You Will Get Consultation On Seismic Petrophysics Services

Share

Description of Consultation

Traditional methods and techniques for log data interpretation that have been successfully used for conventional reservoirs are not applicable to shale plays, so operators have been developing shale deposits with limited data, essentially blindfolded. As a result, the focus has shifted to cost control and drilling efficiency. The popular ‘factory drilling’ or ‘geometric’ approaches would be ideal for homogeneous formations, but as is well known, shale plays are very inhomogeneous vertically and laterally. These approaches reduce the cost of drilling a single well, but increase overall development costs and environmental impact because they result in drilling and fracking a large number of low producing wells and zones. Fracking rocks with high brittleness reduces the cost of completion, but often misses the highest producing formations.

ShaleVision™ changes the paradigm by identifying good and bad zones, allowing operators to focus on developing only the highest producing wells. It provides shale operators with the locations of the highest volumes of movable hydrocarbons that previously had only been visible for those rare wells with special core or cuttings analyses. The information ShaleVision™ provides can lead to tenfold increases in production with twice or three times the recovery efficiency.

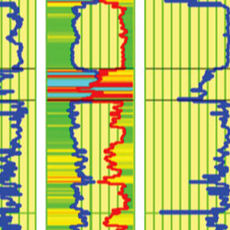

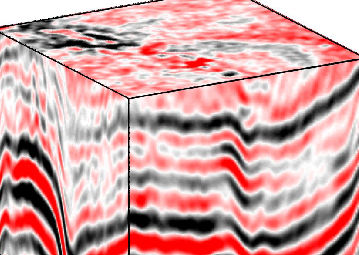

ShaleVision™ uses advanced formation evaluation techniques to generate a proprietary Production Profile that shows predicted production in barrels per day as well as brittleness along the entire well. The input data for this technology can be limited to only standard open-hole log data: gamma ray, resistivity, neutron and density porosity.

Adjusting the coefficients of the basic equation for calculating Production Profiles for various reservoirs (calibration) enhances the accuracy of predictions. Data for calibration include open-hole log data, fracking intervals and production history. Because of the nature of the technology, more calibration data result in more accurate interpretation. Each new well contributes to the tuning of the model, so that each subsequent well is processed more accurately than the previous one.

A Production Profile for a vertical well allows identification of the highest producing formations and fracking zones. Production Profiles for a group of vertical wells allow mapping of the best spots and identification of the best locations and trajectories of horizontal wells. ShaleVision™ removes the blindfolds.

What you will get from meeting with me

You Will Get Consultation On Seismic Petrophysics Services.

Things I can do. Things I can offer

You Will Get Consultation On Seismic Petrophysics Services.

My Classification

Energy Service Company,Engineering Company,Consulting Company,Contractor,Sub-Contractor

My Experience Level

Senior

About Vladimir Ingerman

Dr. Ingerman received a Doctor of Technical Science, as well as a Ph.D. in oil field development, and a Master of Science in geophysical methods. He has 55 professional publications including two books. He founded Amros Corporation in 1994.

Global Petroleum Show 2018 recognized Amros Corporation as an Award Winner in the category Innovations in Technologies: Process Controls. World Oil Awards 2016 recognized Amros Corporation as a Finalist in the category New Horizons Idea. RICE Alliance recognized Amros Corporation an Award Winner in the category Energy and Clean Technology in 2015.

He was VP of Tyumenneftegeophysica, the second largest Service Company in the Oil Ministry. In this company he was in charge of development and implementation of the software for automated processing and interpretation of log data. This software captured almost 100% of oil and gas wells in Western Siberia - the largest oil and gas region in Former Soviet Union and is still in use. The total number of the wells where software was applied exceeded a million.

He has advised all major Russian oil companies, Schlumberger, Halliburton, Amoco, Shell, El Paso and others in the US, most major oil companies in South America, Maersk Oil in Denmark and ONGC in India.

Ratings & Reviews

No Ratings & Reviews given yet..

More Consultations From Vladimir Ingerman

Over 30+ years On Various Conventional/Unconventional Field Developments.

Vladimir Ingerman

3000/hr

You Will Get Consultation On Single & Group Well Analysis

Vladimir Ingerman

3000/hr

You Will Get Consultation On Seismic Petrophysics Services

Vladimir Ingerman

3000/hr

You Will Get Consultation On Feasibility Studies For Field Development

Vladimir Ingerman

3000/hr

You Will Get Consultation On Optimization Of Shale Developments Based On Our Proprietary ShaleVision™ Technology

Vladimir Ingerman

3000/hr

Similar Consultations (Recommended consultations)

A.B. Electrical Works

100/hr

National Engineering Services Pakistan (Pvt.) Limited (NESPAK)

1000/hr

Southwest Pinnacle Exploration Limited

250/hr

XRS Consulting Engineers CC

400/hr