SEISMIC SOLUTIONS - GAUGE MONITORING SYSTEM

Share

Description of Service

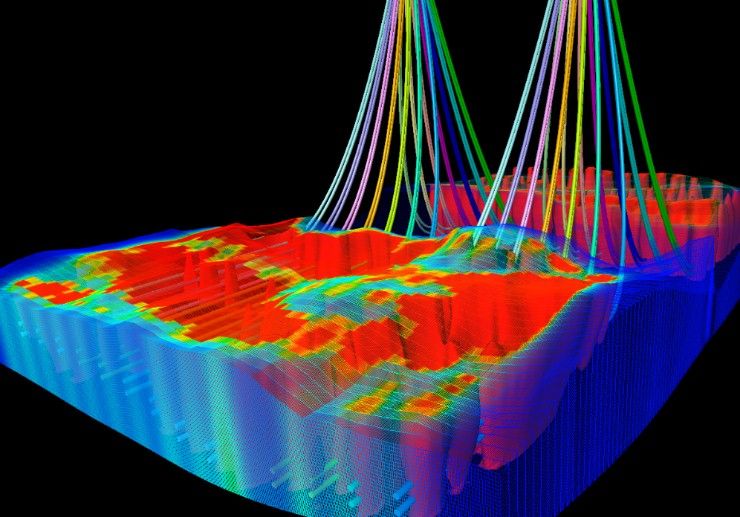

We have partnered with leading seismic equipment manufacturers, to provide the industry with superior products and leading-edge technology in Seismic Solutions. We offer our product range in various specifications in order to fulfill the variegated requirements of the client covering a wide product range specialized for 2D/3D Seismic Data Acquisition & Processing.

GAUGE MONITORING SYSTEM

1. Electric Submersible Pump Gauges

GRC’s ESP Sensor is reliable, rugged, durable and easy to install and operate. Combined with a service team of experienced professionals, accurate data from your well to your desktop is just a click away. GRC’s broad product offering is designed for reliability regardless of the environment. For standard wells, GRC offers ESP sensor systems using rugged, accurate parallel plate gap capacitance transducers. When greater reservoir accuracy is needed, GRC offers ESP Quartz and Piezo sensors.

2. Gas Lift Gauges

When other artificial lift systems fail, especially Electric Submersible Pumps (ESPs), the result is immediately obvious and often catastrophic. However, a gas-lift system that is operating incorrectly may not be noticed for weeks or even months. A lower field and possibly well production rate will be noted, but could be attributed to reservoir inflow damage, a change in water cut, or simply a production allocation or well test measurement error. In reality, a production advantage is being lost that can rapidly account for tens of thousands of barrels of oil. An intelligent surface control and optimization system, incorporating the use of Sercel-GRC’s line of downhole gauges and surface data acquisition equipment, can be used to provide an instant warning of a change in operating behavior in a well, which will allow quick operator action and resolution of optimum production rates. In addition, a normally operating gas-lift system can be continuously optimized by proper allocation of injected gas in order to react to events such as change in gas-lift supply volume, change in manifold pressure, or water cuts.

3. Progressive Cavity Pump Gauges

Monitoring downhole pressure data can be used to increase pump speed to keep reservoir pressure down to allow for optimal production. Installing a downhole gauge gives the ability to monitor reservoir fluid level and prevent damage to the downhole equipment caused from dry pumping. Gauge parameters can be used to monitor pump efficiency and to act as an early warning system to prevent premature equipment failure.

4. Sucker Rod Pump Gauges

Increase production by maintaining the lowest possible uid level over pump. Avoid premature pump-off due to inaccurate algorithms Improve control over motor speed by monitoring real time bottom hole data. Enable automated decision making using measurements, not assumptions or calculations. Verify pump con guration’s actual performance and efficiency Reduce lifting cost and extend life of pump.

What You Will Get From Purchasing This Professional Service. Deliverables

SEISMIC SOLUTIONS - GAUGE MONITORING SYSTEM

Duration To Complete Service. How Long Before Service Is Completed

1-3 months

Pan India Group, started operations in 1985, Provides Services in Oil & Gas, Mining, Geographical Management System (GSI), Remote Sensing and Photogrammetry and represents a wide spectrum of OEMs covering diverse customer base including Railways, Oil, Gas, Defence, Power, Nuclear, Space, Scientific Labs and Research organization, Public & Private Sector in India and neighbouring countries. The Group has been instrumental in bringing new technologies into India from countries like USA, Canada, UK, France, Italy, Germany , Russia and Japan backed by a complete range of start-up and support services, facilitating absorption of state-of-the-art technology. The Group today has a large pool of talent in the areas of system integration consultancy, marketing and after sales services. The group employs over 300 motivated staff.

Ratings & Reviews

No Ratings & Reviews given yet..

More Professional Services From Pan India Consultants Pvt. Ltd.

LAND SURVEY SOLUTIONS - GNSS SURVEYING

Pan India Consultants Pvt. Ltd.

10,000.00 - $1,000,000.00

LAND SURVEY SOLUTIONS- OPTICAL SURVEYING

Pan India Consultants Pvt. Ltd.

10,000.00 - $1,000,000.00

LAND SURVEY SOLUTIONS - SOFTWARE SOLUTIONS

Pan India Consultants Pvt. Ltd.

10,000.00 - $100,000.00

LAND SURVEY SOLUTIONS - GIS MOBILE MAPPING

Pan India Consultants Pvt. Ltd.

10,000.00 - $1,000,000.00

LAND SURVEY SOLUTIONS - DATA COLLECTOR

Pan India Consultants Pvt. Ltd.

10,000.00 - $1,000,000.00

LAND SURVEY SOLUTIONS - TERRESTRIAL LIDAR

Pan India Consultants Pvt. Ltd.

10,000.00 - $500,000.00

LAND SURVEY SOLUTIONS - MOBILE LIDAR

Pan India Consultants Pvt. Ltd.

10,000.00 - $100,000.00

LAND SURVEY SOLUTIONS - UNMANNED AERIAL VEHICLE

Pan India Consultants Pvt. Ltd.

10,000.00 - $100,000.00

MARINE SURVEY SOLUTIONS - TRIMBLE MARINE CONSTRUCTION (TMC) SYSTEMS

Pan India Consultants Pvt. Ltd.

10,000.00 - $100,000.00

Similar Services (Recommended services)

Southwest Pinnacle Exploration Limited

100,000.00 - $50,000,000.00

GPG SERVICES S.A.

5,000.00 - $250,000.00