You Will Get Consultation on Acid / Chemical Treatments

Share

Description of Consultation

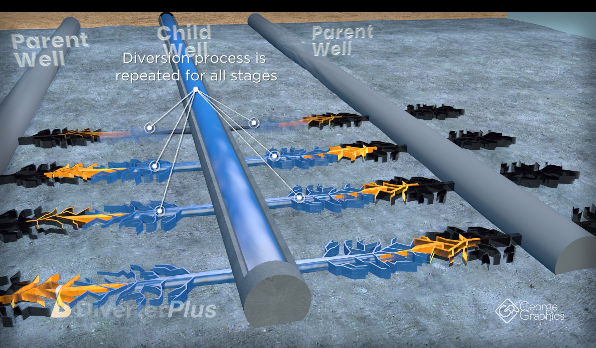

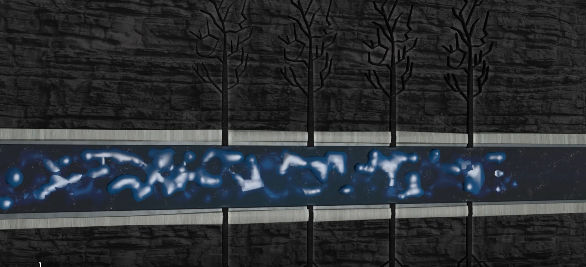

DiverterPlus products are temporary diverting materials used to improve the distribution of treating fluids across multiple perforations or openhole intervals. During placement, Div+ and RapidVert+ are solid non-toxic particles capable of blocking perforation tunnels, formation faces, and fractures near the wellbore. After a pre-determined length of time, the diverter will hydrolyze into a clear, non-hazardous liquid. This process is driven simply by time and bottom-hole temperature, meaning that no additional remedial work is required. DiverterPlus blends are optimized for transport and plugging performance in the low rate/high leakoff environment of acid/chemical treatments.

Key Design Factors

- Maximize matrix conductivity

- Particles designed for optimized transport in low rate/low viscosity applications

- Reduced time/expense

Benefits and Outcomes

- Ensure acid/chemicals are distributed evenly across entire stimulated interval

- Increased duration between treatments

- Predictable time to production

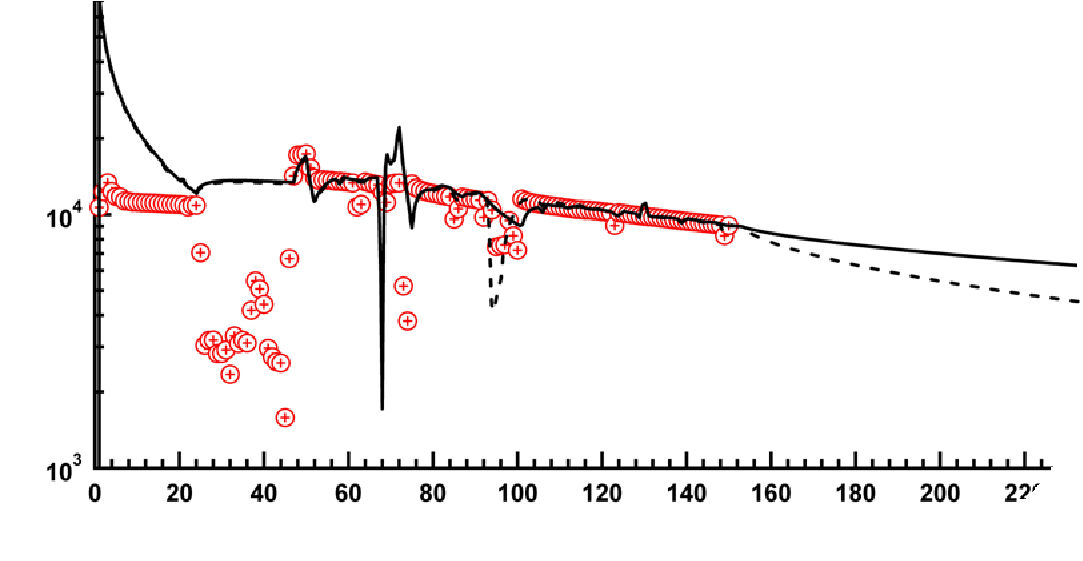

The low rate designs that are often associated with acid and chemical treatments can make it difficult to determine the effectiveness of diversion by traditional pressure response analysis alone. As such, DiverterPlus encourages our customers to also determine success based upon long term production analysis. Treatment effectiveness can be determined by analysis of the rate and magnitude of production decline. The Chart above illustrates the shallow decline rate when using optimized diversion materials such as Div+ and RapidVert+ versus using traditional diverters. The reduced decline frequently means periodic treatments are needed less often, substantially reducing operating costs.

What you will get from meeting with me

You Will Get Consultation on Acid / Chemical Treatments

Things I can do. Things I can offer

You Will Get Consultation on Acid / Chemical Treatments

My Classification

Energy Service Company,Engineering Company,Consulting Company,Contractor,Sub-Contractor,Research Institution

My Experience Level

Senior

About Samer Shwayat

In his role as a Technical Solutions Specialist, Sam employs his extensive experience in the drilling and cementing segments to spearhead DiverterPlus’ efforts in those markets. Sam assists in new product development and brings unique technologies and capabilities to help drive DiverterPlus’ service-oriented customer philosophy.

Sam Shwayat graduated from Oklahoma State University in Stillwater Oklahoma with a BS in Electrical Engineering. Upon Graduation, Sam began his Oilfield Services career with Schlumberger as a cementing field engineer followed by 11+ years of different positions within the Schlumberger cementing service line including field service management, project coordination, technical sales, and supply chain management. Sam time with Schlumberger took him around the world to a variety of locations including Oklahoma, NW Texas, Saudi Arabia, and Midland before finally settling in the Houston area while with Schlumberger. Sam then Joined a nitrogen equipment manufacturer serving the oil and gas industry with onsite N2 generators as a technical sales engineer.

Ratings & Reviews

No Ratings & Reviews given yet..

More Consultations From Samer Shwayat

You Will Get Consultation On Drillout & Cleanout Services

Samer Shwayat

400/hr

You Will Get Consultation On Offshore Solvent & Scale Treatment Services

Samer Shwayat

400/hr

Similar Consultations (Recommended consultations)

Southwest Pinnacle Exploration Limited

250/hr

RenaServ (Renaissance Oilfield Services)

250/hr

Frederick Geosciences, LLC

1000/hr

W.W. Little Geological Consulting, LLC

500/hr

Daly & Inamdar, Advocates

500/hr

Strategic Sales International ApS

250/hr