessel fabrication facilities. We understand the ASME rules and perform our work in accordance with Code compliant procedures using fully qualified and certified personnel.

Manufacturing

XCEL provides NDT consulting, program management, responsible Level 3 services as well as Conventional and Advanced NDT to manufacturing clients for a number of industries.

Mining

Safety and equipment reliability are essential elements of an efficient mining operation. While distinctly separate programs they are intricately linked. Our NDT and Inspection services can provide valuable information about your assets as well critical testing during maintenance, repair and construction activities.

Petro-Chemical

The Petro-Chemical industry probably utilizes the broadest variety of NDT and Inspection services of any industry. Corrosion investigation, mechanical integrity, construction, maintenance, and repair all require inspection and/or testing to provide information to engineers or meet Code requirements.

What we do