Yoke

Houston, 台中市, Taiwan

Yoke

!

Provider of Products For Fall Protection & Lifting Equipment and Accessories.

About Yoke

YOKE, the professional industrial lifting safety hooks manufacturer, was created in 1985 and focused primarily on trading and virtual manufacturing at the very beginning. At present, on the other hand, the company is devoted to independent research, development, and manufacturing and is known for its innovative technologies in the industry. In 1996, the company started its own brand YOKE and has been competing around the world in response to national industrial upgrading. Over the past more than 30 years, adhering to the belief in developing a “niche-based mainstream market”, the company has survived the trading period (1985-1990), the virtual plant period (1990-1996), and the manufacturing and R&D period (1997-2006) to reach today’s brand marketing period (2007-present). Subsidiaries are available in Mainland China at the moment, and there are about 100 distribution sites around the world. Both quality and technology are well reputed in international society.

Starting in 2009, the company has been devoted to strategic transformation and innovation. The overall development strategy emphasizes “beautiful products, fair prices, fast out, and fast in” and has rendered overwhelming operational fruit to date, securing the company’s leading position in the world of lifting chains and hooks. Factory 2 was added to the industrial park in Taichung in September 2017 to take care of mainly the assembly and production of fall-proof safety equipment and fittings for high altitude operations. To address the growth in the number of purchase orders, existing production lines were moved to Factory 2. In addition, more production lines were added so that customers’ needs may be fulfilled. Our new factory for aluminum processing at Chuansing Industrial Park in Changhua County was inaugurated in December 2018 as we completed the first phase of the project. We plan to offer more diverse products to our customers in the future.

In the industry for safety hooks, all products are distributed on the basis of the safety and protection they provide. And as such, YOKE has defined itself as a company that deals and sells safety. “Pursue quality perfection, Constant innovation and development, Sustain management improvement and Create customer satisfaction” has always been the Company’s management philosophy, and we have always insisted on “quality and safety” over the years. All hooks used in lifting projects go through necessary tests as required by applicable regulations. In addition to API TS 29001, API QMS ISO 9001, and DNV ISO 9001, type approvals have been obtained for products in multiple countries at the same time, including the related product safety certifications granted by the German Social Accident Insurance Association (DGUV), the American Bureau of Shipping (ABS), the Det Norske Veritas (DNV), and the Canadian Standards Association (CSA).

In order to meet the needs for global deployment in the future, YOKE has introduced the SAP system since 2008 and combined its management practice. By integrating information system effectively and improving the overall production and management efficacy, the overall corporate resource planning and utilization efficacy can be strengthened and thus the company competitiveness can be increased.

As the world strives to reach the goal of sustainable development, Yoke has developed to two main axes in intelligent manufacturing and digital platform. Between interacting with related personnel such as shareholders, customers, employees, suppliers, and academic associations, our internal continuous improvement, “Accountability and integrity, Appropriate decisions, Acquire customer loyalty, Active learning, Aggressive innovation” core value, and 8 operational goals are keeping to present YOKE operational value – Safety!

Description of Services

Milestones:

2019

YOKE has joined Center for Corporate Sustainability and become one of the influential bellwethers contributing to corporate sustainability in Taiwan.

2018 Corporate Sustainability Report, verified by SGS

Certificated to ISO14001:2018、ISO 45001:2018.

2018

Establishment of aluminum forging production line at the new facility in Chuansing Industrial Park in Changhua County

2017 Corporate Sustainability Report, verified by a third party (SGS)

Passed the audit of CSR evaluation from PETZL(one of the customer of YOKE) and NGO.

Introduced the Windchill PLM system to control product lifecycle.

Introduced the Salesforce Sales Cloud system for the enhancement of systematic management.

Introduced the RFID Inspect APP as the value-added service of products.

2017

Established an assembly line for fall protection equipment in Factory 2 located at Gongyequ 3rd Road, Taichung

National Taiwan University College of Engineering ─ YOKE Technology Research and Development Center was established.

In response to the production traceability and quality control, introduced the MES system.

2016

Introduced the Abaqus system.

2015

Ranked 93th in terms of profitability in CommonWealth Magazine's “Top-2000 Manufacturers in Taiwan”

Shackle (DA) obtained DNV2.7-1 certification from Det Norske Veritas

Obtained certifications from American Petroleum Institute (API) Specification Q1: Quality Management and API 8C: Hoisting equipment

2014

Ranked top 1000 in CommonWealth Magazine's “Top-2000 Manufacturers in Taiwan” for the first time

2013

Obtained product quality certification from National Petroleum Construction Company (NPCC) in UAE

2010

Established Mainland subsidiary to facilitate venture into the Mainland market.

2009

YOKE's corporate headquarter was officially commissioned.

2007

Introduced SAP ERP (Enterprise Resource Planning) to support worldwide deployment and operational integration.

Obtained certifications for API QMS ISO 9001 and API Specification Q1

2006

Obtained certification for ISO 9002 - Quality Systems from SGS

Obtained certification for ISO 9001 from DNV (Norway)

Obtained certification from American Bureau of Shipping (ABS)

2001

Acquired land and constructed factory at Gongyequ 33rd Road, Taichung, to accommodate production line expansion and the growing business.

1999

YOKE procured a parcel of land at Road 34 of the Taichung Industrial Park to set up the company's factory.

1985

YOKE Industrial Corp. was founded. Specialist trading for chains and steel cable hook accessories.

What we do

Pioneer of Safety

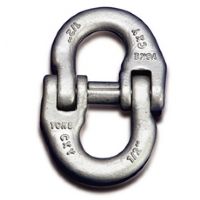

YOKE is a professional industrial lifting safety hooks manufacturer established in 1985. With a mission to “manufacture quality hooks and safety equipment for humankind to enjoy better safety protection anywhere anytime,” we demonstrate our pursuit of continual improvement in sustainable safety value in terms of technology, product, process, organization and marketing through two main product ranges: the “8-series” of industrial lifting chain fittings and the “N-series” of personal protection equipment (PPE).

We started operations with trading and virtual manufacturing. In 1996 we began to vie for the global industrial lifting hook market with our own brand “YOKE”, while offering OEM services for world-leading PPE manufacturers at the same time to continuously create value for global industrial safety through product design, quality certification, and materials R&D. In recent years we started “digital transformation” and have successfully developed “Tech for Safety” technologies and products to lead a reform in the industrial safety industry by embedding RFID chips in products and using cloud software. With such, we constantly realize the business philosophy of “pursuit of quality optimization, ceaseless innovation and R&D, continual management improvement, creation of customer satisfaction”.

Life at Yoke

Path of development

The path of YOKE’s development is characterized by four different phases, as the Company adjusted its operational model based on the concept of a “niche-based mainstream market.” In 2019 we re-planned our operational strategy to pursue targets for optimal expansion. We actively engaged in the digital transformation of products to comply with global occupational safety standards from product traceability, product maintenance, product operation, etc. Through platform integration and cloud high-tech technology, we actively promote the digitization of industrial safety.